Flat knitting machine with loop forming tablet and its control method

A technology of sheet forming and flat knitting, which is applied in the direction of flat knitting, textile and paper making, weft knitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

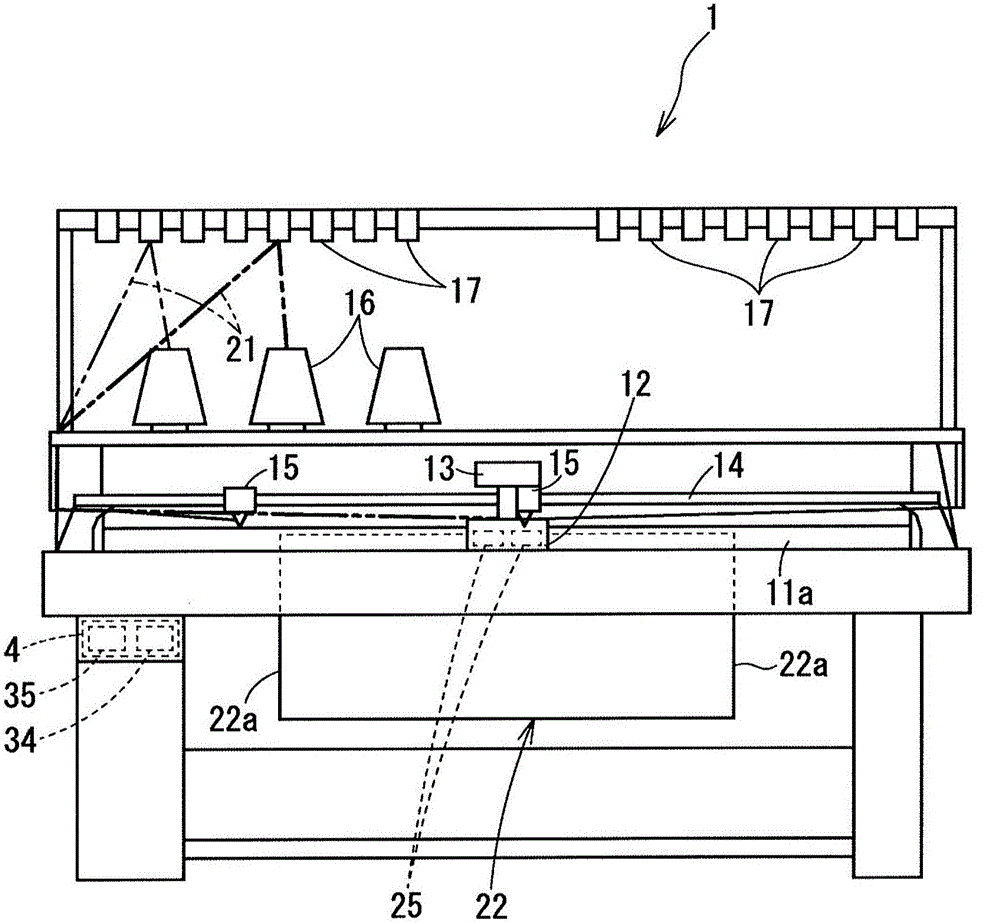

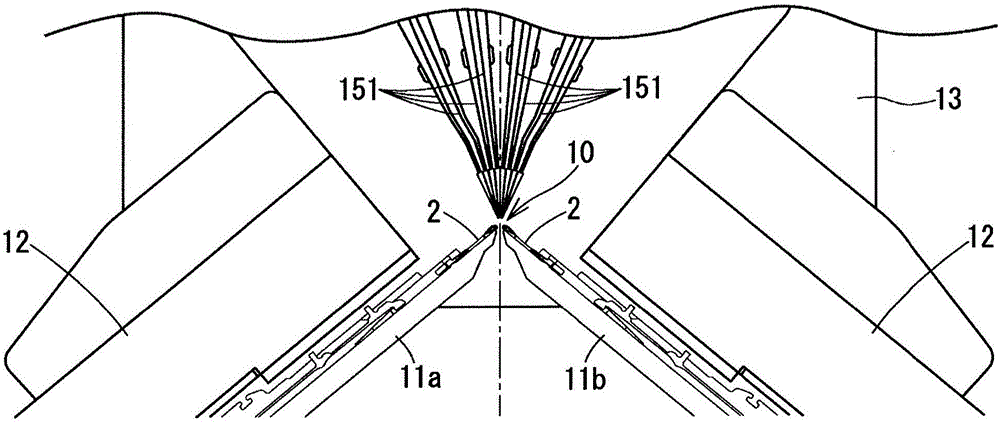

[0056] figure 1 A schematic structure of a flat knitting machine equipped with a knitted fabric sheeting according to an embodiment of the present invention is shown, figure 2 express figure 1 A longitudinal side view of the flat knitting machine near the tooth gap.

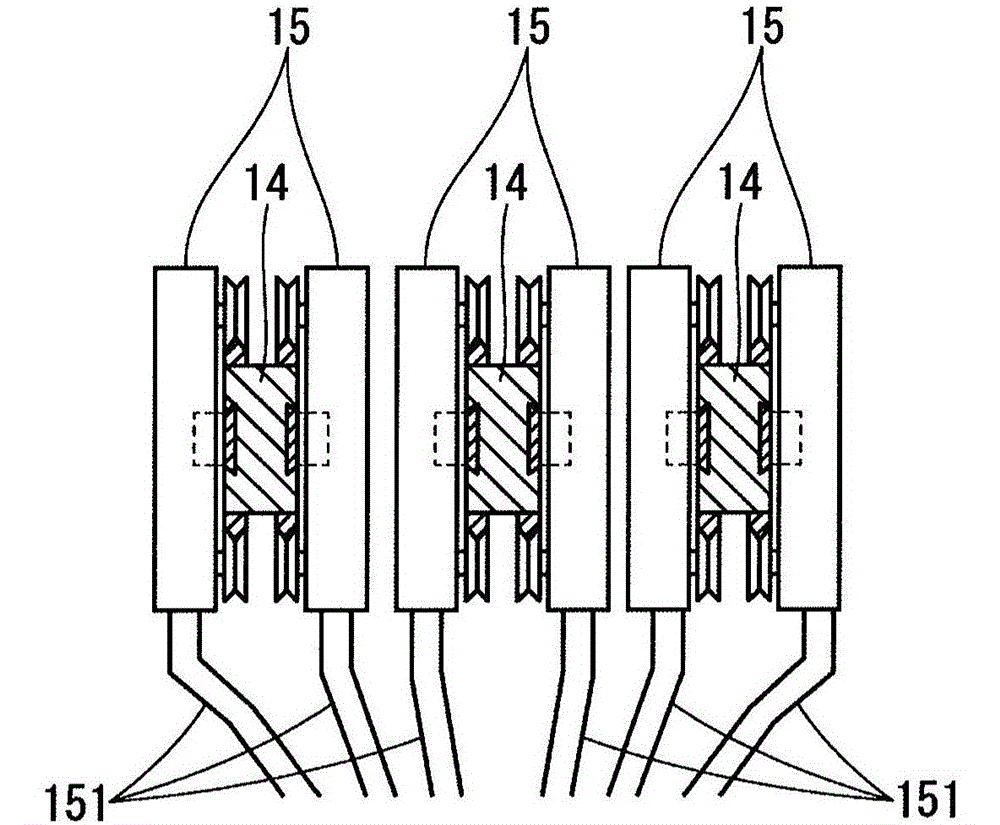

[0057] figure 1 and figure 2 Among them, the flat knitting machine 1 includes front and rear needle beds 11 a and 11 b facing each other in an inverted V shape with a needle bed 10 interposed therebetween. The front and rear needle beds 11a, 11b are respectively provided with a carriage 12, and the front and rear carriages 12 are connected by a bridge 13 at the needle bed 10 portion. Each cam carriage 12 is driven by a servo motor not shown, along the length direction of the needle beds 11a, 11b ( figure 1 middle for the left and right direction) reciprocating movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com