An instrument for measuring mechanical impurities in crude oil and petroleum products

A technology for petroleum products and mechanical impurities, applied in the field of mechanical impurity analyzers, can solve the problems of inconvenient operation, affecting mechanical efficiency, large consumption of samples and solvents, etc., to achieve less impact on operators and the environment, improve accuracy and Effects of stability, low sample and solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

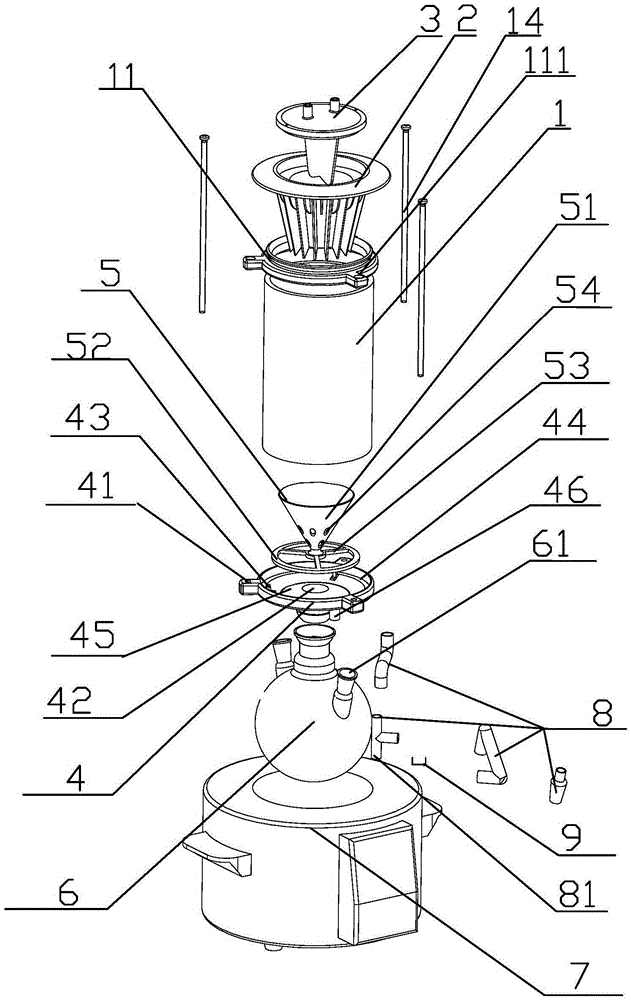

[0014] Such as figure 1 The one shown includes an extraction cylinder 1, the upper opening of the extraction cylinder 1 is sleeved with a ferrule 11, and a heat exchanger 2 composed of heat conduction fins is inserted on the ferrule 11, and a condenser is inserted in the heat exchanger 2 3. There are three upper fixing ears 111 on the ferrule 11, the base 4 is connected to the lower opening of the extraction cylinder 1, three lower fixing ears 41 are arranged on the base 4, and there is a The fixed rod 14 is placed on the base 4 with a perforated funnel 5 with a drip hole 54 on the edge. The perforated funnel 5 includes a funnel body 51 and a rest ring 52, and three connections are arranged between the rest ring 52 and the bottom of the funnel body 51. Rod 53, the base 4 is provided with three buckles 43 that snap into the rest ring 52, the middle of the base 4 is provided with an air guide tube 42, the air guide tube 42 is plugged with the flask 6, the bottom of the flask 6 i...

Embodiment 2

[0016] It is basically the same as Example 1, except that there are no upper and lower fixing ears, no fixing rods, and the base is screwed to the extraction cylinder, and no return port, transfer port, or return pipe are provided.

[0017] When testing crude oil and petroleum products, after the electric heating mantle heats the distillation flask, part of the solvent in the flask becomes organic vapor, which gradually rises to the condenser through the channel of the air guide tube in the base; the organic vapor drops along the heat exchange plate after being cooled to liquid It falls on the filter paper and forms a mixed solution with the sample in the filter paper; the mixed solution penetrates the filter paper, passes through the hollow funnel, and flows to the base of the extraction device. in the distillation flask. The organic solvent is heated again to become an organic vapor and enters the extraction device, so that the extraction is carried out in a cycle. The oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com