Fluorine-containing copolymer composition and its production method

A manufacturing method and copolymer technology, applied in the direction of coating, etc., can solve problems such as color tone change, and achieve the effect of haze suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

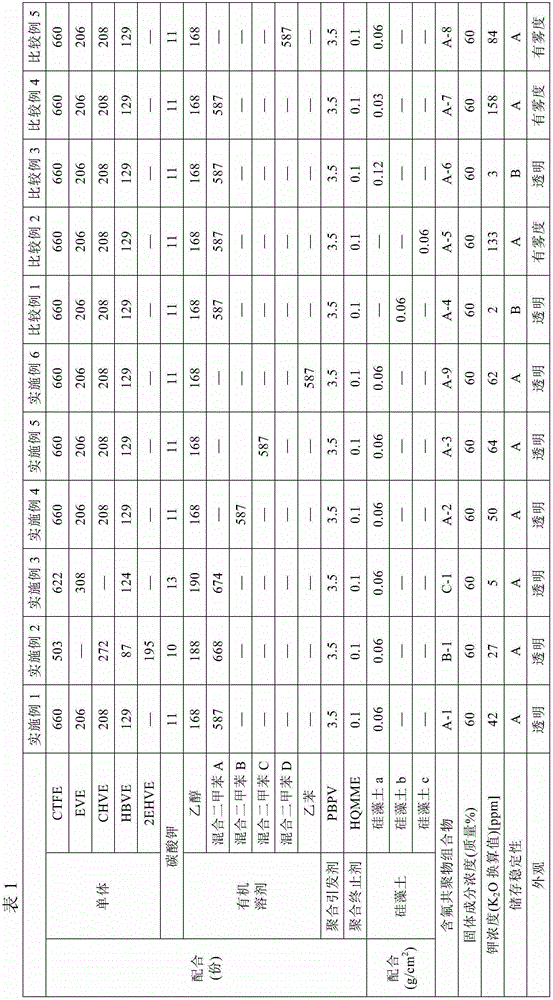

Examples

Embodiment 1

[0182] 587 g of mixed xylene A, 168 g of ethanol, 206 g of ethyl vinyl ether (EVE), 4-hydroxybutyl vinyl ether (HBVE) 129 g, 208 g of cyclohexyl vinyl ether (CHVE), 11 g of potassium carbonate, and 3.5 g of t-butyl peroxy tert-butyl valerate (PBPV), and the dissolved oxygen in the solution was removed by pressurizing with nitrogen, purging, and degassing.

[0183] Next, 660 g of chlorotrifluoroethylene (CTFE) was introduced, the temperature was gradually raised, and the reaction was continued while maintaining the temperature at 65°C. After 12 hours, the reactor was water-cooled to terminate the reaction. After cooling the reaction solution (the solution of the fluorinated copolymer (A)) to room temperature, unreacted monomers were purged, and the reactor was opened.

[0184] The resulting reaction solution (the solution of the fluorine-containing copolymer (A)) is transferred to a pressure filter equipped with No. 63 filter paper for viscous liquid, and after filtering (pre-...

Embodiment 2

[0190] 668 g of mixed xylene A prepared above, 188 g of ethanol, 195 g of 2-ethylhexyl vinyl ether (2EHVE), 4-hydroxybutyl vinyl ether (HBVE) 87g, cyclohexyl vinyl ether (CHVE) 272g, potassium carbonate 10g and tert-butyl peroxy tert-butyl valerate (PBPV) 3.5g, remove the dissolved in the solution by pressurizing, purging and degassing with nitrogen. oxygen.

[0191] Next, 503 g of chlorotrifluoroethylene (CTFE) was introduced, the temperature was gradually raised, and the reaction was continued while maintaining the temperature at 65°C. After 12 hours, the reactor was cooled with water to stop the reaction. After cooling the reaction solution (the solution of the fluorinated copolymer (A)) to room temperature, unreacted monomers were purged, and the reactor was opened.

[0192] The resulting reaction solution (the solution of the fluorine-containing copolymer (A)) is transferred to a pressure filter equipped with No. 63 filter paper for viscous liquid, and after filtering (...

Embodiment 3

[0198] 674 g of mixed xylene A, 190 g of ethanol, 308 g of ethyl vinyl ether (EVE), 4-hydroxybutyl vinyl ether (HBVE) 124 g, 13 g of potassium carbonate, and 3.5 g of t-butyl peroxy tert-butyl valerate (PBPV), and the dissolved oxygen in the solution was removed by pressurizing with nitrogen, purging, and degassing.

[0199] Next, 622 g of chlorotrifluoroethylene (CTFE) was introduced, the temperature was gradually raised, and the reaction was continued while maintaining the temperature at 65°C. After 12 hours, the reactor was cooled with water to stop the reaction. After cooling the reaction solution (the solution of the fluorinated copolymer (A)) to room temperature, unreacted monomers were purged, and the reactor was opened.

[0200] The resulting reaction solution (the solution of the fluorine-containing copolymer (A)) is transferred to a pressure filter equipped with No. 63 filter paper for viscous liquid, and after filtering (pre-filtering) potassium carbonate under a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com