A method for observing the metallographic structure of copper-nickel/steel surfacing interface

A technology of metallographic structure and copper-nickel, which is applied in the observation field of copper-nickel/steel surfacing interface metallographic structure, can solve the problems such as difficult to obtain the interface structure, achieve the interface metallographic structure to be clearly visible, avoid serious erosion effects, and easily The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

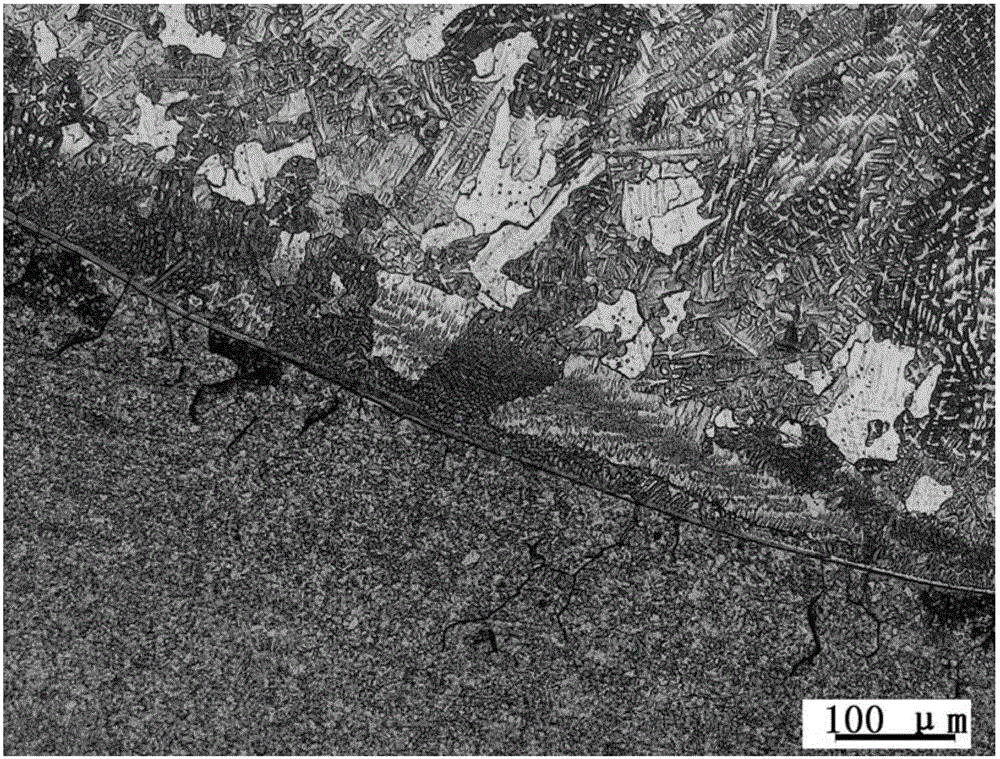

[0020] Observation of interface metallographic structure of copper-nickel with thickness 16mm Q235 steel plate surfacing welding thickness 8mm:

[0021] Step 1: Machining a metallographic observation plane at the copper-nickel / steel surfacing interface, and then using the machined metallographic observation plane on a metallographic grinding machine with 150 # and 700 # The metallographic water sandpaper is ground step by step, and the grinding direction is rotated 90° every time the grain size sandpaper is changed to ensure that the last grinding trace is completely eliminated, and the sand grains on the metallographic observation plane are washed away after grinding;

[0022] Step 2. Place the metallographic observation plane where the sand grains have been washed out in step 1 on the polishing machine, and use Cr 2 o 3 Solution and diamond powder with a particle size of 2.5 μm are mechanically polished until there are no scratches and drags on the surface of the metallogr...

Embodiment 2

[0027] Observation of the interface metallographic structure of 16MnR steel plate with a thickness of 10mm and copper-nickel with a thickness of 8mm:

[0028] Step 1: Machining a metallographic observation plane at the copper-nickel / steel surfacing interface, and then using the machined metallographic observation plane on a metallographic grinding machine with 150 # and 700 # The metallographic water sandpaper is ground step by step, and the grinding direction is rotated 90° every time the grain size sandpaper is changed to ensure that the last grinding trace is completely eliminated, and the sand on the metallographic observation plane is washed away after grinding;

[0029] Step 2. Place the metallographic observation plane where the sand grains have been washed out in step 1 on the polishing machine, and use Cr 2 o 3 Solution and diamond powder with a particle size of 2.5 μm are mechanically polished until there are no scratches and drags on the surface of the metallograp...

Embodiment 3

[0034] Observation of the interface metallographic structure of 16MnR steel plate with a thickness of 10mm and copper-nickel with a thickness of 8mm:

[0035] Step 1: Machining the metallographic observation plane at the copper-nickel / steel surfacing interface, and then using the metallographic observation plane on the metallographic grinding machine successively with 150 # and 700 # The metallographic water sandpaper is ground step by step, and the grinding direction is rotated 90° every time the grain size sandpaper is changed to ensure that the last grinding trace is completely eliminated, and the sand on the metallographic observation plane is washed away after grinding;

[0036] Step 2. Place the metallographic observation plane where the sand grains have been washed out in step 1 on the polishing machine, and use Cr 2 o 3 Solution and diamond powder with a particle size of 2.5 μm are mechanically polished until there are no scratches and drags on the surface of the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com