Veterinary syringe destroying device

A technology for destroying devices and syringes, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve the problems of waste, no recycling of useful parts of syringes, high energy consumption, etc., to achieve less virus infection and reduce destruction costs. , the effect of good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

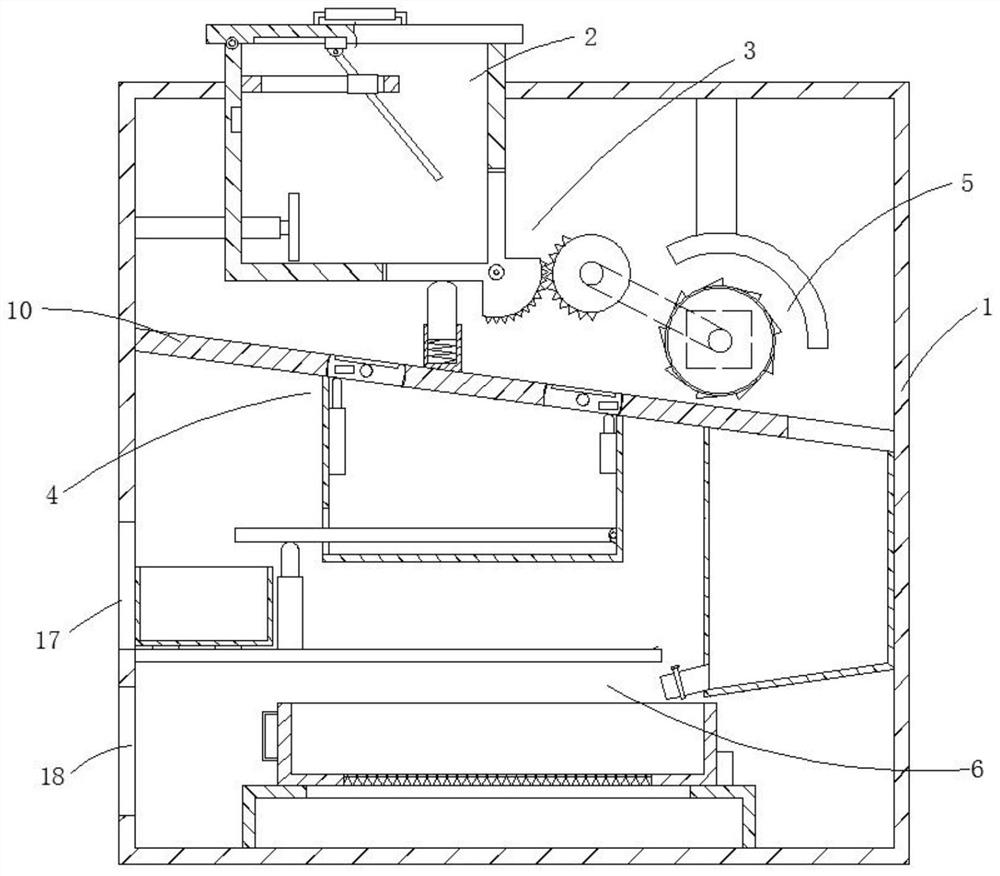

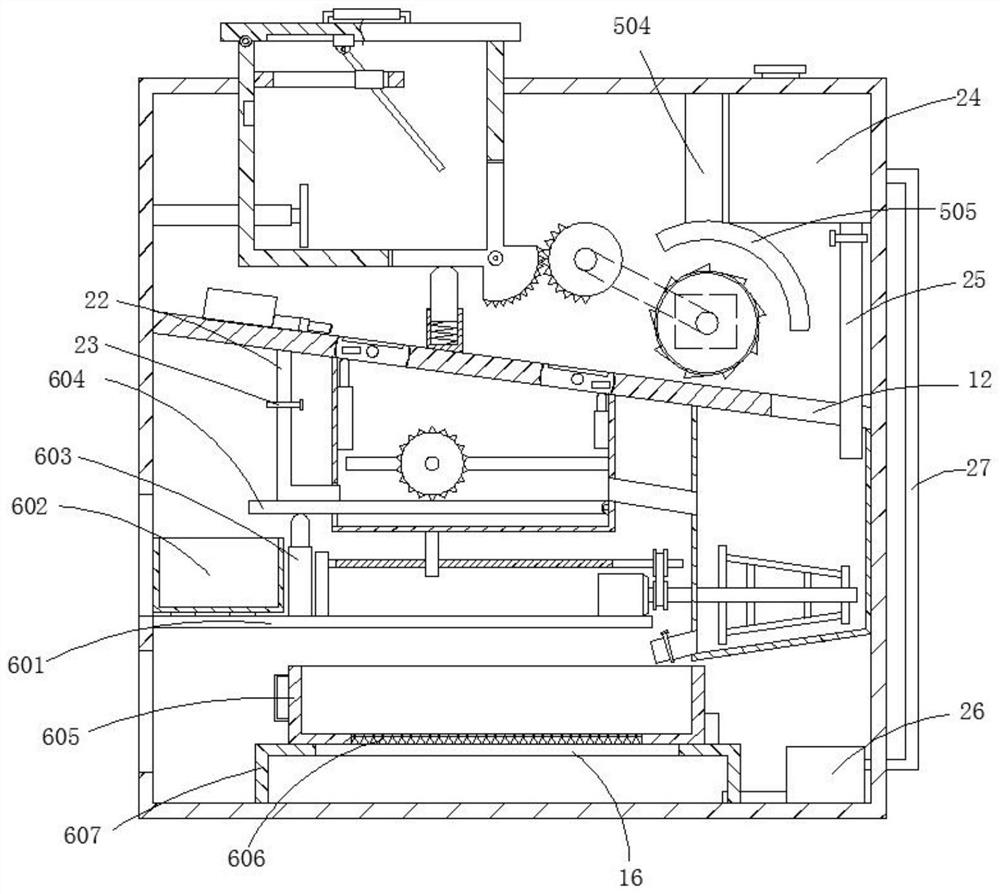

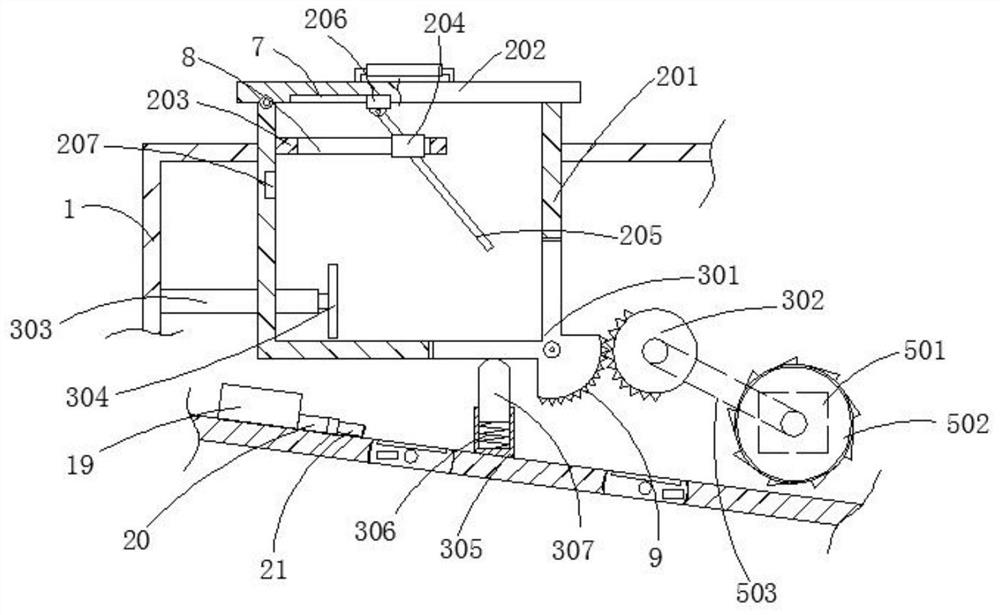

[0040] see Figure 1-7 , the present invention provides a technical solution: a veterinary syringe destruction device, comprising a main body box 1, a pre-sterilization mechanism 2, a feeding mechanism 3, a separation structure 4, a crushing mechanism 5 and a collection mechanism 6, the pre-sterilization mechanism 2 includes a disinfection Case 201, case cover 202, limit plate 203, slide block 204, reflector plate 205, connection block 206 and ultraviolet germicidal lamp 207, disinfection case 201 is connected on the top of main body case 1, and case cover 202 is hinged on the top of disinfection case 201 , the top of the box cover 202 is provided with a chute 7, the connecting block 206 is slidably connected in the chute 7, the limiting plate 203 is fixedly connected on the left side wall of the disinfection box 201, and the top of the limiting plate 203 is provided with a limiting groove 8. The slider 204 is slidably connected in the limit groove 8, the reflector 205 is fixe...

Embodiment 2

[0046] On the basis of embodiment 1;

[0047] Wherein, the left side of support plate 10 is also provided with auxiliary unloading mechanism, and auxiliary unloading mechanism comprises blower fan 19, output pipe 20, nozzle 21, branch pipe 22 and control valve 23, fan 19 is installed on the top of support plate 10, output pipe 20 communicates with the air outlet of the fan 19, the nozzle 21 is connected to the other end of the output pipe 20, one end of the branch pipe 22 communicates with the output pipe 20, and the other end extends into the separation chamber 401 through the discharge port 14, and the control valve 23 is installed in the branch pipe 22 on.

Embodiment 3

[0049] On the basis of embodiment 2;

[0050] Wherein, the main body box 1 is also provided with a disinfection mechanism. The disinfection mechanism includes a liquid medicine tank 24, a drain pipe 25, a connection pump 26 and a connection pipe 27. The pipe 25 is communicated with the bottom of the liquid medicine tank 24, and the bottom end of the drain pipe 25 extends into the processing tank 13, and the connecting pump 26 is installed on the bottom of the main body box 1, and communicates with the inner chamber of the support base 207, and the connecting pipe 27 It is connected between the connection pump 26 and the chemical solution tank 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com