Die for Slitting and Punching Lamination Forming for Hinged Stator

A forming mold, hinged technology, applied in the field of motor stator manufacturing and motor manufacturing, to achieve the effect of convenient opening or closing action, simple structure of punch telescopic mechanism, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

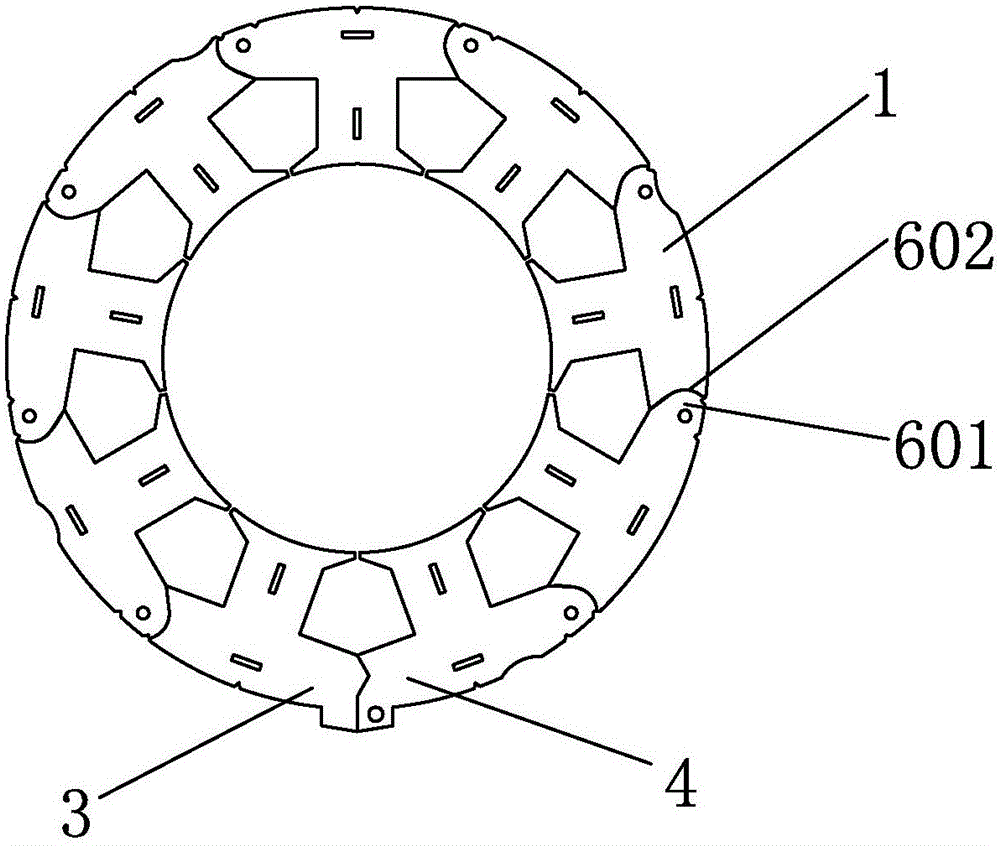

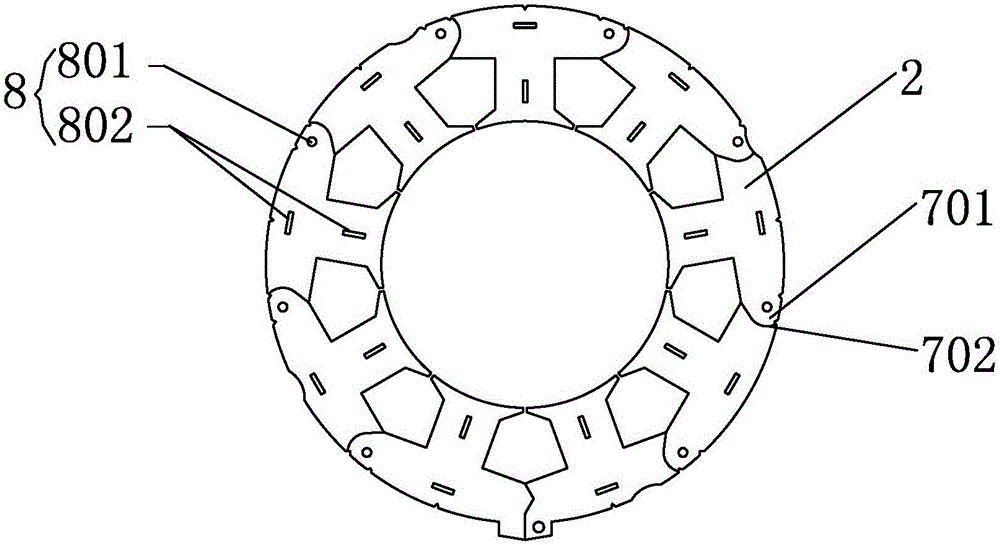

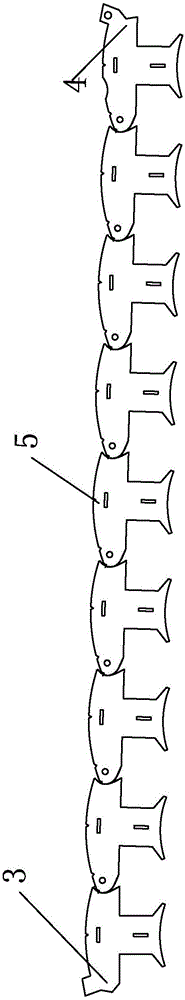

[0029] See Figure 1 to Figure 5 A hinged stator is shown, which includes: a main body 5 composed of several fan-shaped blocks suitable for hinged head to tail sequentially, and a first fan-shaped sub-block 3 and a tail fan-shaped sub-block 4 hinged at both ends of the main body , each fan-shaped block is composed of several left-handed fan-shaped sub-blocks 101 and right-handed fan-shaped sub-blocks 201 alternately stacked up and down. When the first fan-shaped sub-block 3 is connected to the outer end of the tail fan-shaped sub-block 4, the The hinged stator is a closed loop; the joints at the first and last ends of the fan-shaped block are respectively formed by the joints of the corresponding left-handed fan-shaped sub-block 101 and right-handed fan-shaped sub-block 201; the left-handed and right-handed fan-shaped sub-blocks The blocks are respectively formed by superimposing corresponding number of left-handed fan-shaped punches 1 and right-handed fan-shaped punches 2; ...

Embodiment 2

[0057] See Figure 1 to Figure 11 As shown, the manufacturing method of the hinged stator based on the first embodiment, the die process involved in the manufacturing method includes:

[0058] Stamping process S001: Punching and guiding the guiding nail or guiding pin;

[0059] Die stamping process S002: Punching the shape process gap;

[0060] Stamping process S003: groove shape;

[0061] Stamping process S004: vacancy;

[0062] Stamping process S005: punching the arc-shaped cutout 602 of the left hinge 601;

[0063] Stamping process S006: leveling;

[0064] Stamping process S007: punching the arc-shaped cutout 702 of the right hinge 701;

[0065] Stamping process S008: leveling;

[0066] Stamping process S009: vacancy;

[0067] Stamping process S010: measurement;

[0068] Stamping process S011: punching the inner hole;

[0069] Stamping process S012: Punching and riveting points;

[0070] Stamping process S013: vacancy;

[0071]Stamping...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap