Automatic feeding continuous die of basin stand

An automatic material feeding and mold technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor cost, large equipment loss, and many processes, and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

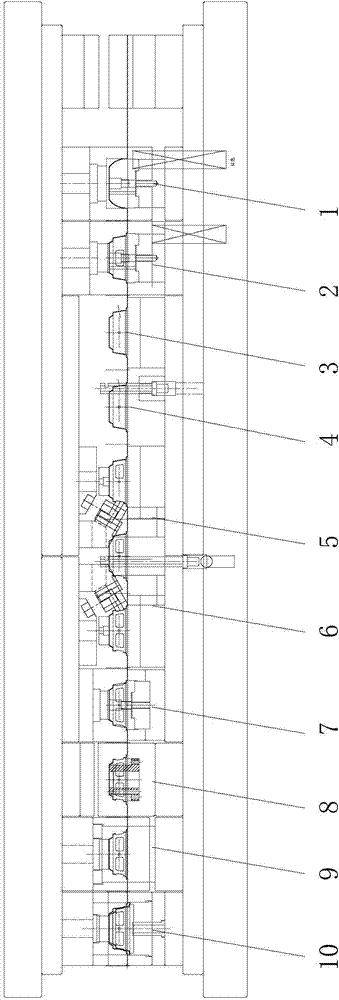

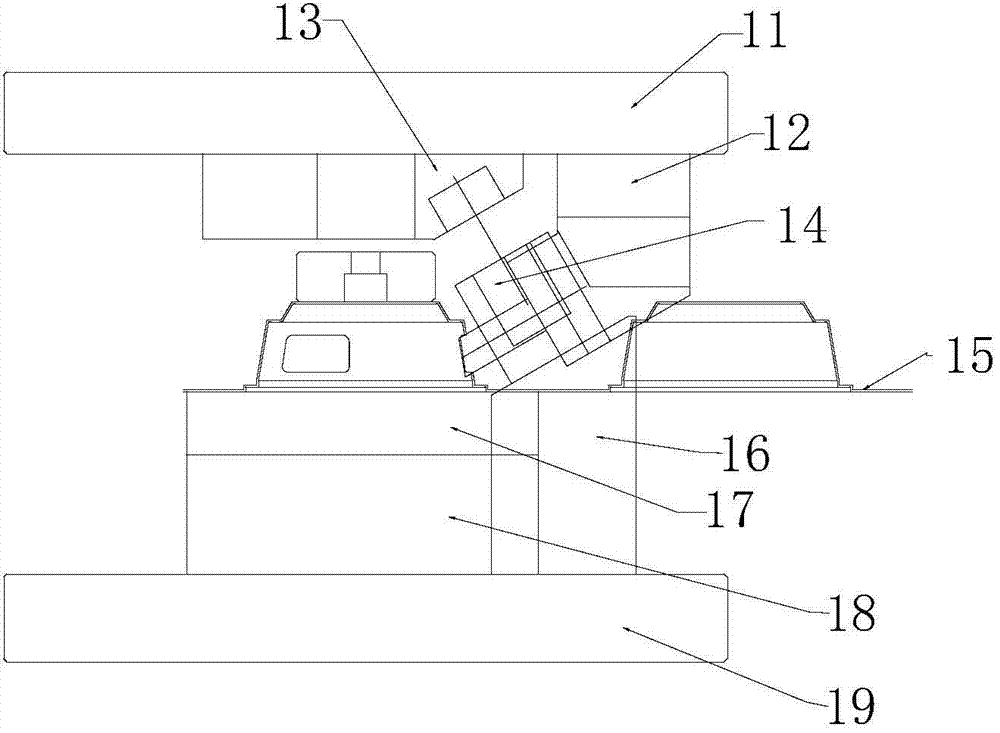

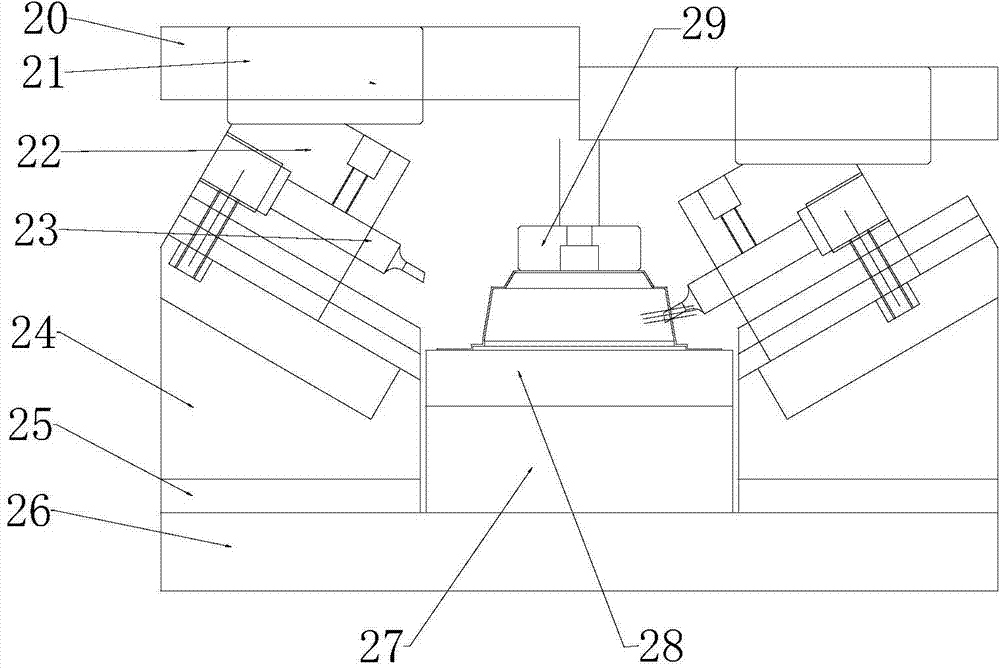

[0019] refer to figure 1 As shown, the invention provides a continuous mold for automatic feeding of the basin frame, which includes the first to tenth stations, and the first to tenth stations are installed in the punching die 1 and the drawing die successively. 2. The first shaping mold 3, the ear hole punching mold 4, the first stamping mold 5, the second stamping mold 6, the second shaping mold 7, the punching mold 8, the trimming mold 9 and the edge returning mold 10, and the molds in the first to tenth stations have the same height when the continuous molds are closed.

[0020] Wherein, the strip 15 can advance through the automatic feeder, and when reaching the first station, the punching mold 1 is closed to punch the groove, at this moment, the slide block on the machine platform of the continuous mold rises, the punching mold 1 open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com