Battery heating control method and device

A battery heating and battery technology, applied to secondary batteries, battery temperature control, circuits, etc., can solve the problems of inaccurate temperature detection and control, and achieve the effect of direct, accurate and accurate internal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

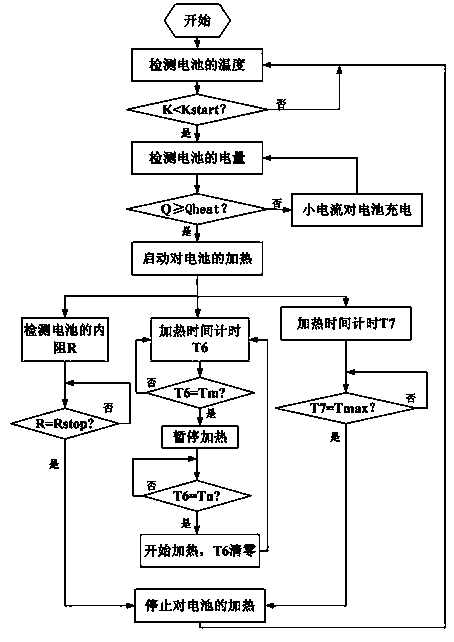

[0038] This embodiment can be divided into three parts, starting heating part, staged heating cycle part and stopping heating part. figure 1 It is a flowchart of a method for controlling battery heating according to an embodiment of the present invention, such as figure 1 As shown in the figure, after “starting” and before “starting the heating of the battery” are the condition judgment parts for starting the heating in this method; after “starting the heating of the battery” and before “stopping the heating of the battery”, both sides The process in the flow chart is the judging part of the stop condition, and the middle cycle is the cycle of the segmented heating process before the heating is stopped.

[0039] The method for controlling battery heating provided in this embodiment is generally divided into two steps: when the conditions for starting heating are met, start heating the battery; and when the conditions for stopping heating are met, stop heating the battery.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com