Heat dissipation torque motor cover used for hydraulic actuator servo valve

A torque motor and hydraulic actuation technology, which is applied in the field of structural design of hydraulic actuator servo valves, can solve problems such as increasing zero bias, affecting the performance of servo valve torque motors, and the performance of hydraulic actuator servo valves cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

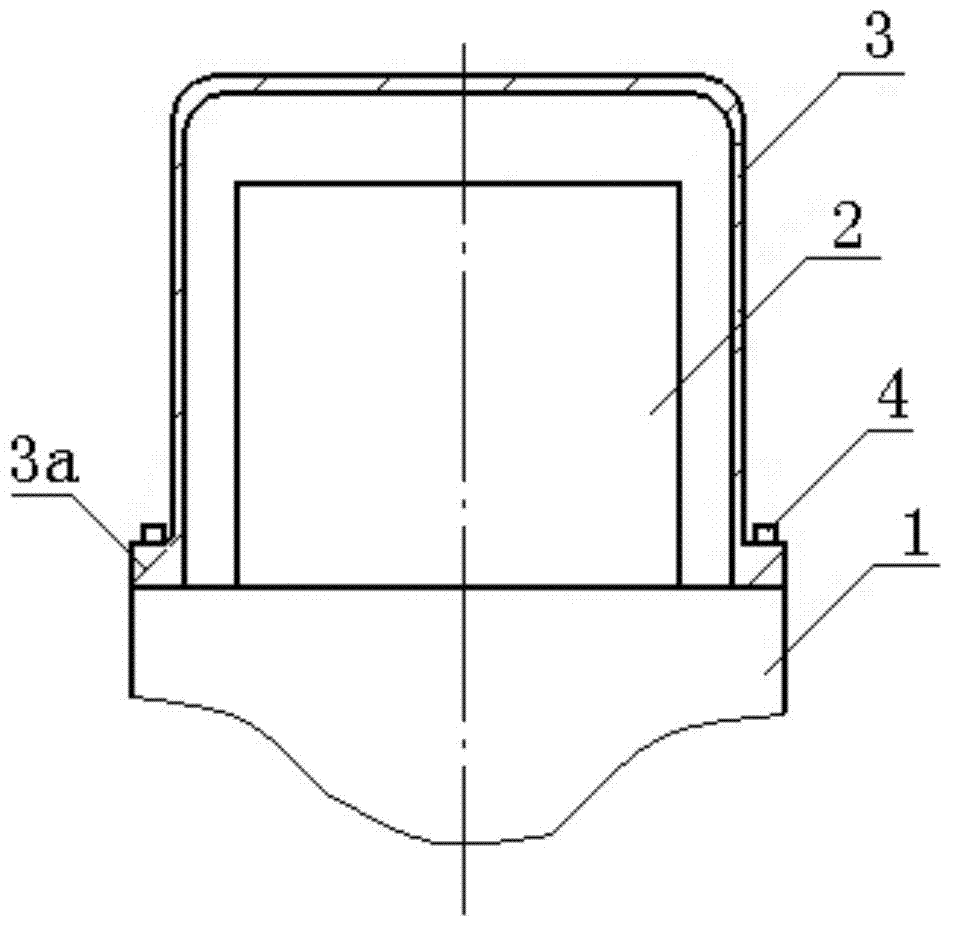

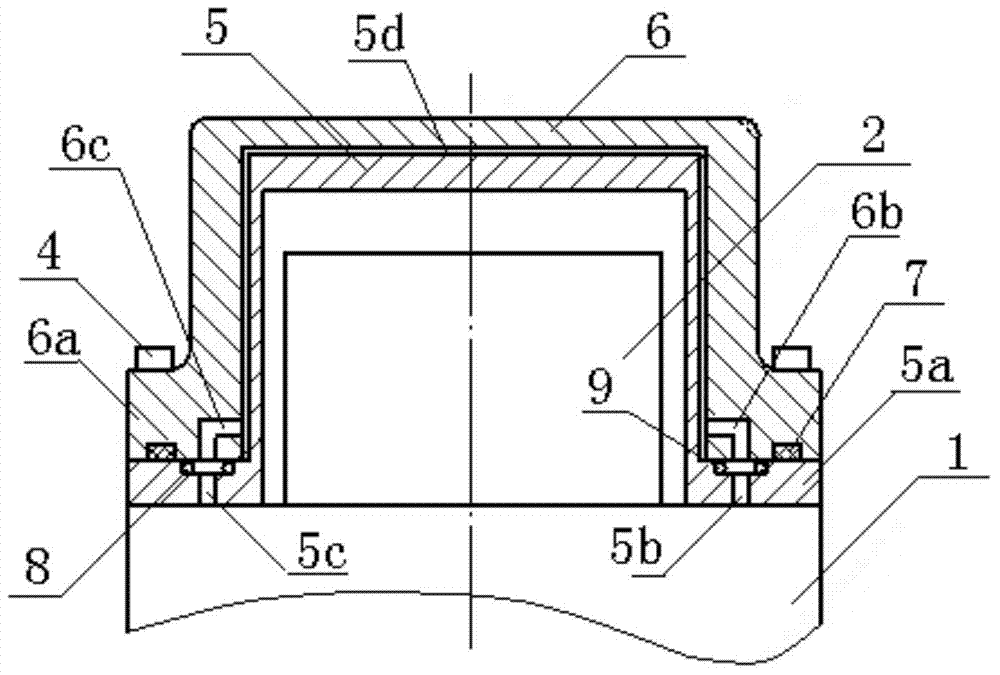

[0008] The present invention will be described in further detail below. see figure 2 , the heat dissipation torque motor cover for the hydraulic actuator servo valve, including the valve body 1 and the torque motor 2 installed on the torque motor installation plane of the valve body 1, there is a mounting flange on the outside of the torque motor 2, A torque motor cover with a circular or rectangular cross section, the mounting flange of the torque motor cover is fixed on the torque motor installation plane of the valve body 1 by screws 4; 6 double-layer covers formed by coaxial stacking, the outer surface of the inner cover 5 is attached to the inner surface of the outer cover 6, the upper surface of the mounting flange of the inner cover 5 is attached to the lower surface of the mounting flange of the outer cover 6, and the screw 4 Fix the mounting flange of the inner cover 5 and the mounting flange of the outer cover 6 on the torque motor installation plane of the valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com