Gear dropping and skipping prevention single pole shifting rigid operating mechanism

A technology of gear selection and hard control, which is applied in the field of traditional automotive systems, can solve the problems of poor adjustment adaptability of the control system in the layout space, and achieve the effect of avoiding severe vibration or even out of gear, improving adaptability, and small layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

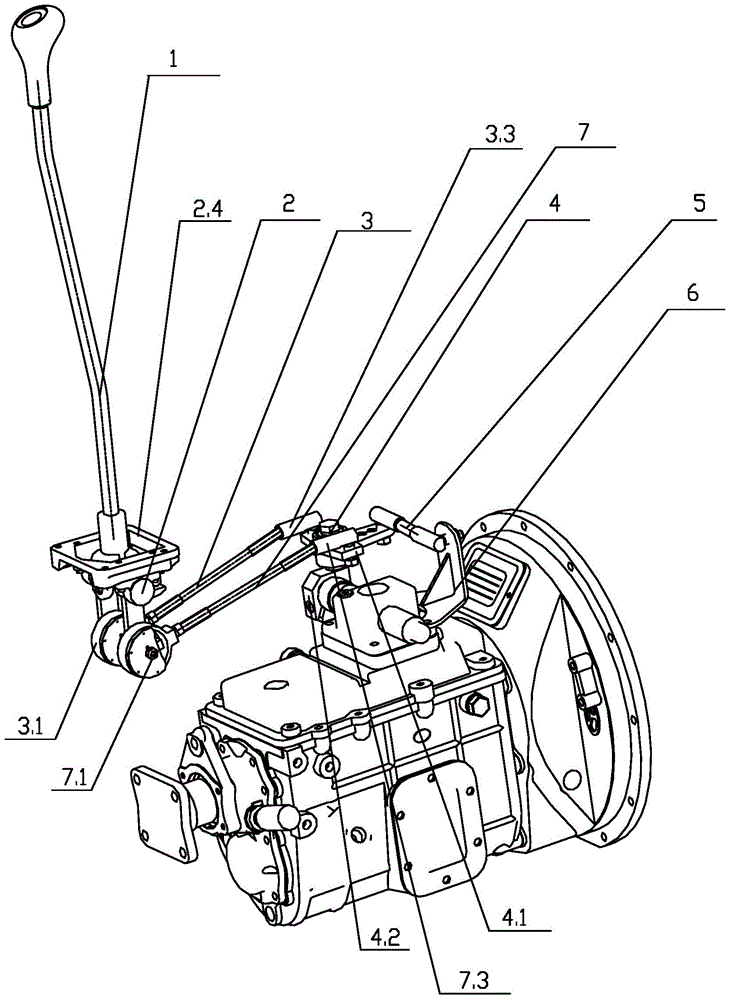

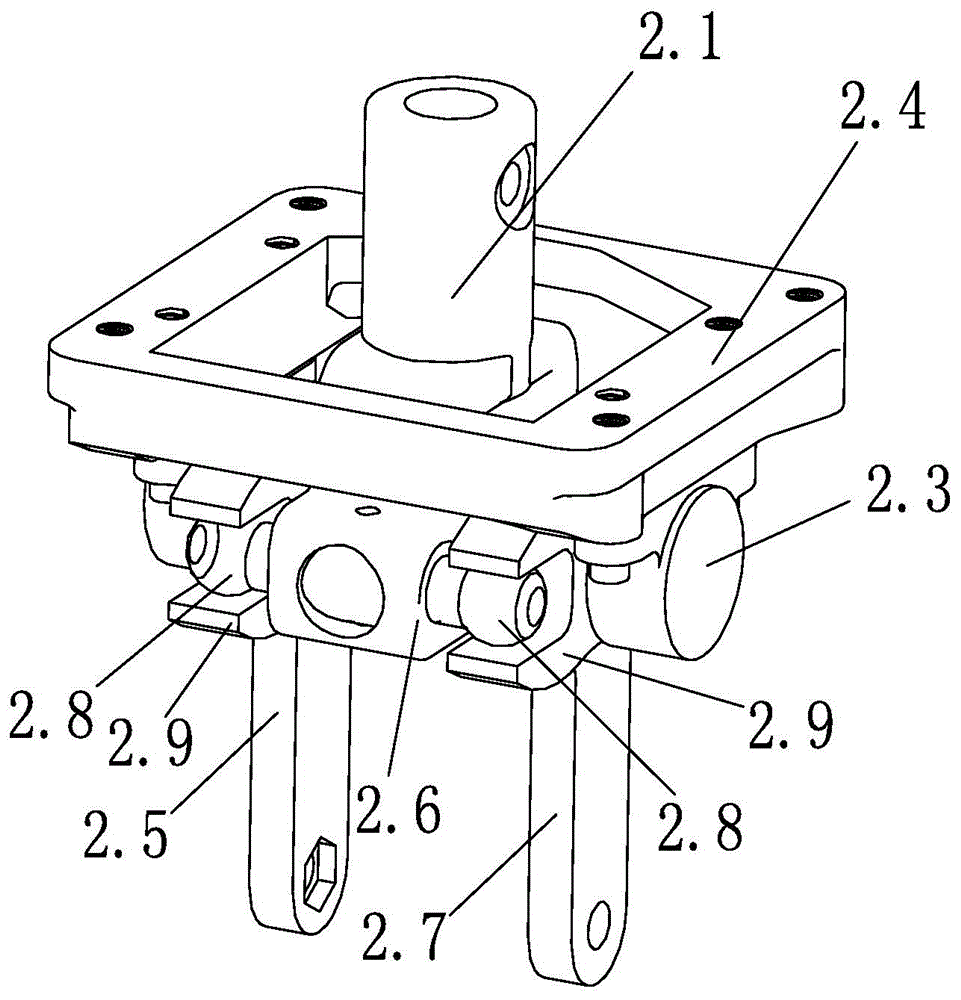

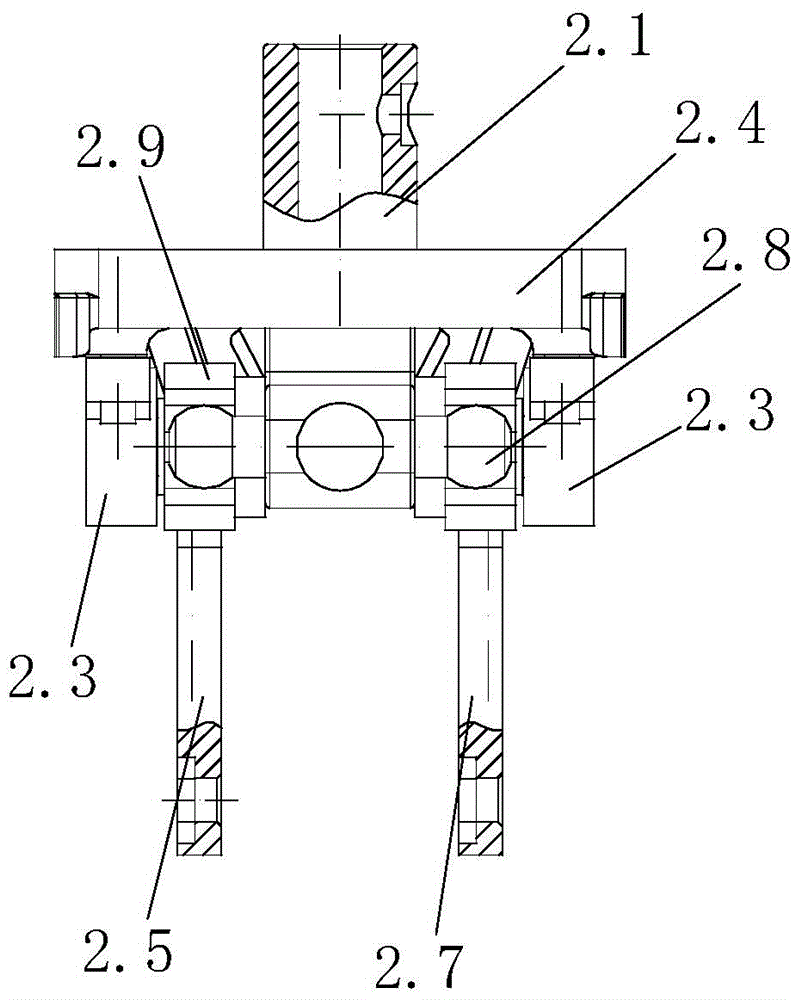

[0040] Such as Figure 1-15 The shown anti-off gear jump gear single-lever selection and shift hard control mechanism includes a joystick 1, a control mechanism 2, a conversion mechanism 4, a positioning rod mechanism 5, a left linkage mechanism 3, a right linkage mechanism 7, The positioning rod bracket 6 fixed on the gearbox housing;

[0041] Above-mentioned operating mechanism 2 is used for converting the motion of joystick 1 into the motion of left side link mechanism 3 and right side link mechanism 7;

[0042] The above-mentioned conversion mechanism 4 is used to convert the movement of the operating mechanism 2 into the gear selection action inside the gearbox;

[0043] The above-mentioned left link mechanism 3 and right link mechanism 7 are used to connect the operating mechanism 2 and the conversion mechanism 4, and reduce the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com