A classification method for iron and steel materials combined with laser-induced breakdown spectroscopy

A technology of laser-induced breakdown and classification method, applied in the field of spectral analysis, can solve problems such as long detection time, difference in composition, performance, and complicated steps, and achieve the effect of improving prediction accuracy, reducing calculation cost, and improving prediction ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

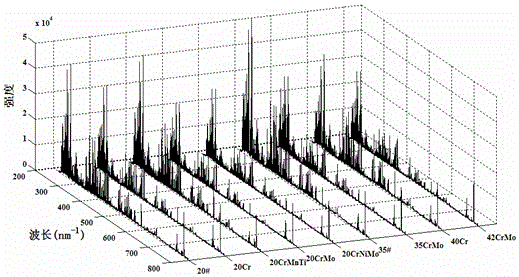

[0058] Taking the modeling and classification of nine different grades of round steel samples as an example, the operation process of the present invention will be further described in conjunction with the accompanying drawings and examples, but the present invention is not limited to this example.

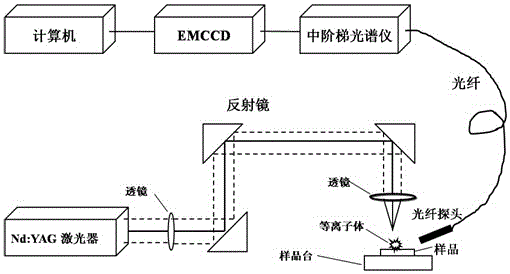

[0059] The LIBS system used in this example is mainly composed of a Q-switched pulsed Nd:YAG laser, an echelle spectrometer (ARYELLE-UV-VIS, LTB150, German), a movable sample stage and a computer, such as figure 2 shown. The laser energy is 61mJ, the fundamental frequency light wavelength is 1064nm, the pulse width is 10 ns, the repetition frequency is 10Hz, and the spectral range is 220nm-800nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com