Pull head for laying cables

A technology for laying cables and pulling heads, which is applied in the electrical field, can solve problems such as time-consuming, high manufacturing cost, and cumbersome cable connection process, and achieve the effects of simple structure, convenient installation, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

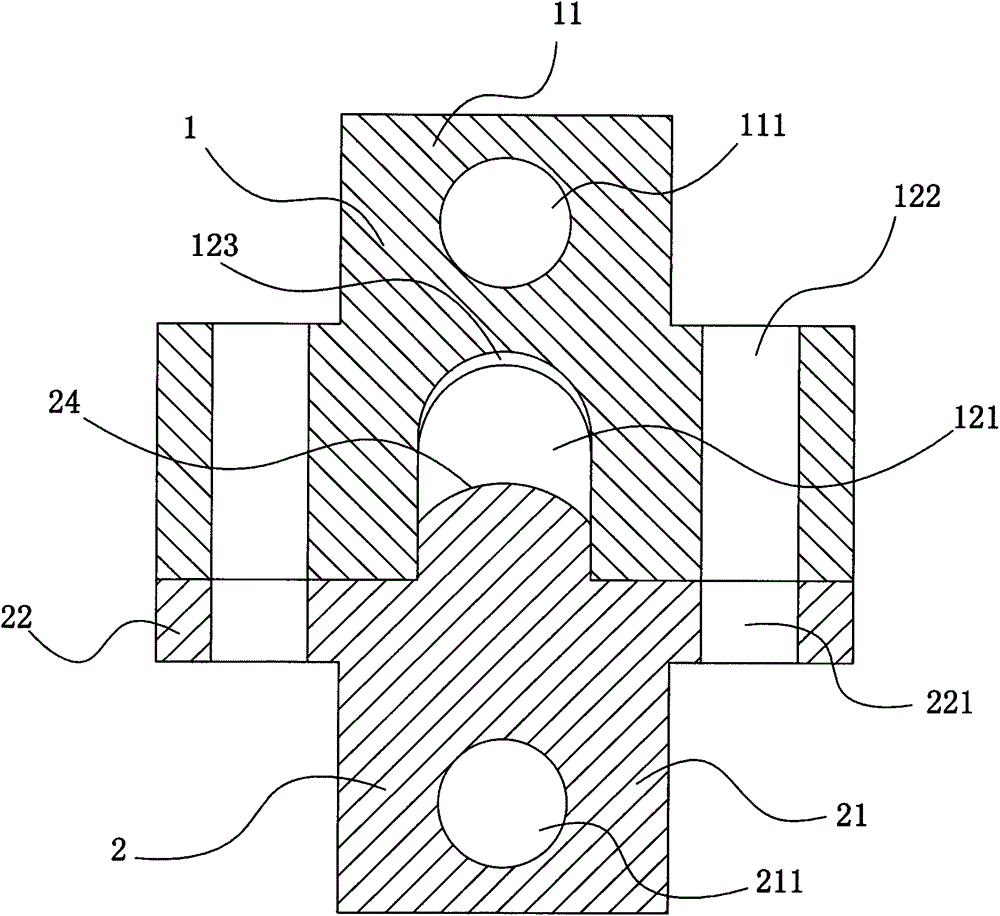

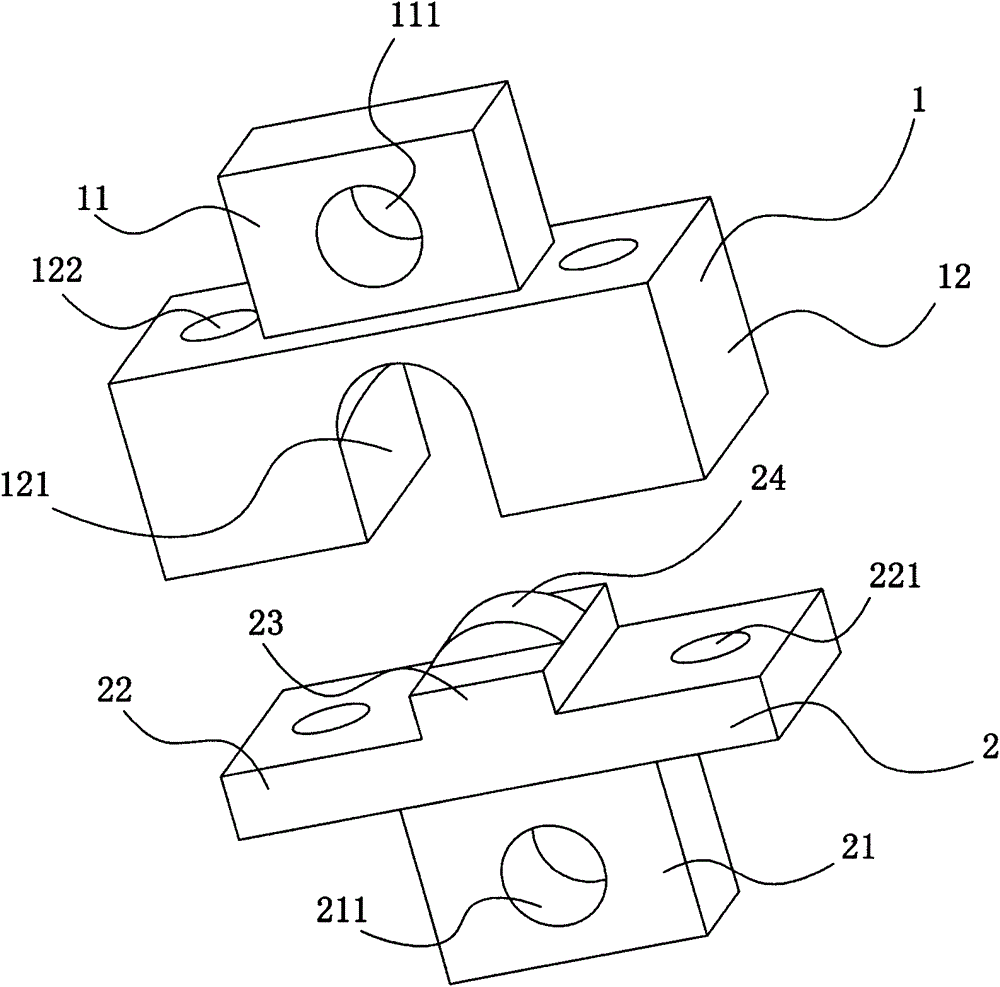

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0013] See figure 1 and figure 2 , the present invention comprises a base 2, the indenter 1 is affixed to the base 2, the base 2 is a T-shaped structure, and includes a horizontal plate 22 with first connecting holes 221 at both ends, and the middle part of the lower surface of the horizontal plate 22 is connected with a first The vertical plate 21 of the fixed through hole 211, the middle part of the upper surface of the horizontal plate 22 has a longitudinal flange 23, the upper surface of the longitudinal flange 23 has a transverse protrusion 24, and the upper surface of the transverse protrusion 24 is an arc-shaped structure; It includes a bottom block 12 with a U-shaped groove 121 matched with the longitudinal flange 23 in the middle. The arc portion of the U-shaped groove 121 has an inner concave portion 123. The second connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com