Multifunction pipe rolling machine

A coiler, multi-functional technology, applied in the field of coiler, can solve problems such as easy to be crushed by the car, difficult to coil, short service life, etc., and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

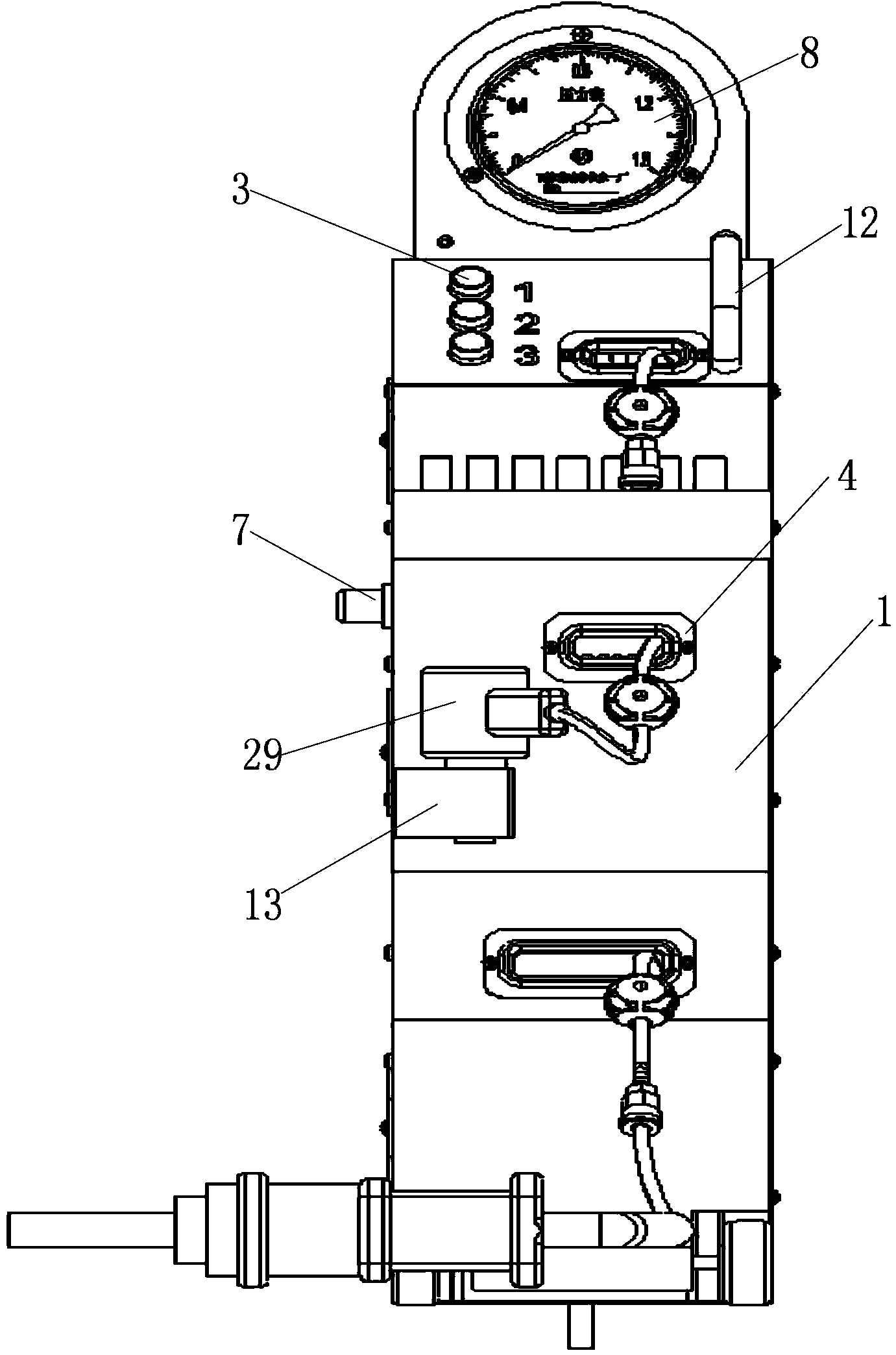

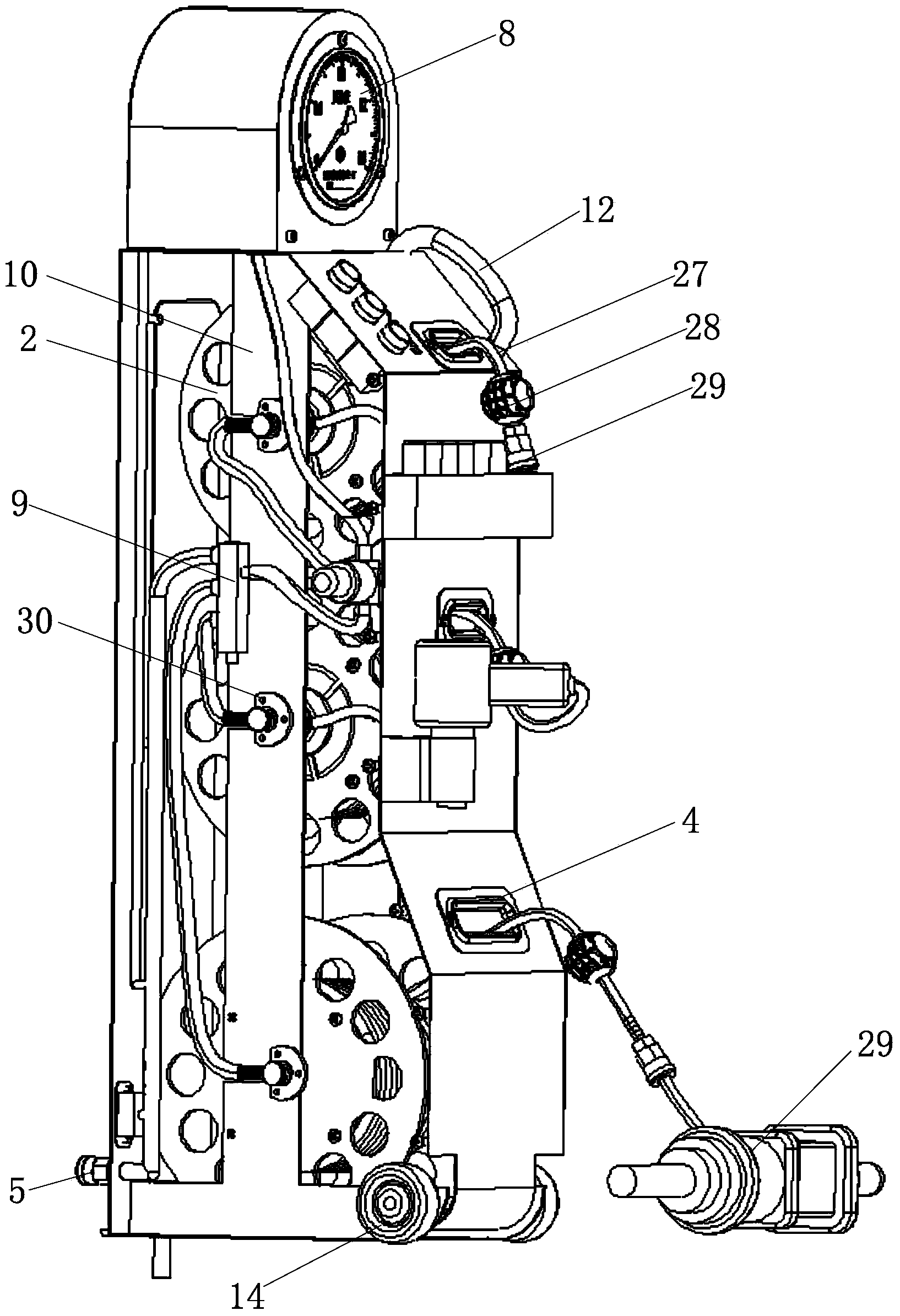

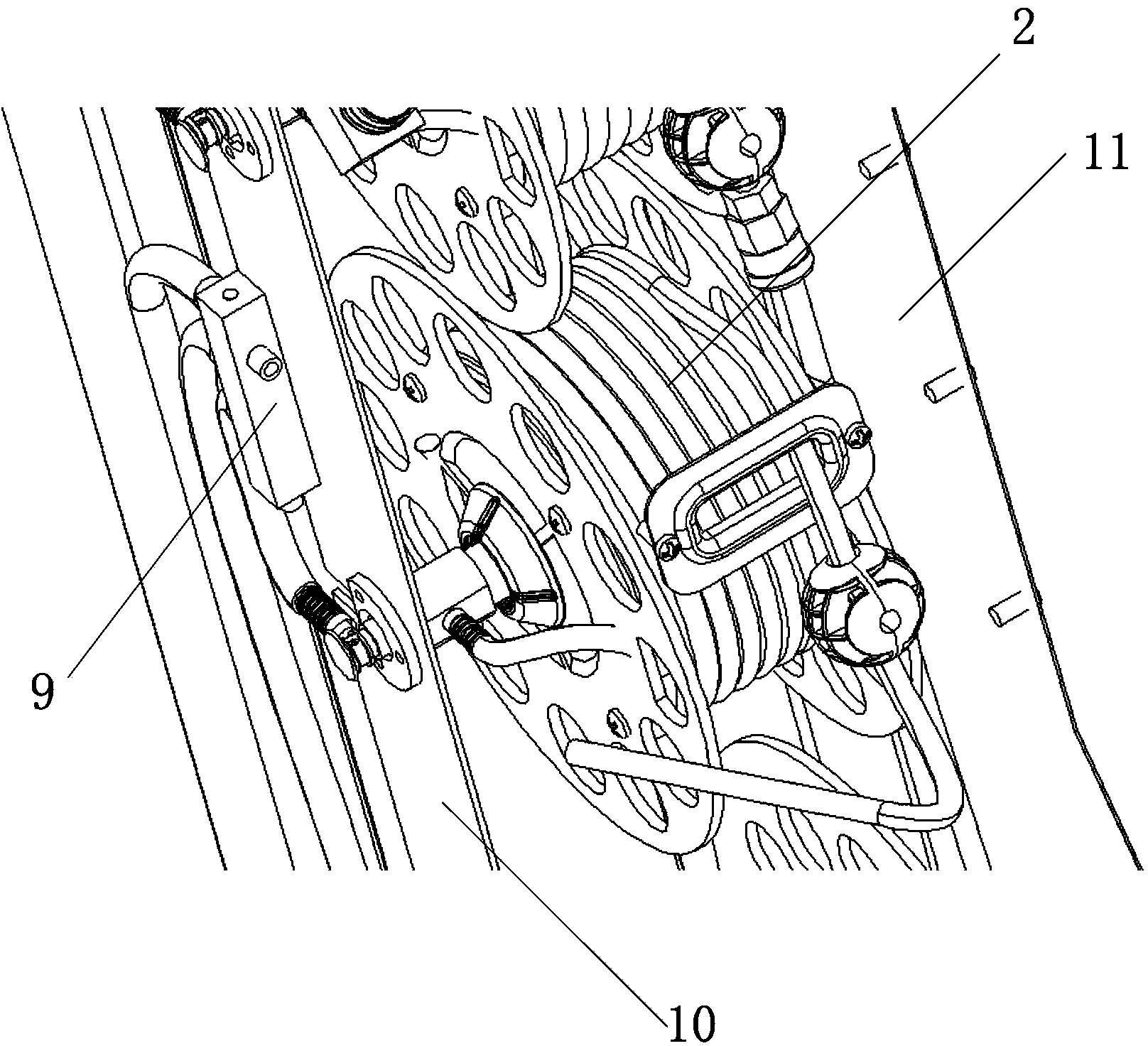

[0042] Such as Figure 1-13 As shown, the present invention provides a multifunctional coiling machine, including a casing 1, a pressure gauge 8 arranged on the casing 1, a plurality of operation buttons 3, a plurality of wear-resistant nozzle plates 4 and an assembly The air port 5, the inside of the casing 1 is provided with a main control circuit board, a transformer group, multiple groups of coiled tube units 2 and one-point multi-air tube joints 9, and the first one for supporting and connecting the multiple groups of coiled tube units 2 The pillar 10 and the second pillar 11; the multiple groups of coiled pipe units 2 are arranged in layers from top to bottom; the total air inlet 5 is connected to a multi-air pipe joint 9 through the first connecting air pipe, and the multiple operation Buttons 3 are connected to the main control circuit board;

[0043] Each set of coiling unit 2 includes a hollow coiling sleeve 20, a first coiling coil 21, a core motor 22, a second coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com