Chip defect detection method

A defect detection and detection method technology, applied in the direction of measuring devices, semiconductor/solid-state device testing/measurement, instruments, etc., can solve problems such as defect detection and analysis, difference in brightness and darkness of contact holes, device instability, etc., to achieve stability and The effect of effective defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

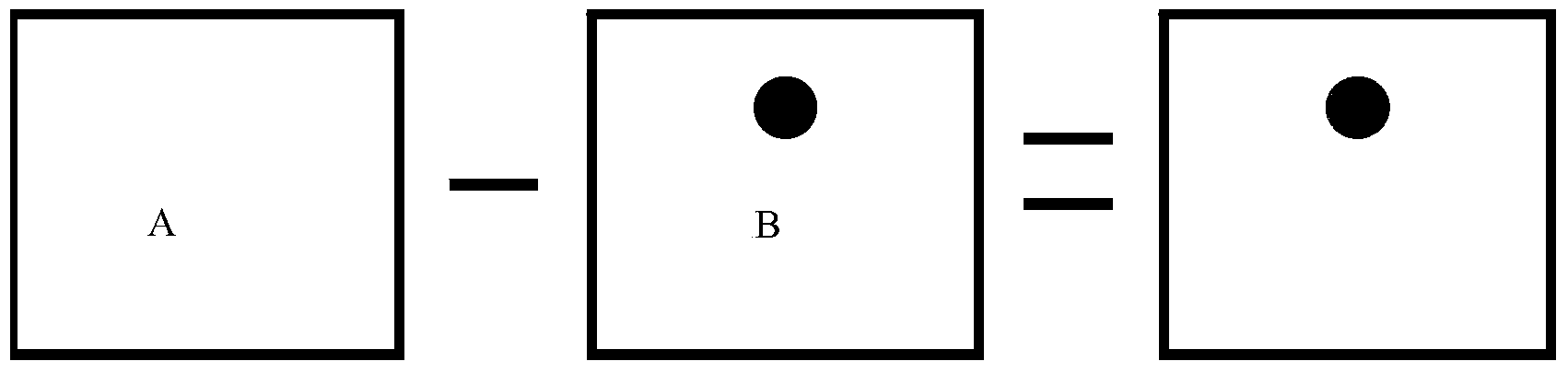

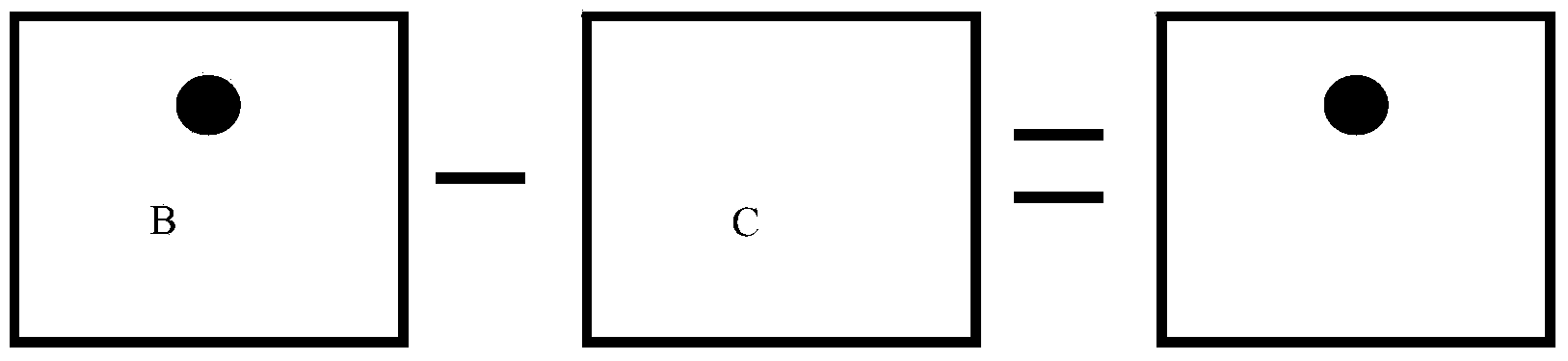

[0039] like Figure 5 , Figures 7a-7d and Figures 8a-8d As shown, the present embodiment relates to a method for detecting chip defects, comprising the following steps:

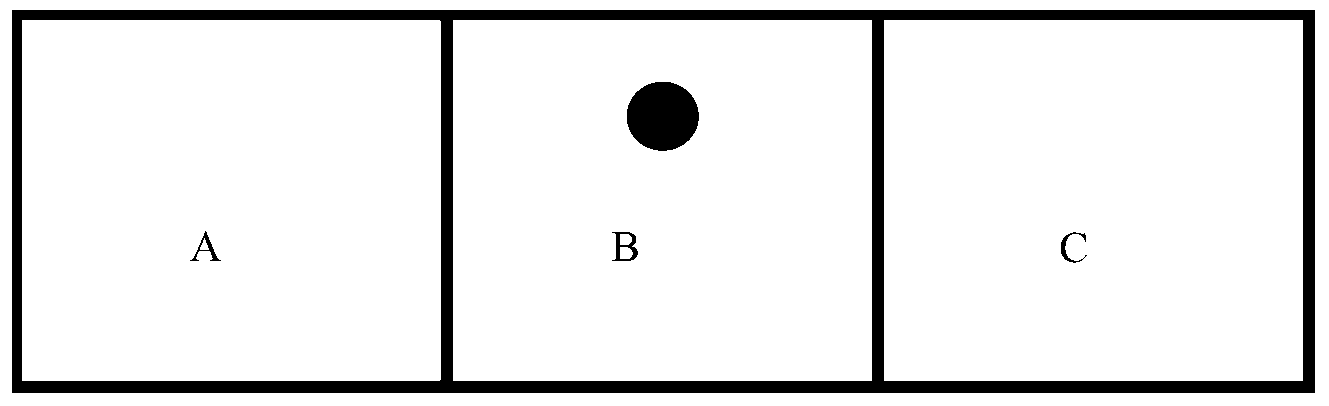

[0040] First, provide a chip set with four devices A, B, C, and D to be tested and a defect detection equipment;

[0041] Import the ion implantation circuit diagrams of the four devices A, B, C, and D on each chip in the chipset to be tested into the defect detection equipment respectively, 51, 52, 53, and 54 are respectively A, B, C, and D The photoresist area in the circuit diagram of the ion implantation of the four devices, the photoresist area can cover the scanning area of the defect detection equipment;

[0042]The defect detection conditions of the four devices A, B, C, and D are respectively set, so that the four devices of A, B, C, and D are in a stable state under their respective defect detection conditions, and the defect detection of the imported ion implantation circuit diagram Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com