Pipe wall biofilm growth simulation reactor

A reactor and biofilm technology, applied in the field of simulated reactors, can solve the problems of small reference, small surface area, unfavorable long-term continuous and stable operation of the simulated system, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

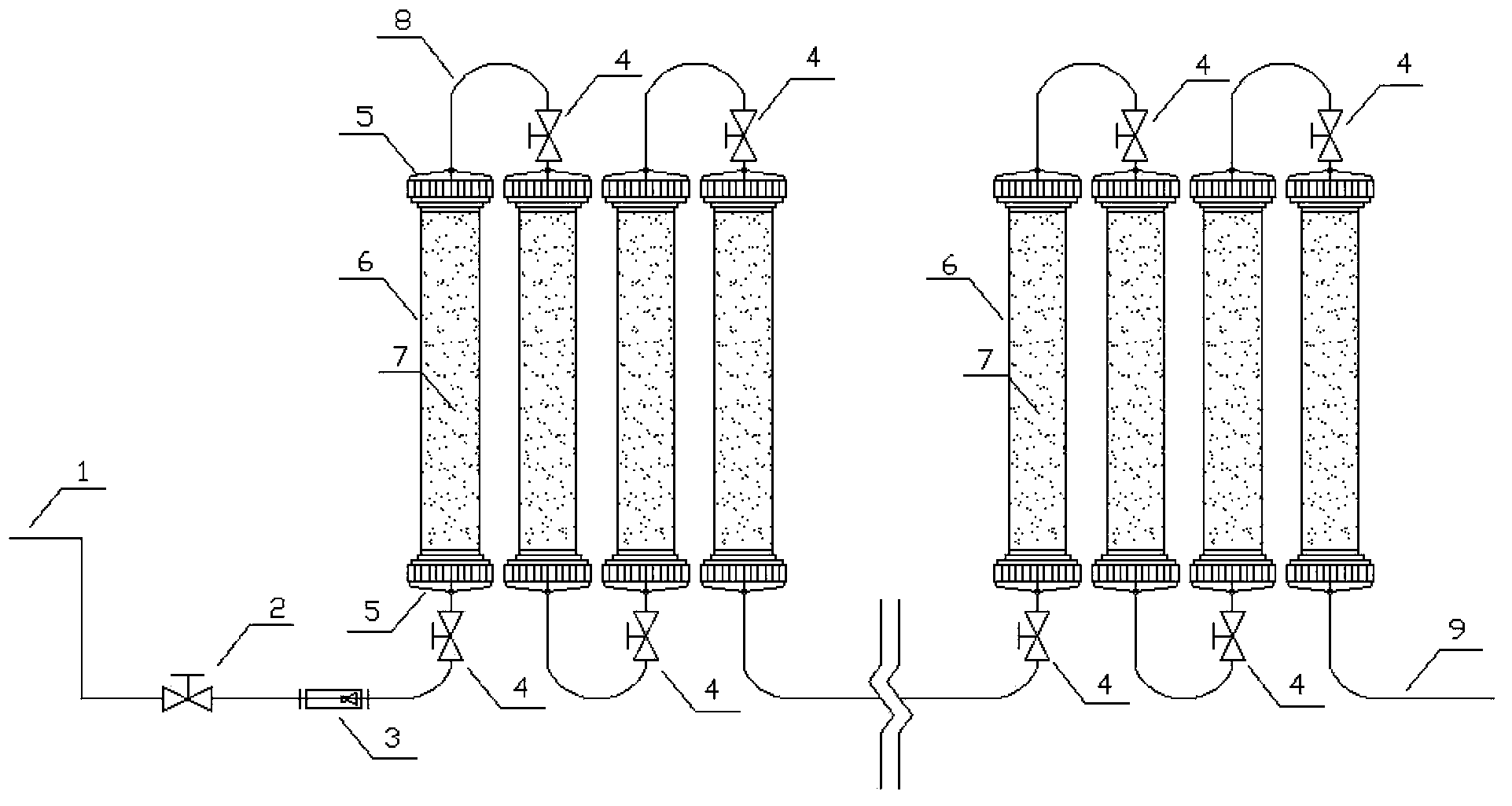

[0026] A kind of pipe wall biofilm growth simulation reactor, the structure is as follows figure 1 Shown, comprise water inlet pipe 1, water outlet pipe 9 and reactor body, between water inlet pipe 1 and water outlet pipe 9, connect a plurality of reactor bodies connected in series, reactor body is made up of water delivery pipe section 6, threaded cap 5 and filler 7 The two ends of the water delivery pipe section 6 are provided with detachable threaded ports, and the threaded caps 5 are connected through the threaded ports, and the filler 7 is arranged inside the water delivery pipe section 6;

[0027] Water enters from the water inlet pipe 1, penetrates each reactor body in turn, flows out from the water outlet pipe 9, takes out the filler 7 in the water delivery pipe section 6, collects the biofilm on the filler 7, and collects water samples at the outlet pipe 9 for analysis , the simulated pipeline is ideally a plug-flow reactor, and the hydraulic and water quality conditi...

Embodiment 2

[0035] A kind of pipe wall biofilm growth simulation reactor, the structure is as follows figure 1 shown. The water inlet pipe 1 is connected to the water tap, and the water inlet flow regulating valve 2 and the flow meter 3 are installed on the water inlet pipe. The water inlet pipe is connected with the water delivery pipe section 6 through the threaded cap 5, and a water inlet valve 4 is installed at the water inlet end of the pipe section. The inside of the water delivery pipe section 6 is filled with a filler 7, and the other end is tightly sealed by a threaded cap 5. Two adjacent threaded caps 5 are connected by connecting elbow 8 and can be made into one. Then connect the next pipe section by the threaded cap 5, and the inside of the pipe section is also loaded with the same amount of plastic packing, and so on to assemble. The last section of the pipe section is connected with the water outlet pipe 9 through the threaded cap 5, and the water outlet pipe 9 can be int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com