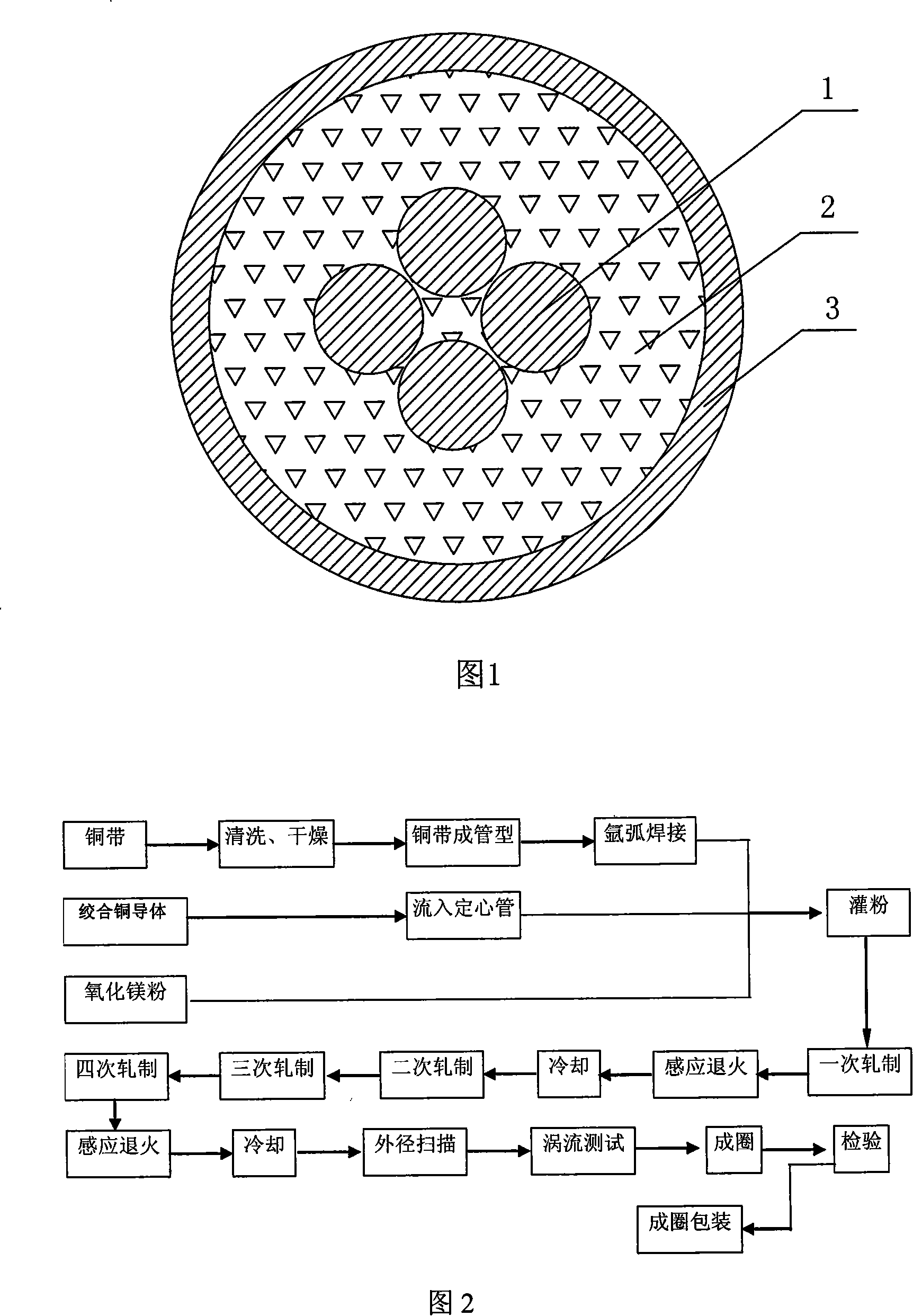

Mineral insulation signal cable and method for manufacturing the same

A signal cable, mineral insulation technology, used in insulated cables, cable/conductor manufacturing, communication cables, etc., can solve problems such as loss of life and property, and achieve the effect of improving moisture absorption, scientific and reasonable structure, and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] After the copper strip is cleaned and dried, the copper strip is longitudinally wrapped into a tube shape, and the edge of the copper strip is argon-arc-welded under the protection of argon gas to form a seamless copper sheath 3 at a welding speed of 2m / min. The high-purity magnesium oxide powder is prepared by calcining the magnesium oxide powder at a high temperature to remove impurities and evenly adding 0.06% to 0.08% of silicon oil (polydimethylsiloxane) by weight. The copper wire core stranded by copper wire is used as the conductor 1, and the stranded copper wire core conductor 1 enters the central part of the seamless copper sheath 3 through a fixed pipe (flowing into the centering pipe). A filling machine is used to fill high-purity magnesium oxide powder insulation 2 in the gap around the twisted copper core conductor 1 in the seamless copper sheath 3 to make a semi-finished cable. The outlet of the pipe is set under the weld, and the magnesium oxide powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com