Novel hot mill pressing hydraulic cylinder and use method thereof

A technology of hydraulic cylinder and hot rolling mill, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of uncompact mechanism, waste of materials, and the hydraulic cylinder occupies a large space for the height of the rolling mill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

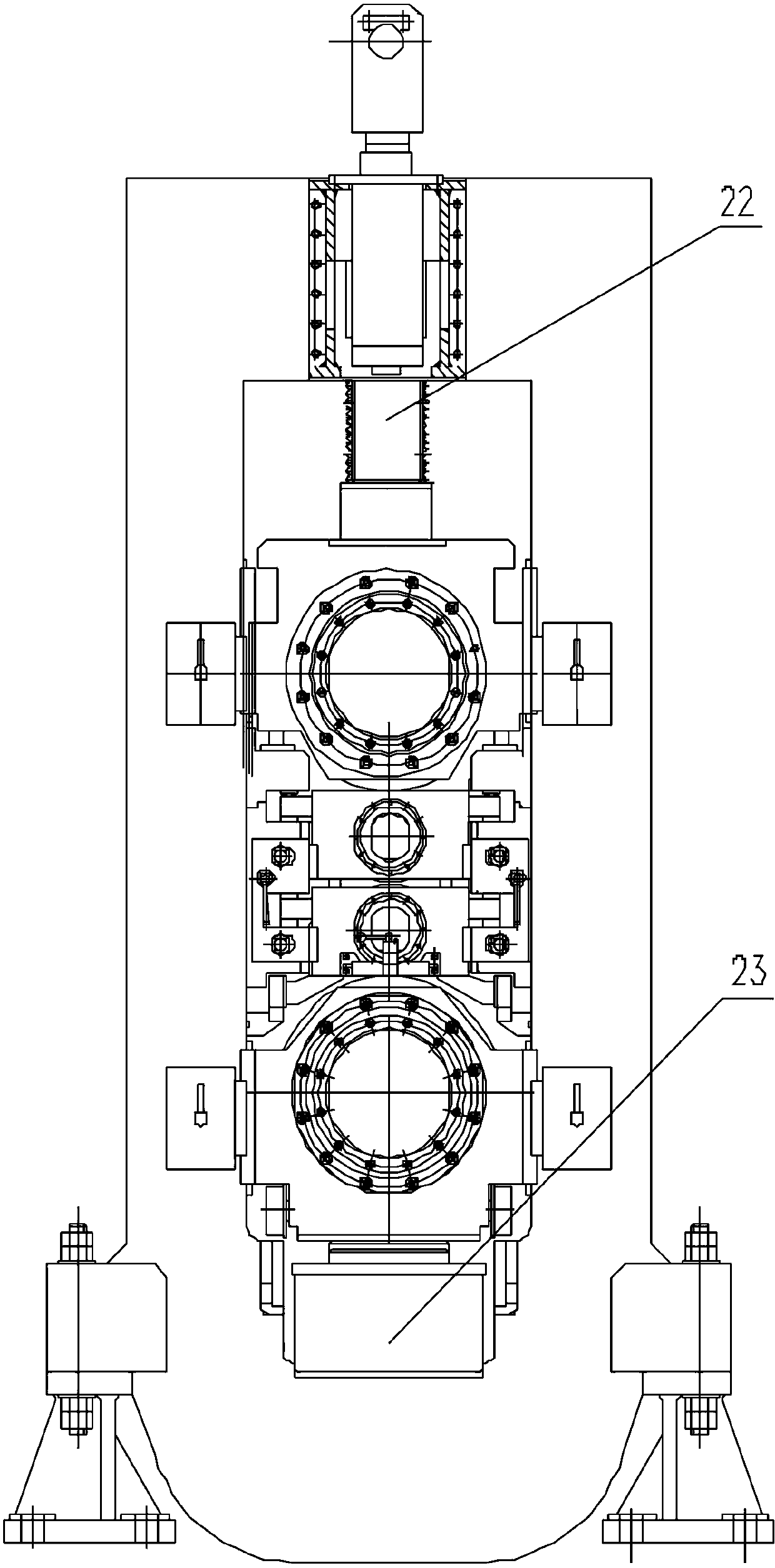

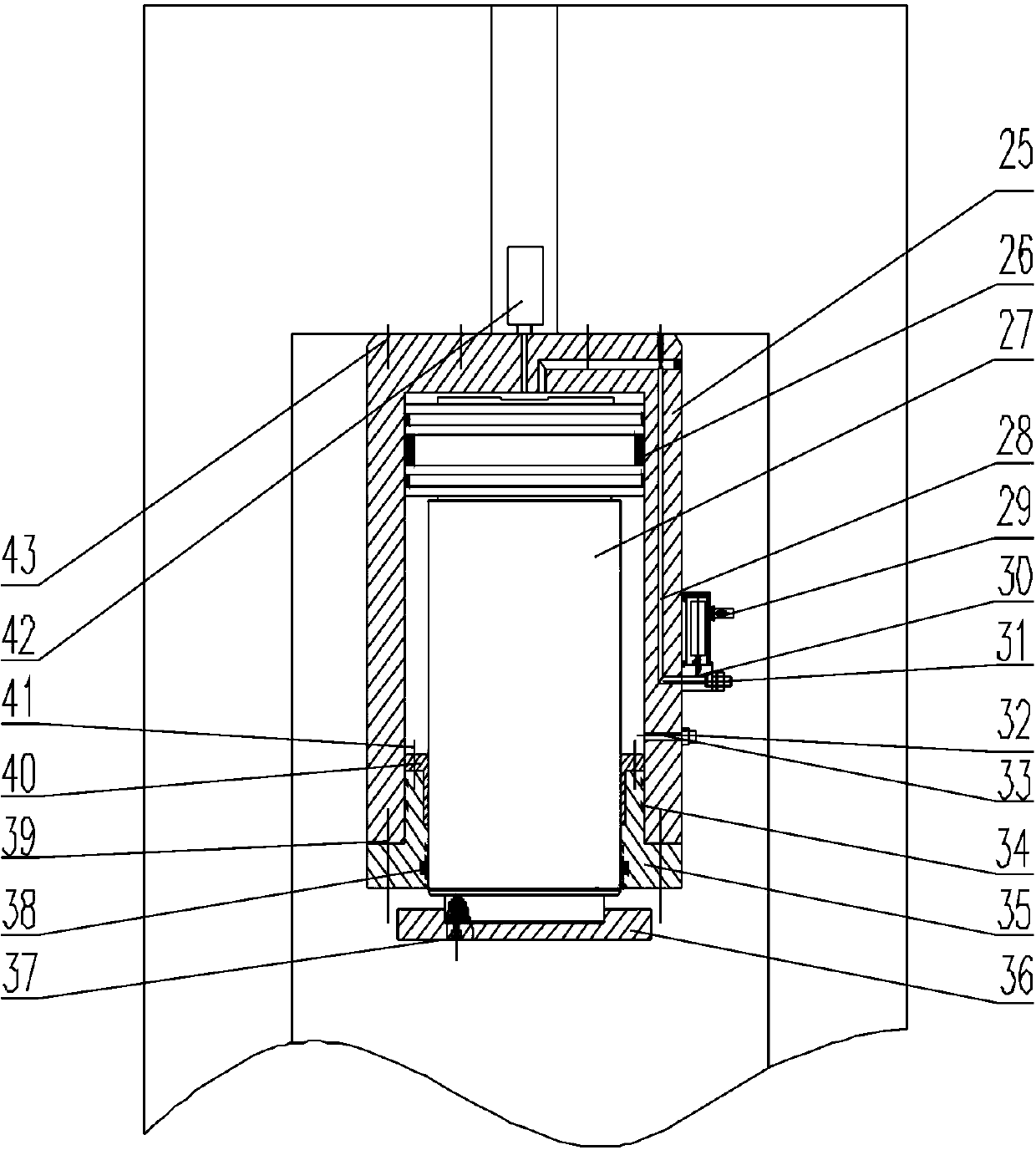

[0034] The hydraulic cylinder of the new hot rolling mill is a pressing hydraulic cylinder, which is embedded under the window of the archway of the hot roughing mill, with the piston head facing up; the upper part of the motor drives the pressing down screw to realize fast pressing down, and the lower part of the upper pressing hydraulic cylinder presses the upper pair of rolls at a low speed seam for fine-tuning.

