A method of life prediction for environmental barrier coating EBC

A technology of life prediction and coating, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of long time consumption, high cost of testing equipment and environmental assessment tests, and achieve the effects of low cost, simple and reliable method, and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0036] Specific embodiment 1: the lifetime prediction of BSAS-EBC coating

[0037] Concrete preparation steps are as follows:

[0038] 1. Preparation of silicon carbide bonding layer:

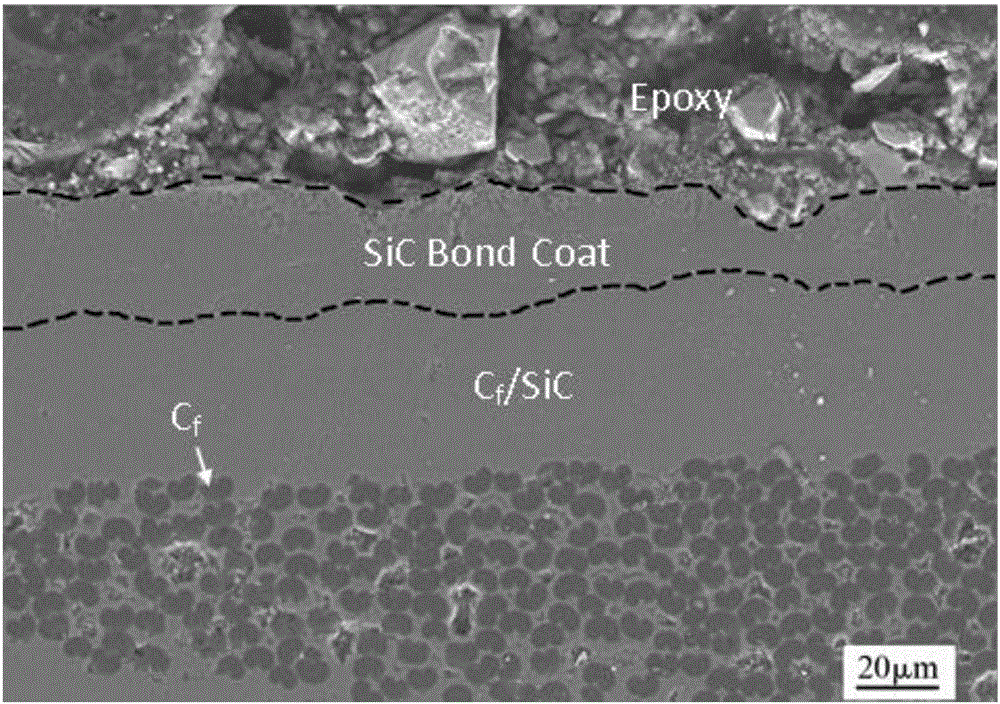

[0039] Selection of continuous carbon fiber reinforced silicon carbide ceramic matrix composites (C f / SiC), the C f / SiC is made into a strip sample with a size of 40×5×3.5mm, which is cleaned by ultrasonic waves. A dense silicon carbide bonding layer was prepared on the surface of the sample by chemical vapor deposition (CVD). Using a scanning electron microscope (SEM), measure the thickness of the bondline, as figure 1 shown. In this embodiment, the adhesive layer has a thickness of 30 μm.

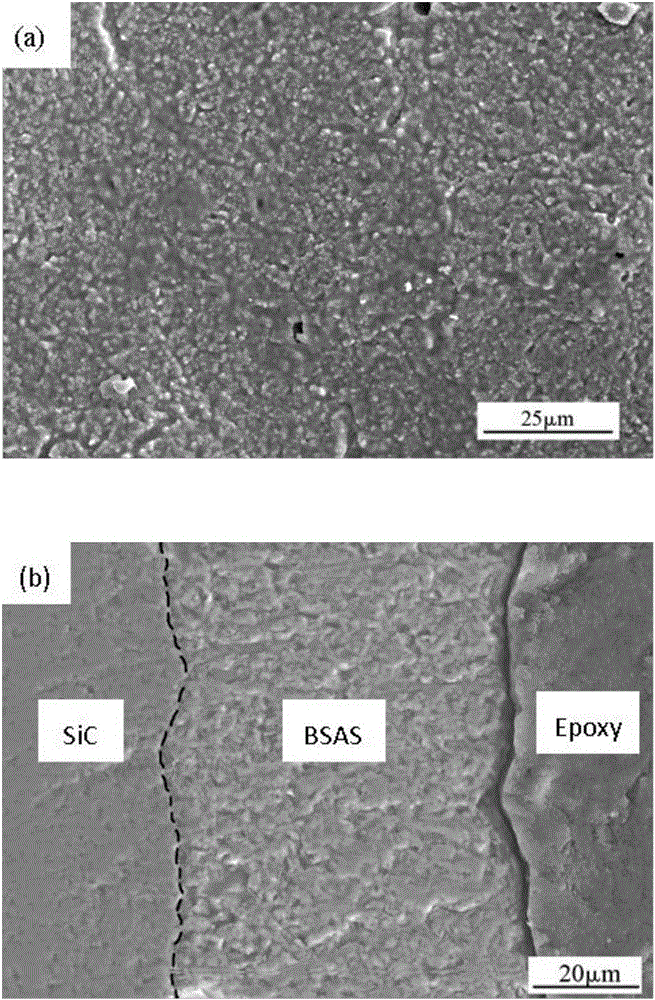

[0040] 2. Preparation of BSAS-EBC coating:

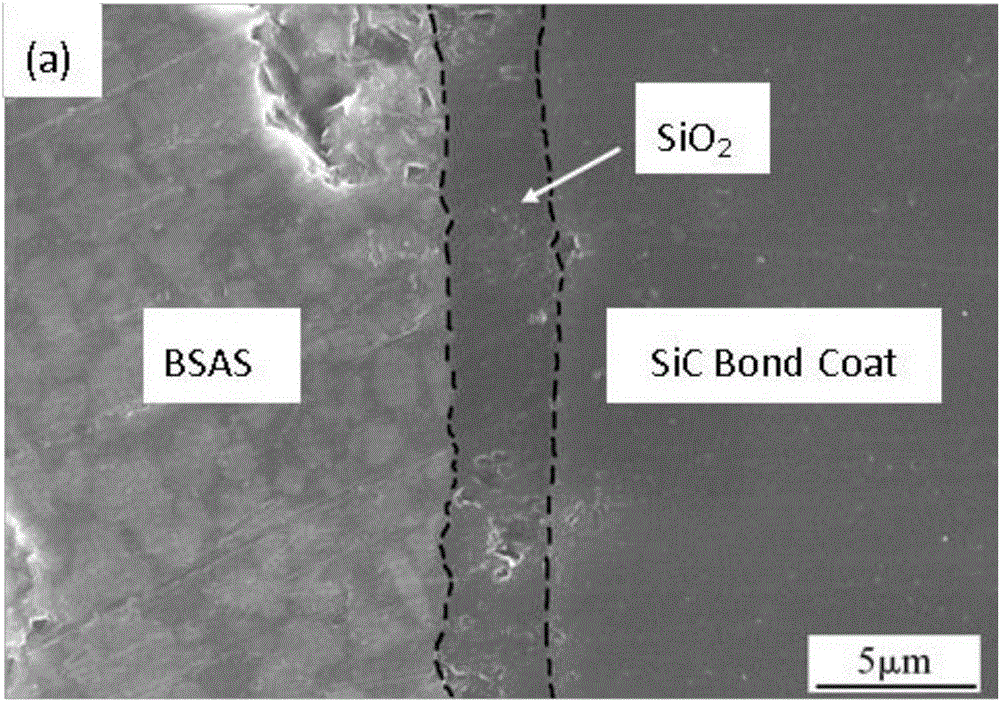

[0041] 1) Add 20wt% of the total weight of polyazide silane to 80% of the total weight of alcohol to prepare a polyazide silane solution, add 45 wt% of the BSAS powder to the polyazide silane solution, and then add the total 5 wt% H 3 BO 3 As a sinte...

Embodiment 2

[0055] Embodiment 2: adopt slurry method to prepare Sc 2 Si 2 o 7 The EBC coating, its preparation process and performance assessment method are the same as in Example 1. In this example, C f / SiC uses silicon carbide (thickness 30μm) as the bonding layer, and its SiO 2 The critical thickness of the layer is 5.5 μm; at the same time, the Sc 2 Si 2 o 7 The coating thickness is 50 μm, the oxidation and corrosion kinetic constant k corresponding to the coating p The value is: k p =0.0541, using the formula (3) to predict the life of this coating in the water and oxygen corrosion environment is 559h. A long-term water-oxygen corrosion assessment was carried out on the sample. After 550 hours of water-oxygen corrosion, the coating failed, which shows that in the water-oxygen corrosion environment, the Sc 2 Si 2 o 7 The whole life of the coating is about 550h. This is very close to the predicted life, indicating that the prediction method is feasible.

Embodiment 3

[0056] Embodiment 3: adopt slurry method to prepare BSAS-Sc 2 Si 2 o 7 The EBC coating, its preparation process and performance assessment method are the same as in Example 1. In this example, C f / SiC uses silicon carbide (thickness 30μm) as the bonding layer, and its SiO 2 The critical thickness of the layer is 5.5 μm; meanwhile, BSAS-Sc 2 Si 2 o 7 The coating thickness is 50 μm, the oxidation and corrosion kinetic constant k corresponding to the coating p The value is: k p =0.0653, using the formula (3) to predict the life of this coating in the water-oxygen corrosion environment is about 463h. A long-term water-oxygen corrosion assessment was carried out on the sample. After 450 hours of water-oxygen corrosion, the coating failed, which shows that the BSAS-Sc in the water-oxygen corrosion environment 2 Si 2 o 7 The whole life of the coating is about 450h. This is very close to the predicted life, indicating that the prediction method is feasible.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com