Weaving method of three-dimensional shoe upper

A shoe upper and three-dimensional technology, applied in the field of weaving, can solve the problems of high shoe upper weaving waste, high labor cost, uneven needle driver proficiency, etc., achieve environmental protection destruction costs, reduce shoe upper waste, and reduce destruction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to facilitate the understanding of the inventive features, content and advantages of the present invention and the effects that can be achieved, the present invention is now combined with the accompanying drawings, and is described in detail as follows in the form of embodiments, and the accompanying drawings used therein only have its gist For the purpose of illustrating and assisting the description, it may not be the true proportion and precise configuration of the present invention after implementation. Therefore, the proportion and configuration relationship of the attached drawings should not be interpreted or limited to the scope of rights of the present invention in actual implementation. .

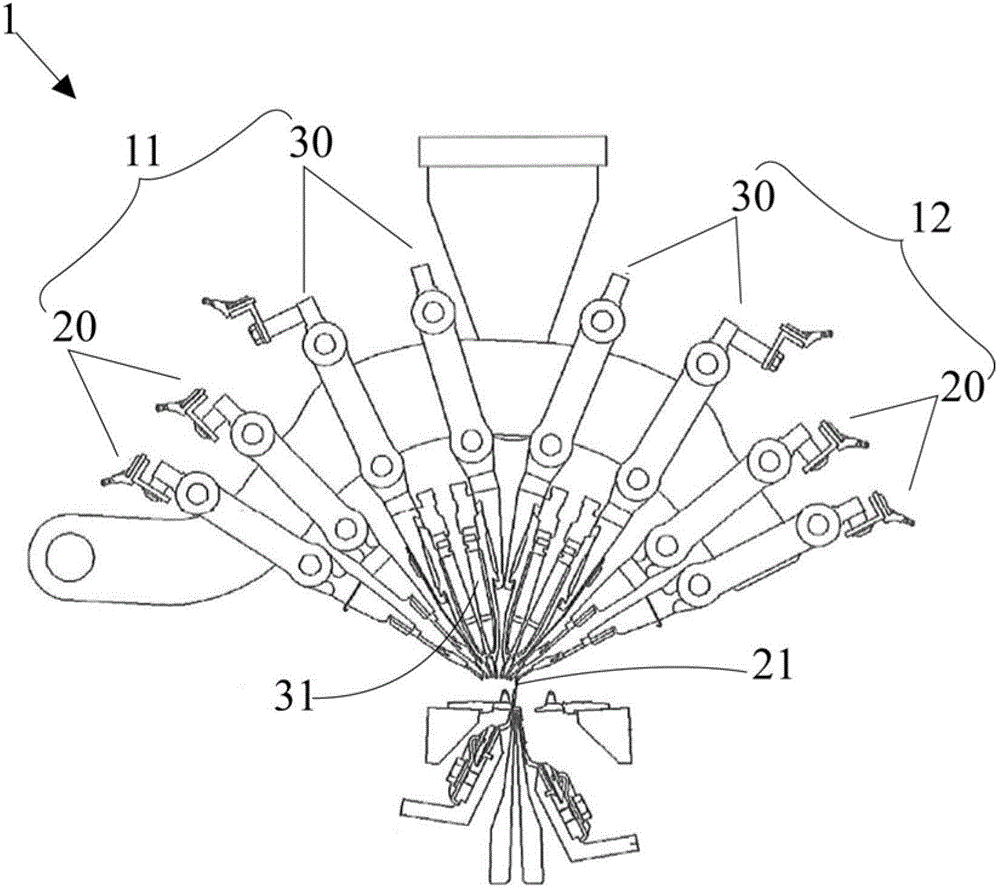

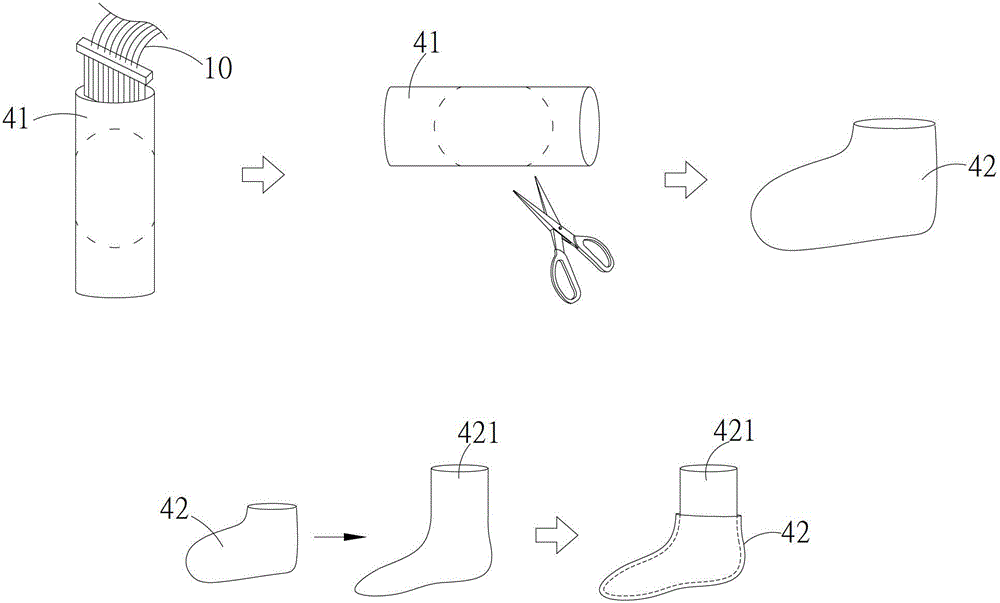

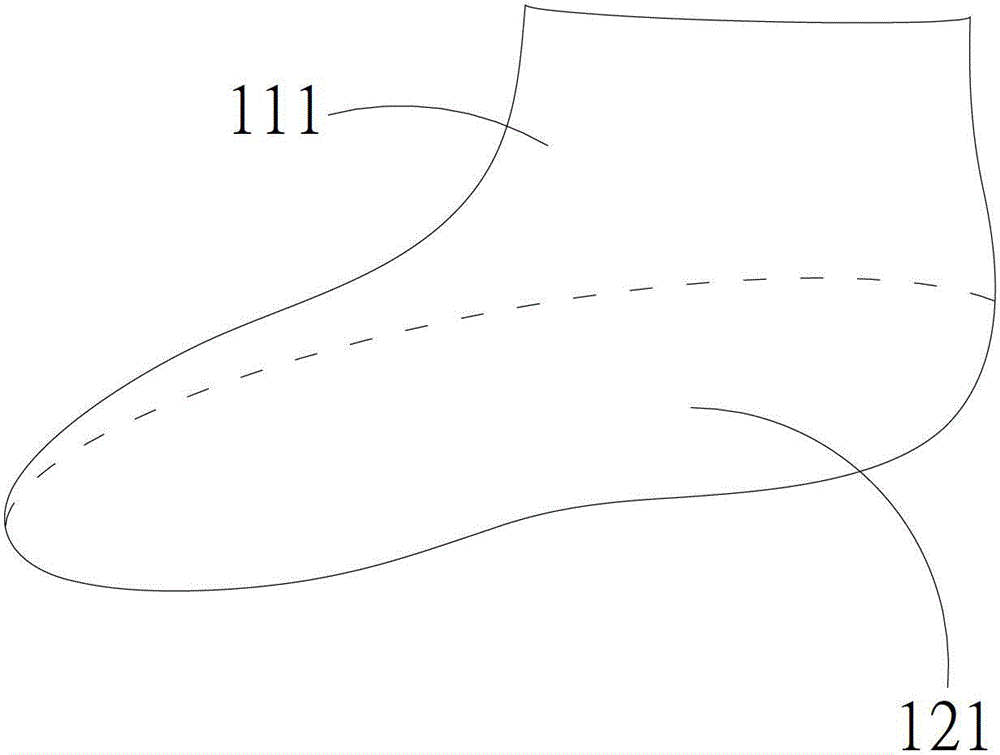

[0038] The weaving method of the three-dimensional vamp according to the present invention will be described in detail below in conjunction with the relevant drawings. For ease of understanding, the same components in the following embodiments are described with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com