Cleavable brick having a partial natural section and fabrication method thereof

A manufacturing method and a technology of splitting bricks, which are applied in the direction of manufacturing tools, building structures, ceramic molding machines, etc., can solve the problems of poor consistency, low yield, and unsuitable for large-area laying of exterior wall bricks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

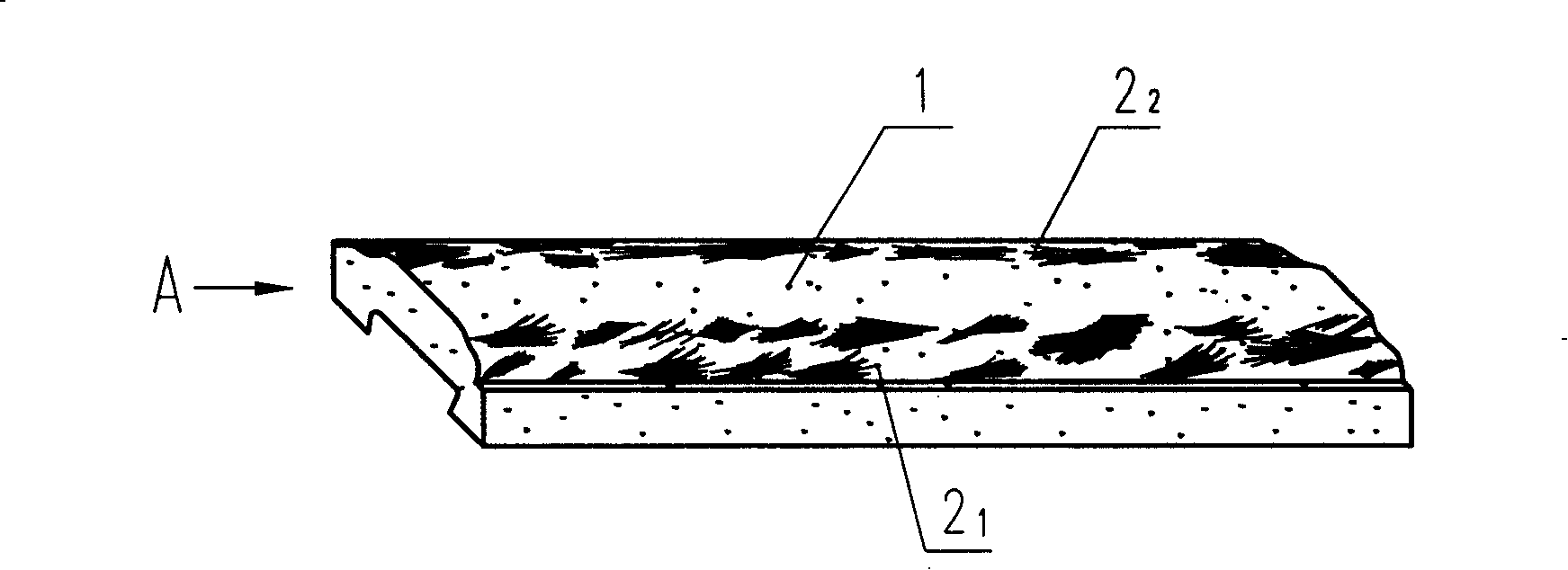

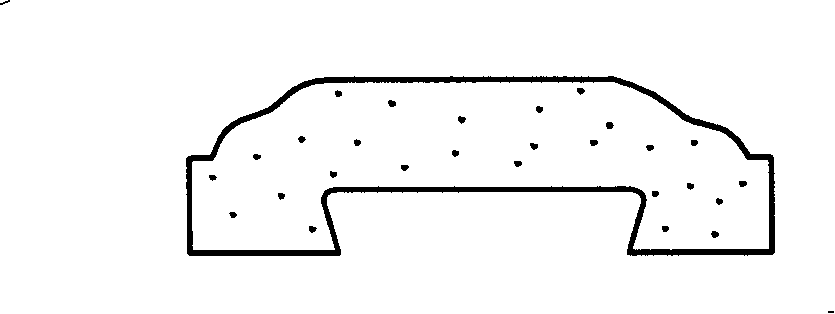

[0025] A pitted split brick with a partly natural section. Such as figure 1 Shown: the decorative surface of the pitted surface splitting brick - that is, the middle part of the upper surface is a flat plane 1, and the two sides of the flat plane 1 on the upper surface have a certain slope with the middle part of the plane 1 and have natural stone Natural section of section pattern 2 1 ,2 2 , the natural section 2 1 ,2 2 It is a natural section formed by mechanical or manual knocking.

[0026] As a change in the embodiment of the present invention, the split brick with part of the natural section can also be an ordinary split brick without sand grains, and the brick can be the same color, or have various stripes or Pattern (including wood grain).

