T-shirt with fabric provided with variable patterns and hollowed-out back part

A short-sleeved, textured technology, applied in the field of clothing, can solve problems such as discomfort, poor wearing effect, and poor ventilation performance of short-sleeved sleeves, and achieve the effects of increasing aesthetics, improving ventilation performance, and increasing density and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

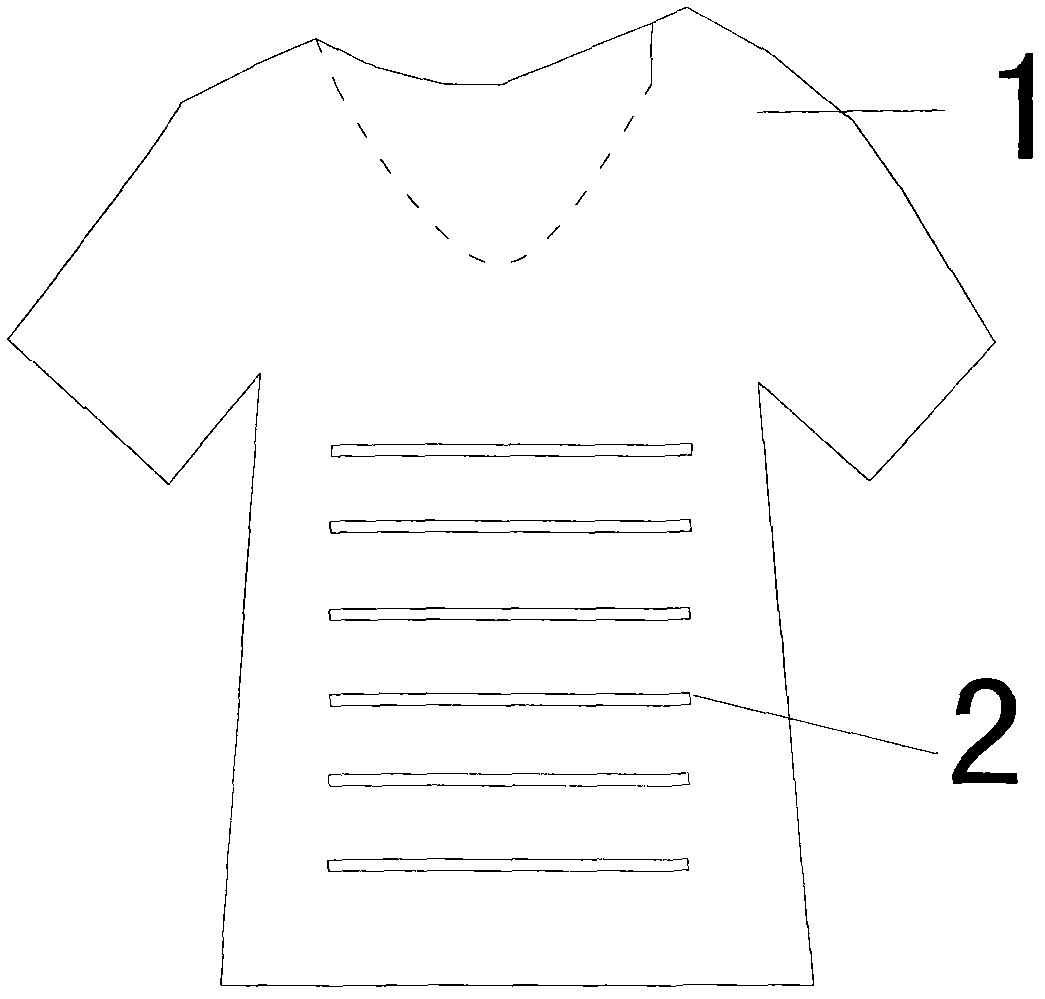

[0012] see figure 1 , the present invention relates to a short-sleeved short-sleeve with a changed fabric texture and a hollowed-out back piece. , the hole is hollowed out in a quincunx shape, a circle or a heart shape, the short-sleeved body 1 is made of a three-phase braid, and the three-phase braid is formed by interweaving yarns, and the yarns include weft yarns, It also includes left-inclined warp yarns, right-inclined warp yarns, among the left-inclined warp yarns and right-inclined warp yarns, the weaving rule is: a weft thread passes from under a left-inclined warp yarn to the adjacent right-inclined warp yarn, and then enters the next left-inclined warp yarn. under the warp yarns, and weaving in this way; and the weft yarns adjacent to said weft yarns are passed from under one right-leaning warp yarn to over the next left-leaning warp yarn, and then under the next right-leaning warp yarn, and so on Weave on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com