Electrical conductor splicing device

A technology for splicing electric wires, applied in the field of splicing devices for electric wires, which can solve the problems of increased resistance, weak joints, and heat generation of joints, and achieves the effects of simple structure, simple and portable device, and fast twisting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

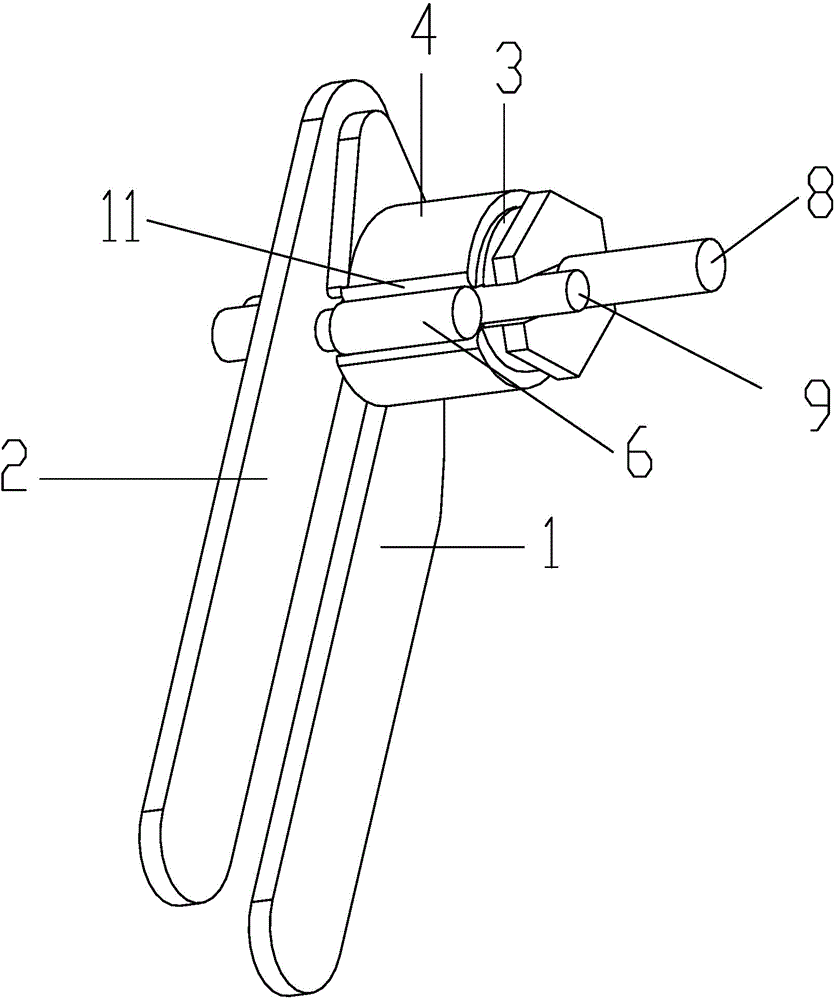

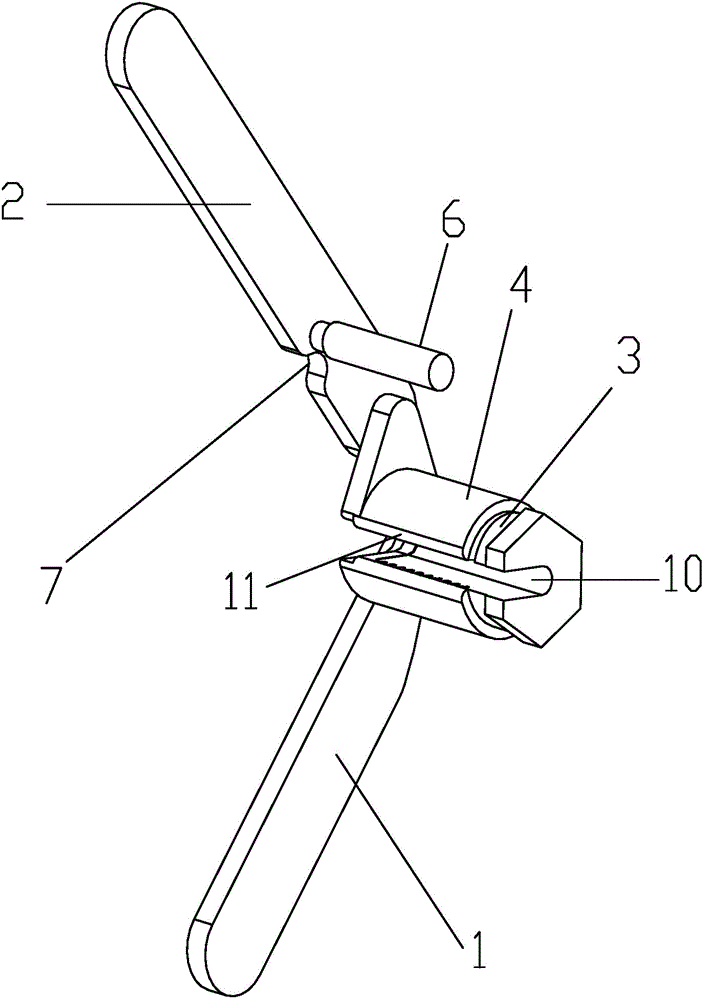

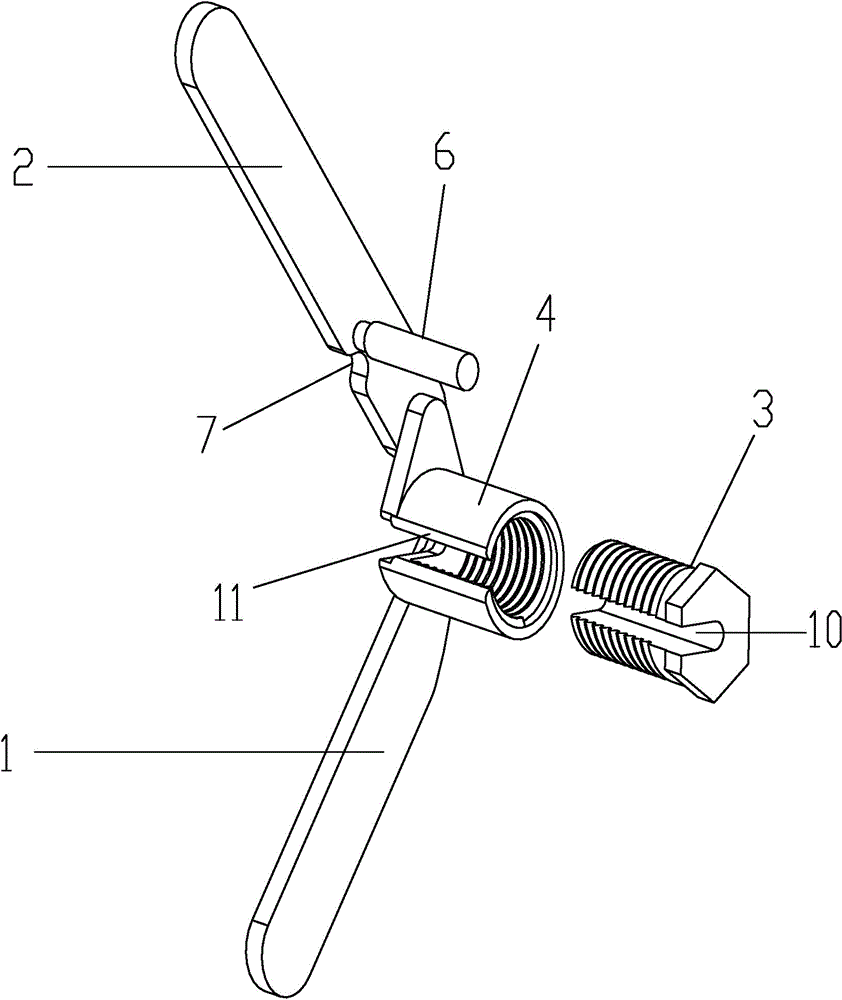

[0016] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

[0017] An electric wire splicing device, which includes a rotating rod sleeve 4 sealed at the left end and a rotating rod 3 nested in the rotating rod sleeve 4 and rotatingly matched with the rotating rod sleeve 4 through a thread structure; the rotating rod 3 is provided with The wire accommodating groove 10 of the rotating rod 3 is penetrated axially, and the wire receiving opening 11 corresponding to the wire accommodating groove 10 is provided on the rotating rod sleeve 4 . When the two wires to be spliced are put into the wire accommodating groove 10 through the wire insertion opening 11, the axis of the wire A8 near or against the bottom of the wire accommodating groove 10 is coaxial with the rotation axis of the rotating rod 3, and the wire B9 Place it close to wire A8.

[0018] The invention can not only re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com