Embodiment 2

[0028] A method for manufacturing a split brick with a partly natural section, the method comprises the following steps:

[0029] a. Material preparation: general ceramic raw materials are used as mud materials, and spiral vacuum extruders are used as special equipment;

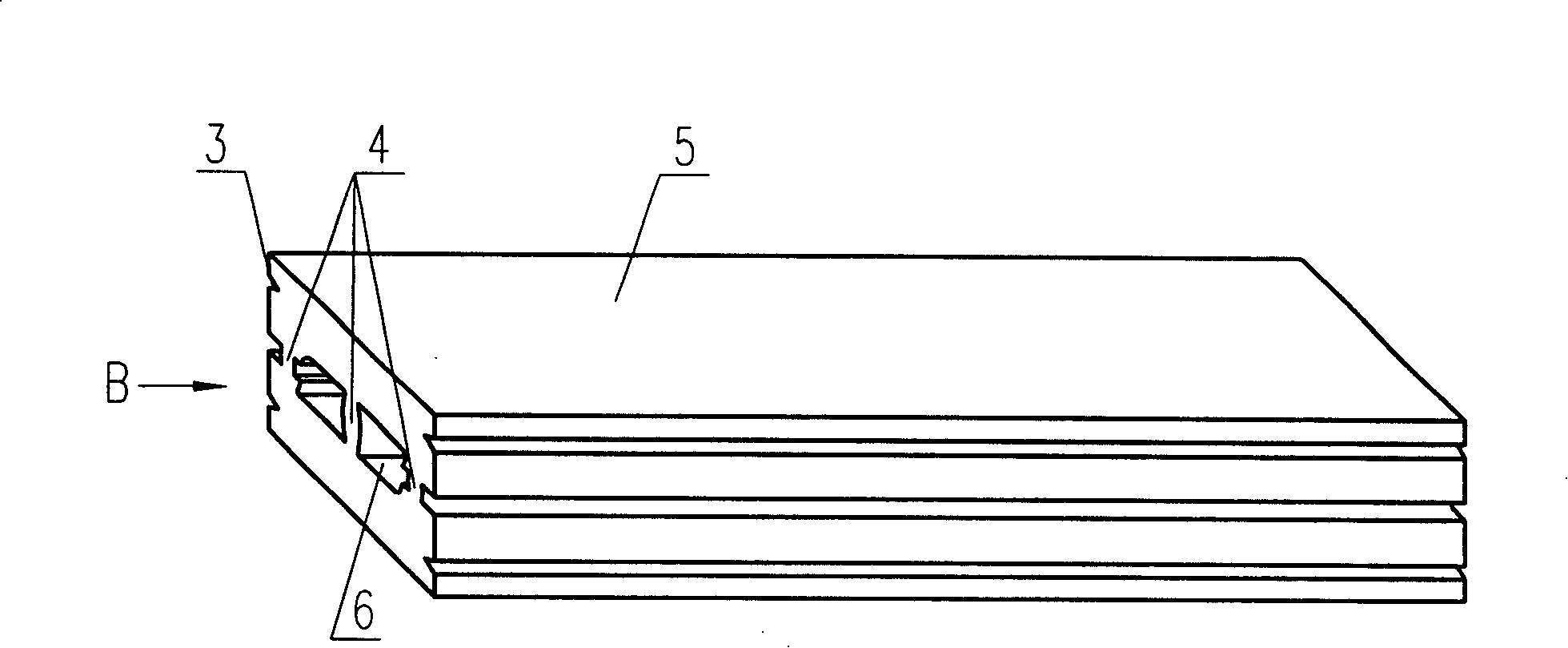

[0030] b. Extruded brick adobe: Extrude the mud material through a spiral vacuum extruder with a conventional splitting brick adobe forming method, and cut it into a cuboid block mud adobe 5 with two bricks. There is a through hole in the middle of the mud adobe 6. There are 1 to 6 ribs 4 connected between two bricks, and a "V"-shaped groove 3 is extruded on both sides of the brick adobe, which is less than 1 / 2 of a single brick body from the decorative surface (see image 3 , Figure 4 );

[0031] c, dry mud: the above-mentioned cuboid block mud with two bricks is dried to moisture content 1~10%;

[0032] d. Manufacture the natural section: place the dry block mud adobe 5 on the plane so that the decorati...

Embodiment 3

[0038] A kind of manufacturing method of splitting brick with partial natural section, its basic steps are the same as embodiment one, the difference is: the described process of manufacturing natural section is by manual method, namely: d, manufacture natural section: dry The blocky mud adobe is placed on the plane, and the outside of the middle of the left and right decorative surfaces of the adobe is knocked off by a knife along the "V" groove by hand, so that the middle part of the decorative surface is flat, and the two sides have a certain slope from the middle and A natural section with a natural stone section pattern.

[0039] As a change in the embodiment of the present invention, the general ceramic raw materials used as mud can be made of ceramic raw materials of the same texture and color, or can be made of ceramic raw materials of the same texture and different colors. The mud with stripes or patterns made by mixing ceramic raw materials can also be the mud made b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com