A Hard Lever Shift System

A technology of hard rods and pull rods, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem of affecting the driving comfort and reliability of the vehicle, gear disengagement, shifting handle vibration and shifting, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

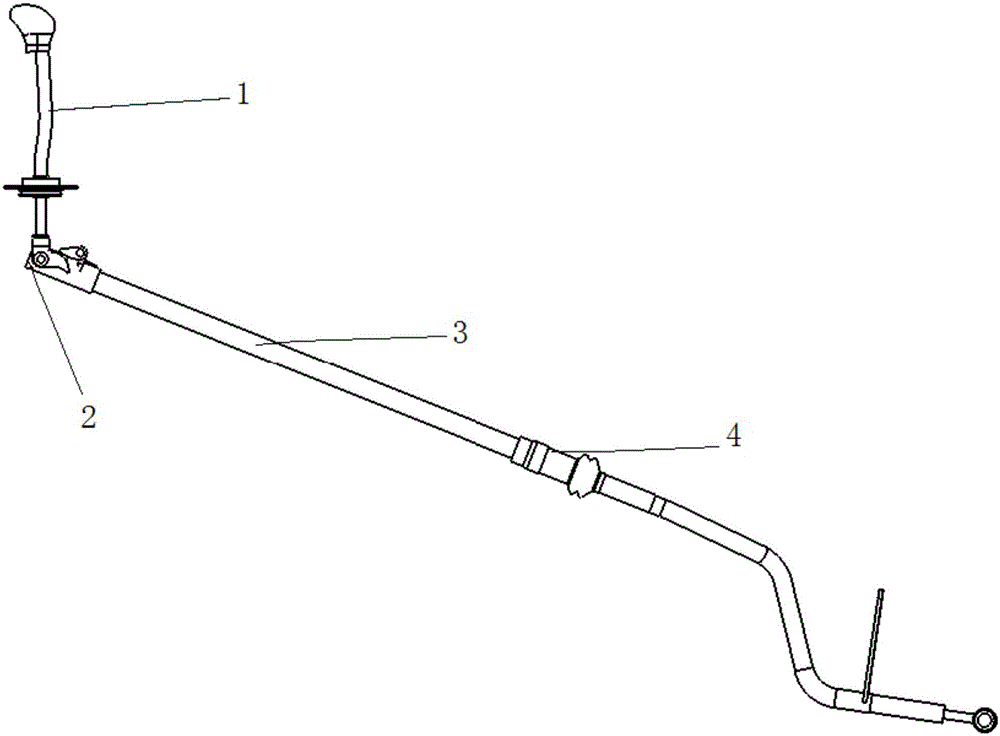

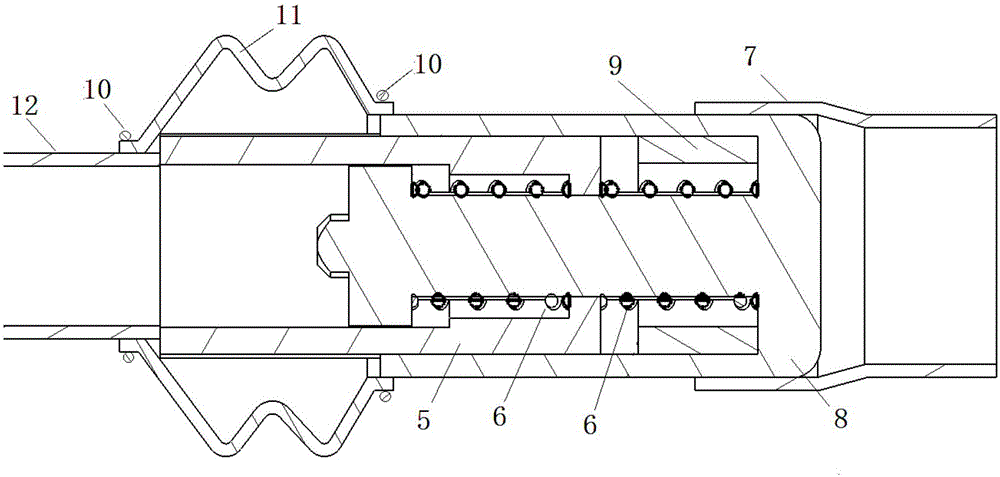

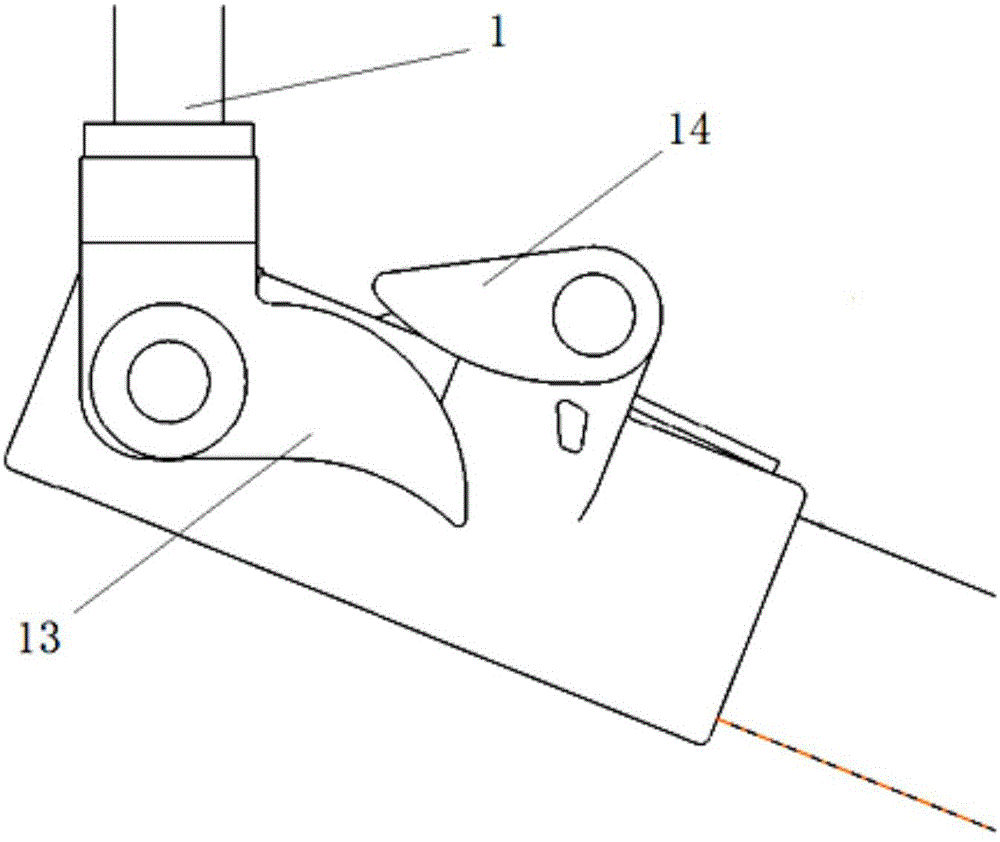

[0018] like Figure 1 to Figure 3 As shown, the present invention provides a hard lever shift system, including a shift manipulation assembly 1 and a shift rod assembly 3 . The shift rod assembly 3 is divided into a front gear shift rod 7 and a rear gear shift rod 12, and the front gear shift rod 7 and the rear gear shift rod 12 are connected by a buffer device 4. The buffer device 4 can absorb the impact of the shift rod assembly 3 during driving, reducing the probability of the transmission being out of gear.

[0019] The buffer device 4 includes a slider sleeve 8 installed at the end of the front gear shift rod 7 and a slider 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com