Embodiment 2

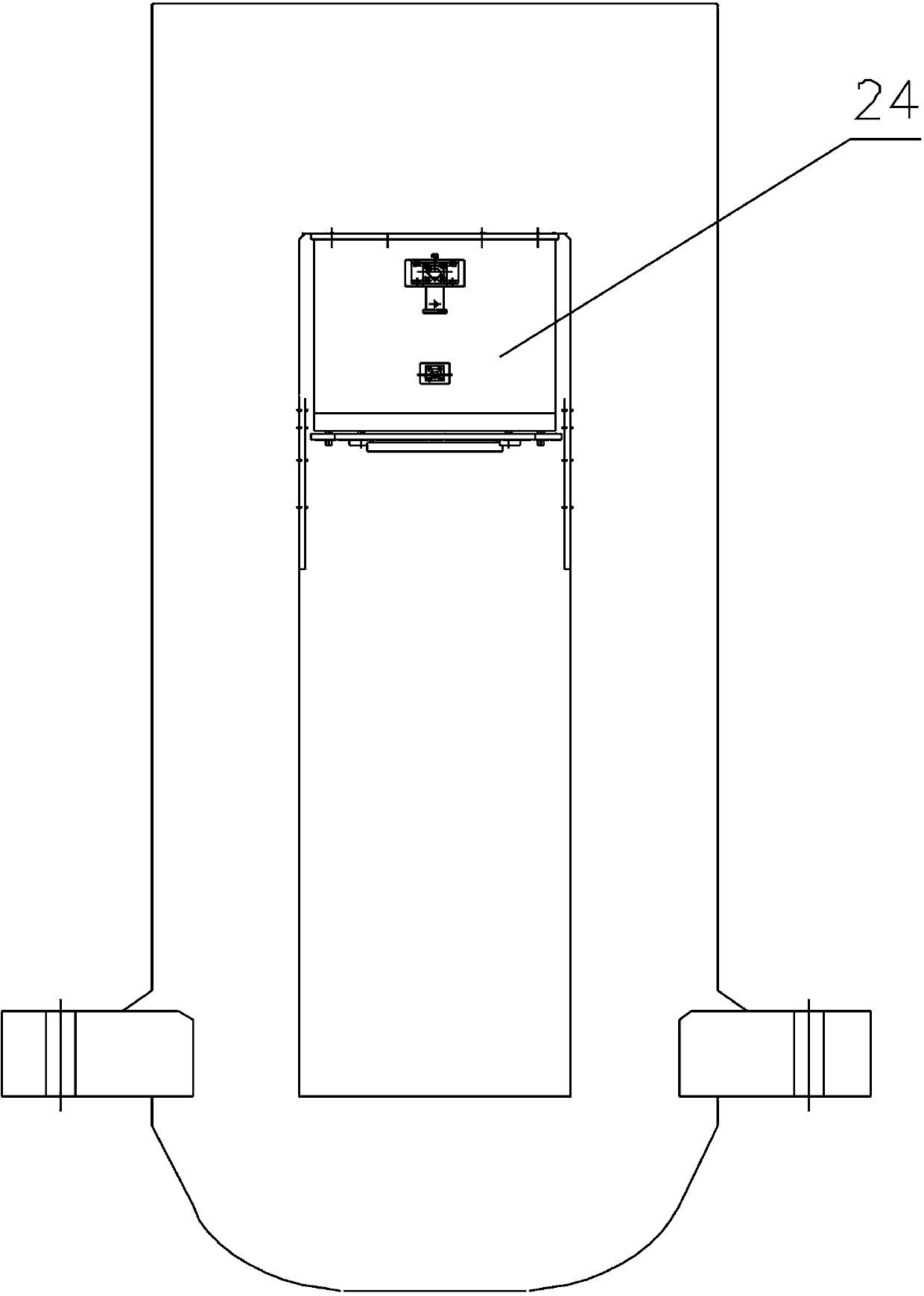

[0036] The hydraulic cylinder of the new hot rolling mill is a pressing hydraulic cylinder, which is embedded in the top of the window of the hot rolling mill archway, and the piston moves downward to realize the pressing action.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap