A method for observing metallographic structure of industrial pure hafnium

A metallographic structure, industrially pure technology, applied in the field of observation of industrial pure hafnium metallographic structure, can solve problems such as difficult to obtain clear structure, achieve easy control and mastery, avoid misjudgment, smooth and bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

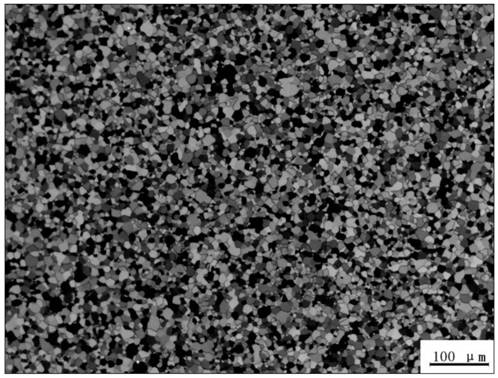

Embodiment 1

[0033] The observation method of the present embodiment comprises the following steps:

[0034] Step 1. Machining a metallographic observation plane on the surface of an industrial pure hafnium bar with a specification of Φ12mm, and then grinding the machined metallographic observation plane on a metallographic grinder. # 、500 # , 800 # and 1000 # The metallographic water sandpaper is ground step by step, and the grinding direction is rotated 90° every time the metallographic water sandpaper is replaced to ensure that the last grinding trace is completely eliminated, and the sand grains on the metallographic observation plane are washed away after grinding;

[0035] Step 2, immerse the metallographic observation plane of the grit in step 1 and immerse it in the chemical polishing solution and polish it for 30s; the chemical polishing solution is composed of ethanol, hydrogen fluoride, deionized water, concentrated sulfuric acid and deionized water according to 4:1:10: The v...

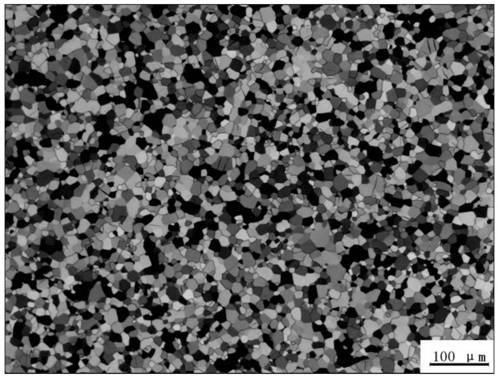

Embodiment 2

[0041] The observation method of the present embodiment comprises the following steps:

[0042] Step 1. Machining a metallographic observation plane on the surface of an industrial pure hafnium bar with a specification of Φ20mm, and then grinding the machined metallographic observation plane on a metallographic grinder. # 、500 # , 800 # and 1000 # The metallographic water sandpaper is ground step by step, and the grinding direction is rotated 90° every time the metallographic water sandpaper is replaced to ensure that the last grinding trace is completely eliminated, and the sand grains on the metallographic observation plane are washed away after grinding;

[0043] Step 2, immerse the metallographic observation plane of the grit in step 1 and immerse it in the chemical polishing solution and polish it for 45s; the chemical polishing solution is composed of ethanol, hydrogen fluoride, deionized water, concentrated sulfuric acid and deionized water according to 5:1:12: The v...

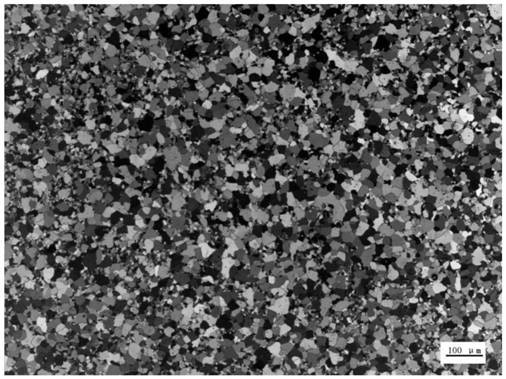

Embodiment 3

[0048] The observation method of the present embodiment comprises the following steps:

[0049] Step 1. Machining a metallographic observation plane on the surface of an industrial pure hafnium bar with a specification of Φ16mm, and then grinding the machined metallographic observation plane on a metallographic grinder. # 、500 # , 800 # and 1000 # The metallographic water sandpaper is ground step by step, and the grinding direction is rotated 90° every time the metallographic water sandpaper is replaced to ensure that the last grinding trace is completely eliminated, and the sand grains on the metallographic observation plane are washed away after grinding;

[0050] Step 2, immerse the metallographic observation plane of sand grains in step 1 into the chemical polishing solution and polish for 60s; the chemical polishing solution is composed of ethanol, hydrogen fluoride, deionized water, concentrated sulfuric acid and deionized water according to 6:2:12: The volume ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com