Printed matter production device

A technology for manufacturing devices and printed matter, applied to printing devices, printing, typewriters, etc., can solve the problems of high initial cost and large installation area, and achieve the effect of low initial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments for carrying out the present invention will be described using the drawings. Furthermore, the following embodiments do not limit the inventions according to the claims, and all combinations of features described in the embodiments are not necessarily essential to the solution means of the invention.

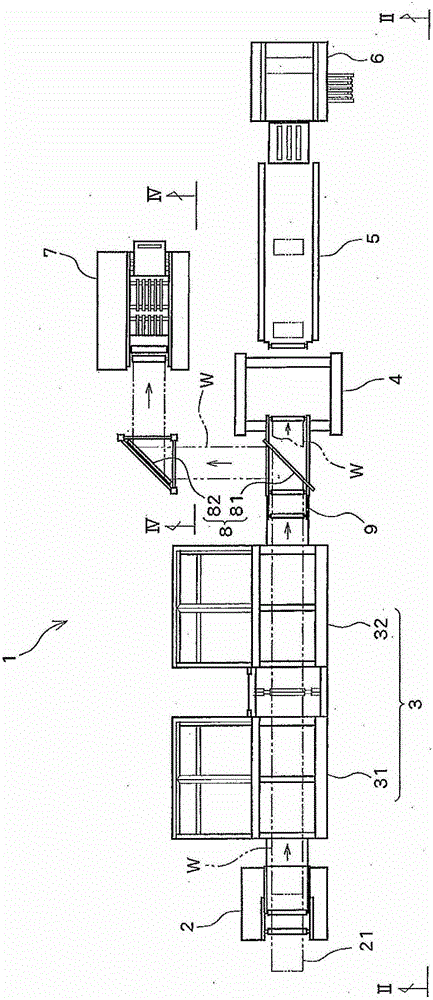

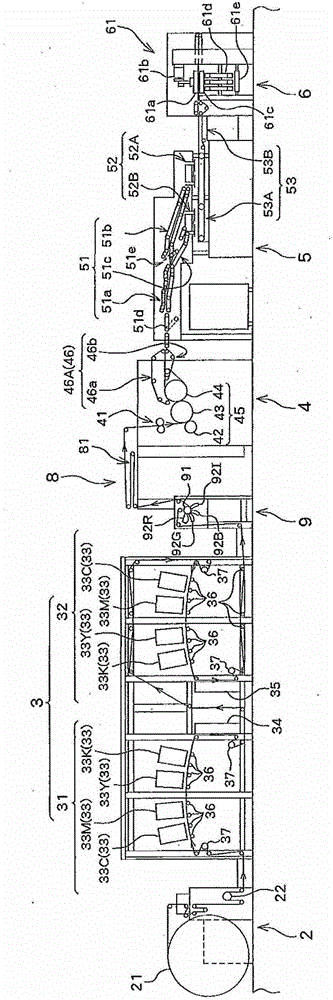

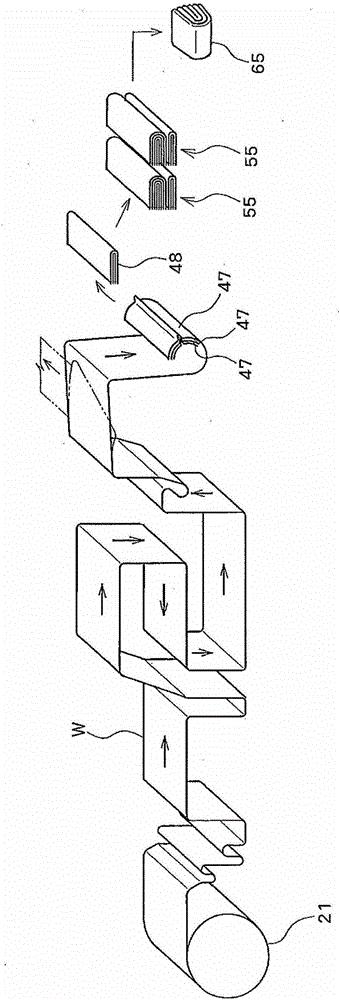

[0043] figure 1 It is a plan view showing the overall configuration of the printed matter creating device of the present embodiment. figure 2 yes figure 1 A schematic view of the printed matter production device shown along the arrow direction of line II-II. image 3 is for paper form to show the use of figure 2 The illustrated printed matter production apparatus is a perspective view of a process of producing a folded sheet-shaped printed matter from continuous paper. Figure 4 yes figure 1 A schematic view of the printed matter production apparatus shown along the arrow direction of line IV-IV. Figure 5 is for paper form to sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com