A round tube rotation assisting device

A round tube and rotary block technology, applied in the direction of workpiece manipulation, can solve the problems of increasing energy consumption and labor costs, increasing enterprise operating costs, and unfavorable automation of loading and unloading, so as to facilitate production automation, reduce energy consumption, and prevent running Partial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

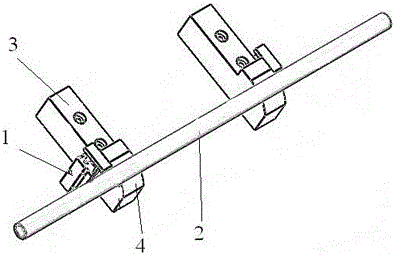

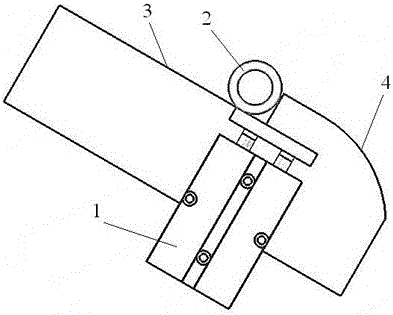

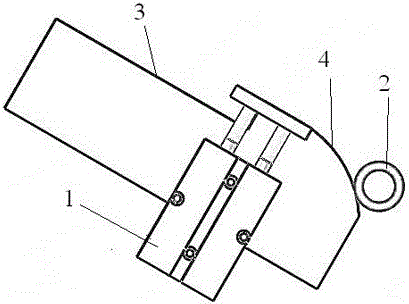

[0016] see Figure 1 to Figure 3 , a round tube rotation assisting device of the present invention includes: several rotation assisting blocks and a cylinder 1 located on the side of the rotation assisting blocks, wherein the rotation assisting blocks are arranged obliquely, and the round tube 2 has a tendency to slide down by using the gravity of the round tube 2 itself . In order to facilitate the control of the feeding frequency of the round tube 2 according to the production process, the rotation aid forms a placement platform 3 for placing the round tube 2 and a slideway 4 for the round tube 2 to accelerate to slide down. At the entrance of the placement platform 3 and the slideway 4 There is a height difference between them, to prevent the circular pipe 2 from entering the slideway 4 automatically. Such as figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com