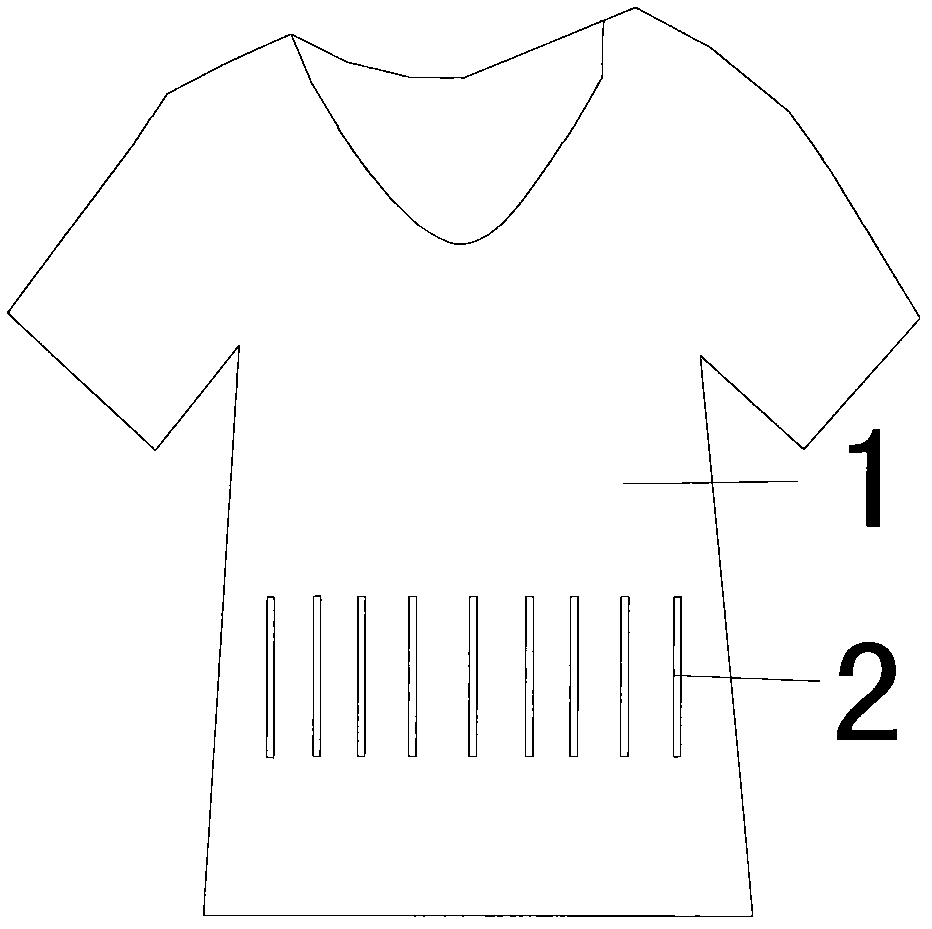

Three-phase braided fabric T-shirt with hollowed-out part

A braided and short-sleeved technology, which is applied in the field of three-phase braided short-sleeved fabrics, can solve the problems of discomfort, poor ventilation performance of short-sleeved sleeves, poor wearing effect, etc., achieve cool and comfortable wearing, improve ventilation performance, increase density and The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] see figure 1 , the present invention relates to a three-phase braided short sleeve with hollows, comprising a short sleeve body 1, the waist of the short sleeve body 1 is provided with several hollows 2, and the hollows 2 are hole hollows or strip hollows, The fabric around the hollow 2 is made of georgette fabric, the short-sleeved body 1 is made of fabric, and the fabric is a three-phase braided fabric interwoven with yarns. 1. Among the left-dipping warp yarns and right-dipping warp yarns, the weaving rule is: a weft thread passes under a left-dipping warp yarn to the next right-dipping warp yarn, and then enters under the next left-dipping warp yarn, and so on. Weaving goes on; And the weft yarn adjacent to said weft yarn passes under a right-leaning warp yarn to the next left-leaning warp yarn, and then enters under the next right-leaning warp yarn, and weaves accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com