Test system of silicon unit

A test system and silicon unit technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low test efficiency, long waiting time, and large impact, so as to improve test and maintenance efficiency and test environment safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

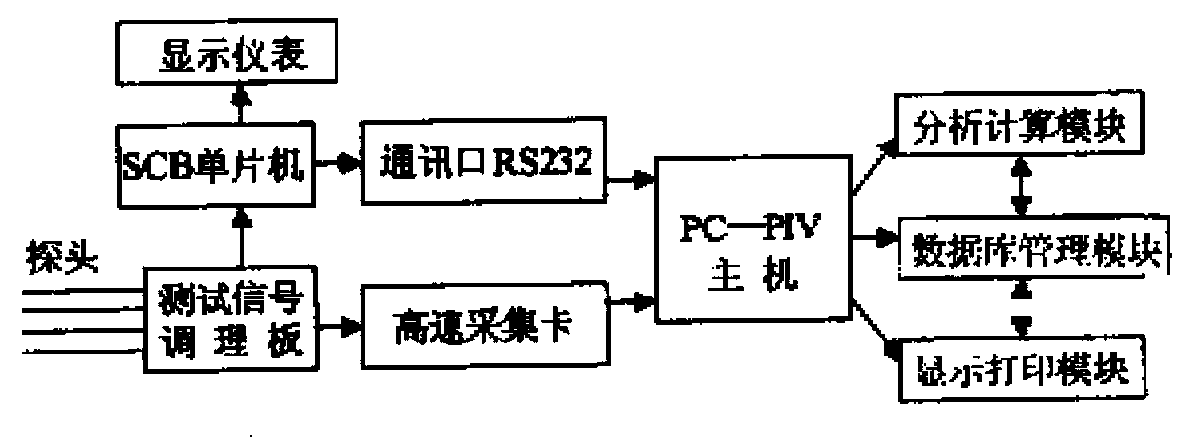

[0009] see figure 1 , a silicon unit test system, including a hardware system and a software system, the hardware system includes a probe, a conditioning board, a channel board and a signal generation board, providing services for obtaining correct test data; the software system is for the collection and processing of test data data management module.

[0010] The data management module manages real-time data and historical data, and the display and printing module provides a good tool for users to fill in the test report, and the curve of the test data provides a visual and intuitive environment for the analysis of the test data.

[0011] The silicon unit test system is composed of its hardware system and software system. Probes, conditioning boards, channel boards, and signal generation boards provide services for obtaining correct test data. Considering the practicability of the system, two sets of relatively independent hardware systems are used for the collection and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com