Circular weaving machine weft insertion device with reducing function

A technology of circular looms and weft inserters, applied in circular looms, looms, textiles, etc., can solve the problems of low adjustment accuracy, inability to adapt to the real-time diameter change of the size ring, and inability to adjust angles, etc., to achieve high adjustment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

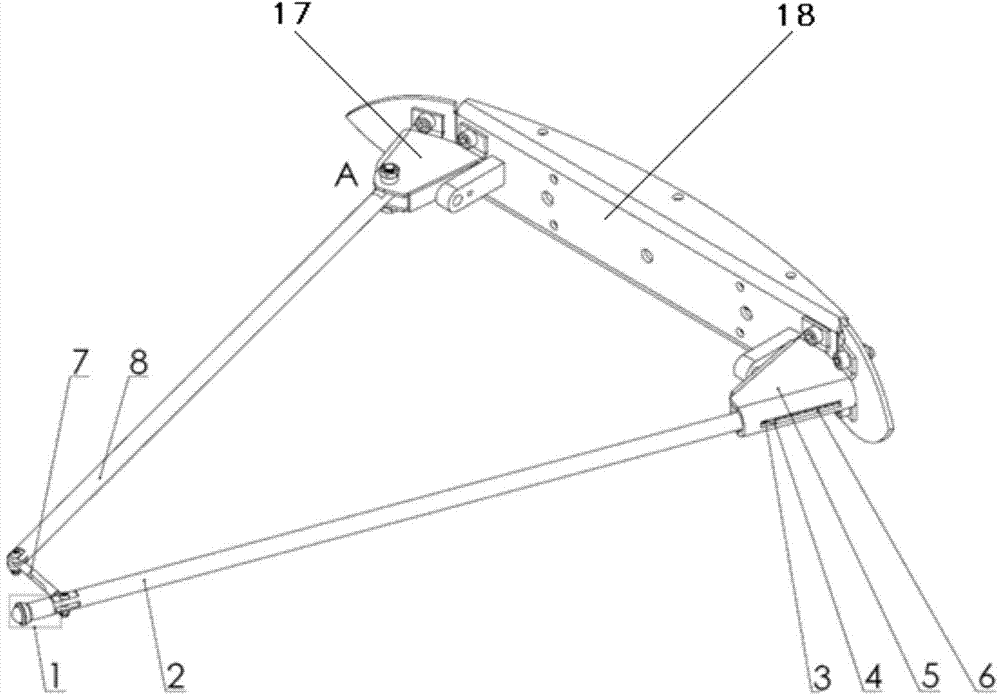

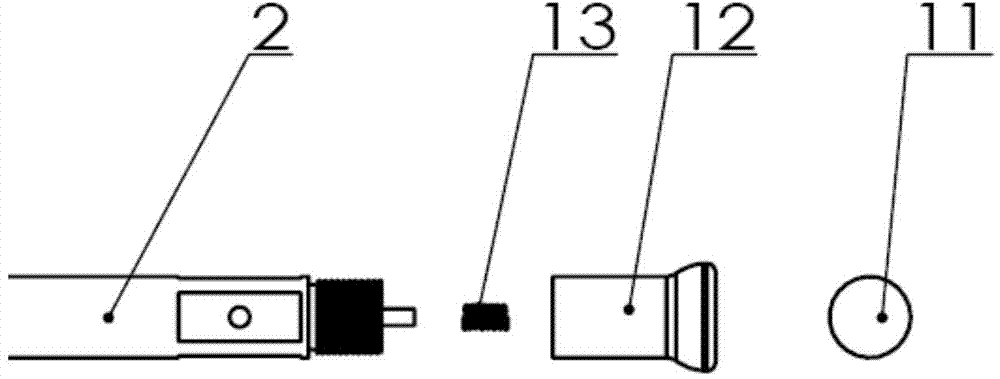

[0021] Such as Figure 1 ~ Figure 3 As shown, a circular loom weft insertion device with diameter changing function includes a weft squeezing device 1 at the front end of the shuttle arm and an adjustable shuttle arm mechanism. The weft squeezing device 1, such as figure 2 As shown, it includes a steel ball 11, a ball sleeve 12, and a second spring 13. The steel ball 11 is closely attached to the weft yarn at the weaving fell, and at the same time it is rolling friction with the yarn to reduce damage to the yarn. It is suitable for carbon fiber, glass Fiber and other brittle materials; the adjustable shuttle arm mechanism includes the left shuttle arm 2, the compression first spring 3, the block 4, the middle connecting rod 6, and the middle connecting rod 7; The front end of the shuttle arm is affected by the tension of the yarn, the length of the left shuttle arm 2 changes, the middle connecting rod 7 rotates around point A, and the relative angle between the middle connec...

Embodiment 2

[0023] Such as Figure 4 ~ Figure 6 As shown, a circular loom weft insertion device with diameter changing function includes a weft squeezing device 1 at the front end of the shuttle arm and an adjustable shuttle arm mechanism. The weft squeezing device 1, such as Figure 5 As shown, including deep groove ball bearing 14 and bearing sleeve 15, deep groove ball bearing 14 and bearing sleeve 15 interference fit; described deep groove ball bearing is connected with left shuttle arm 2, right shuttle arm 8 bolts, guarantees bearing sleeve 15 The yarn at the weaving fell is rolling friction, which reduces the damage to the yarn, and is applicable to brittle materials such as carbon fiber and glass fiber; the adjustable shuttle arm mechanism includes a left shuttle arm 2, a compressed first spring 3, Stopper 4, right curved shuttle arm 9, third spring 16 and right shuttle arm extension rod 10, during the weaving process, when the diameter of the cloth fell changes, the rollers at th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap