Patents

Literature

48results about How to "Facilitate production automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery and preparation method thereof

ActiveCN101867070AThe problem of losing viscosity failure will not existImprove high temperature resistanceElectrode manufacturing processesFinal product manufactureLithium-ion batteryLithium electrode

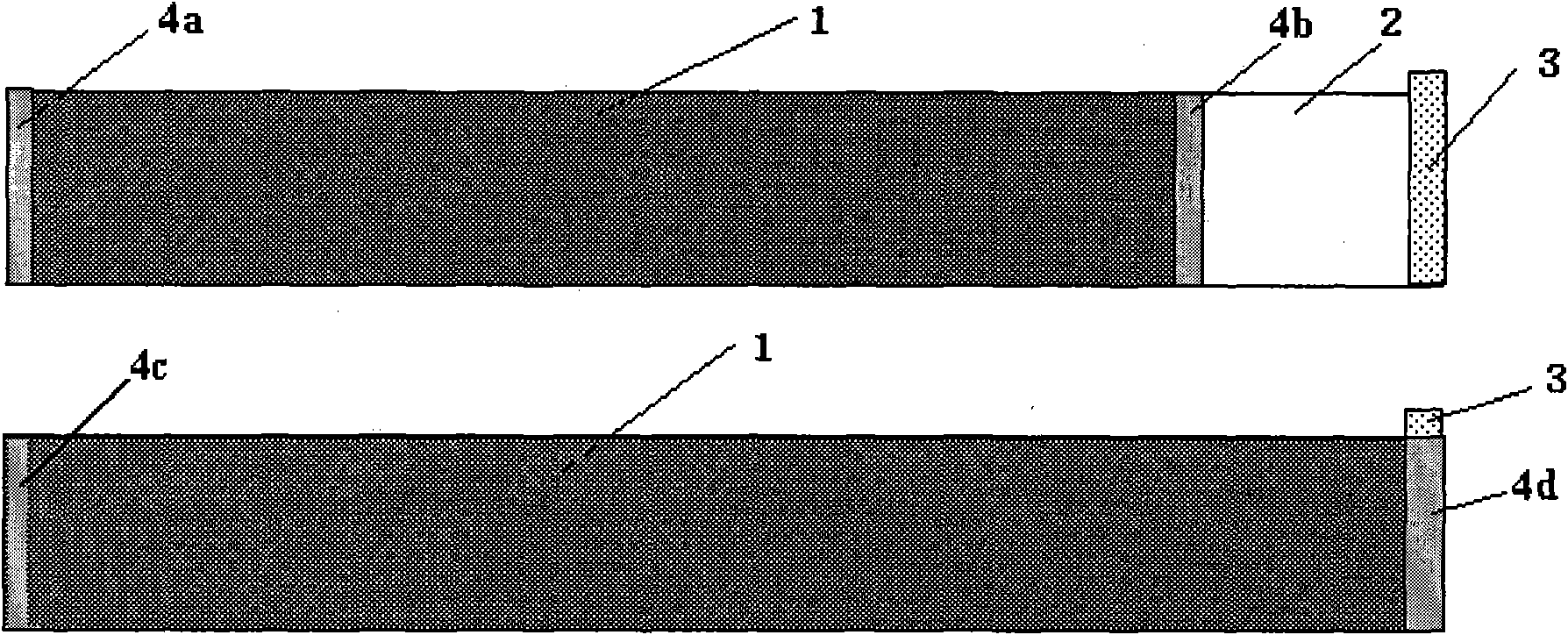

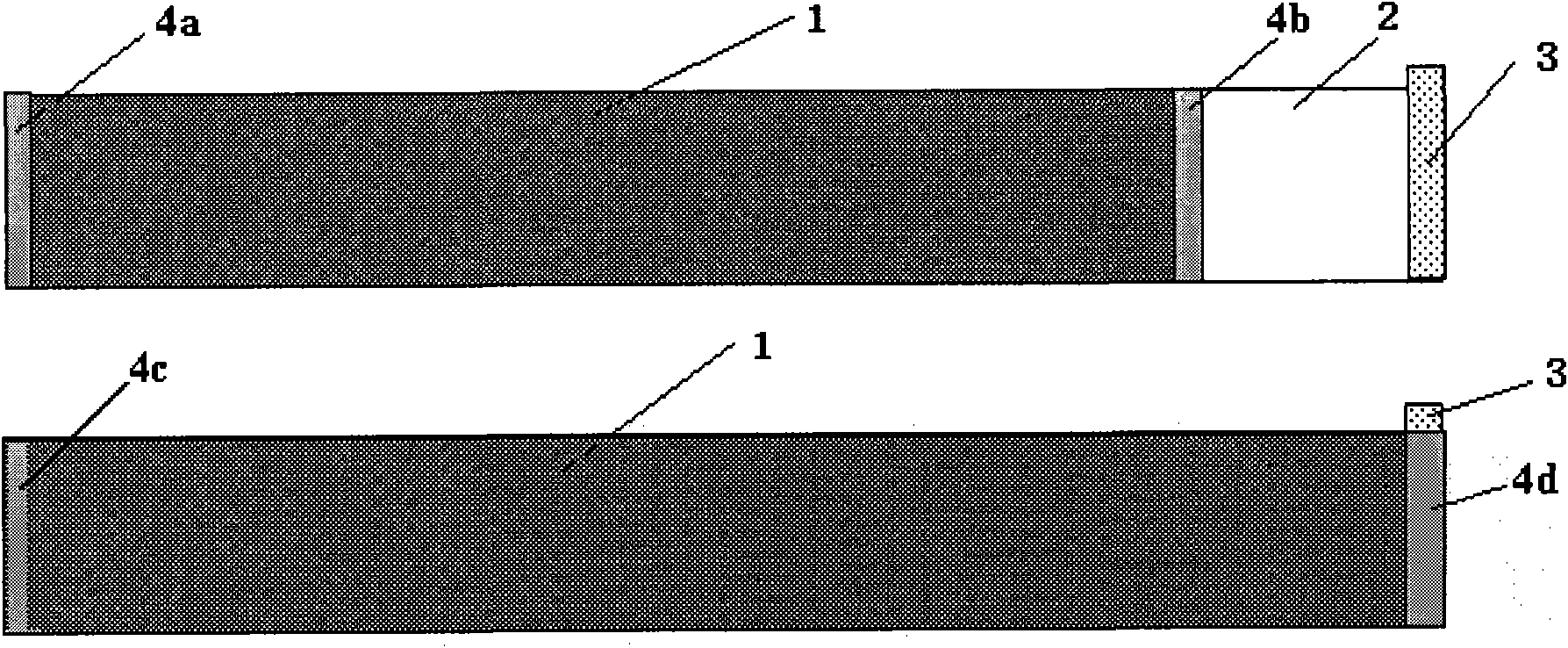

The invention provides a lithium ion battery and a preparation method thereof. Insulating coating layers are arranged in at least the following areas of the battery: 1. an area which is on the other surface of a positive plate and corresponds to an area in which a positive pole tab is jointed with a positive pole current collector; and 2. an area which is on the other surface of a negative pole tab and corresponds to an area in which the negative pole tab is jointed with a negative pole current collector, and an area which is on the other surface of a negative plate and corresponds to an areain which the negative pole tab is jointed with the negative pole current collector. Through using the insulating coating layers to substitute for adhesive tapes, the invention has the advantages thatthe high-temperature safety of the battery is improved, and the initial capacity of the battery can be improved because the insulating coating layers have certain ability of passing lithium ions.

