Combined type spanner

A combined, wrench technology, applied in the directions of wrenches, manufacturing tools, wrenches, etc., can solve the problems of inability to tighten screws or bolts with wrenches, poor adaptability of screws or bolts, etc., and achieve easy adjustment of the thickness of the bayonet, adjustable thickness, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

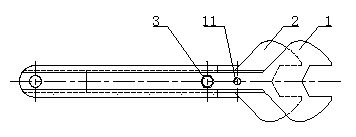

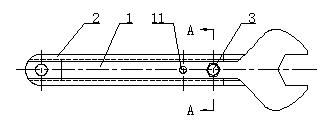

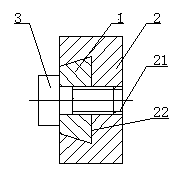

[0009] see Figure 1 to Figure 3 , the present invention includes an adjustable wrench 1 and a fixed wrench 2, the adjustable wrench 1 and the fixed wrench 2 are combined by a screw 3, the adjustable wrench 1 is provided with two positioning holes 11, and the handle of the fixed wrench 2 A threaded hole 21 and a dovetail groove 22 are provided. The part where the adjustable wrench 1 is inserted into the dovetail groove 22 has a cross-sectional shape of a trapezoidal cross section that is compatible with the angle of the dovetail groove 22. The adjustable wrench 1 can be inserted into the dovetail groove of the fixed wrench 2. 22 to slide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com