Owner:BYD CO LTD

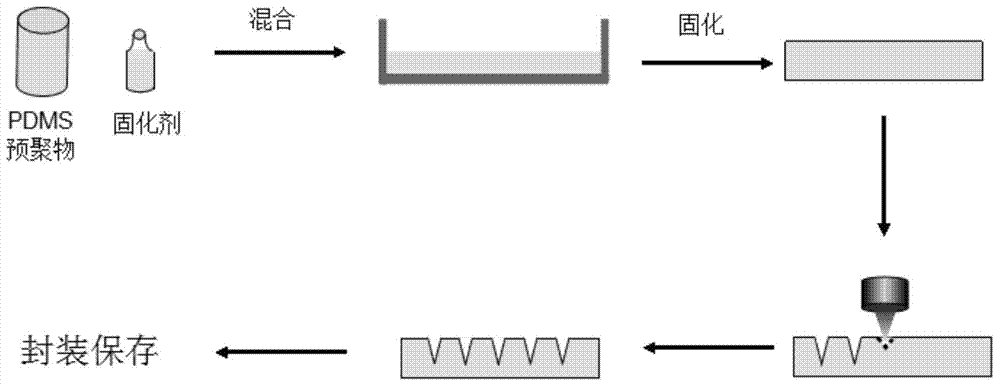

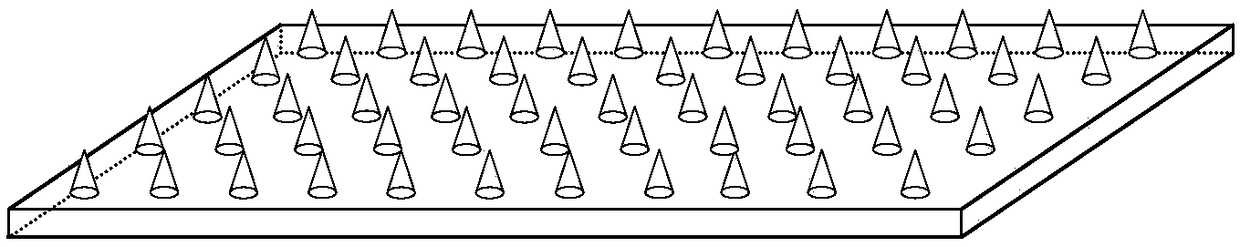

Microneedle template and preparation method thereof

InactiveCN104844814AGood micropore uniformityImprove uniformityMicroneedlesMedical devicesDimethyl siloxaneLaser beams

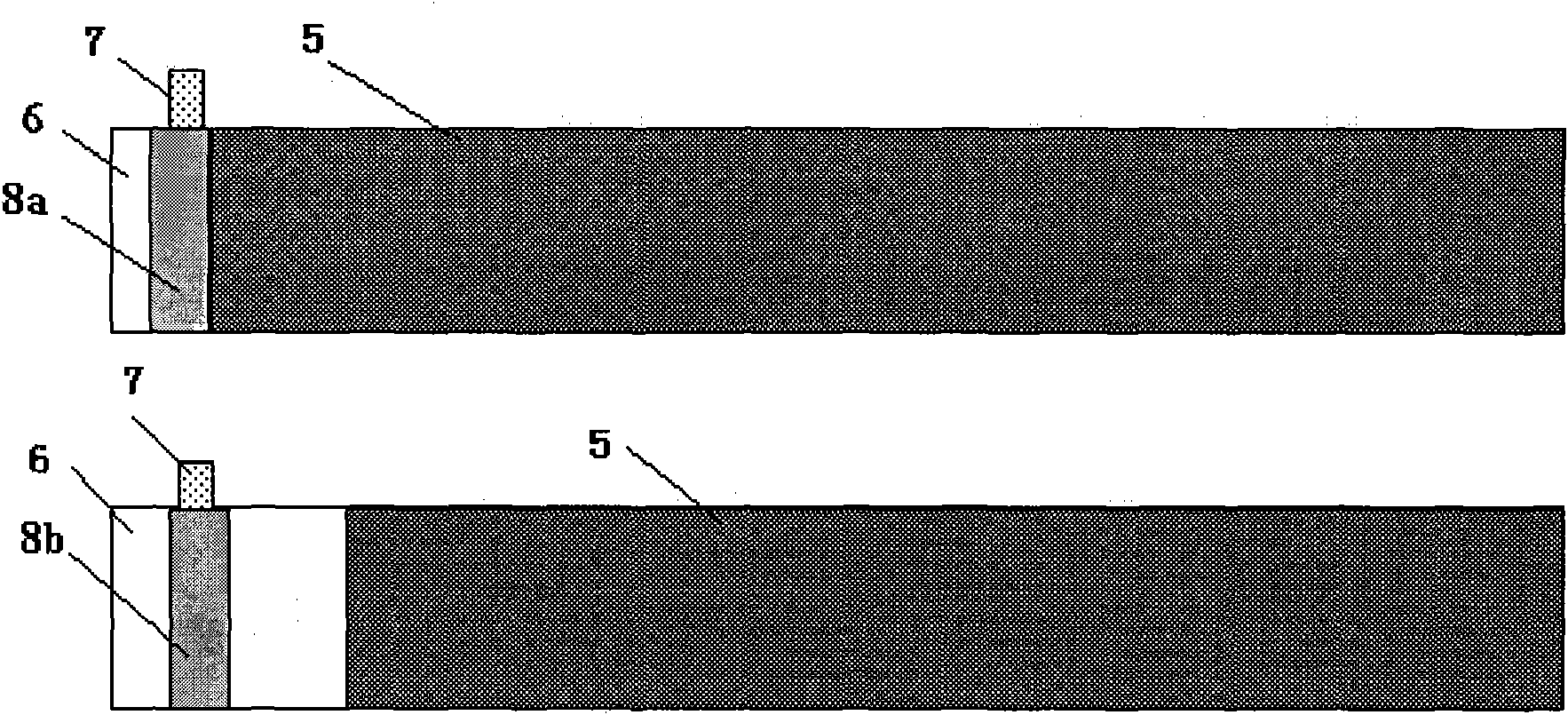

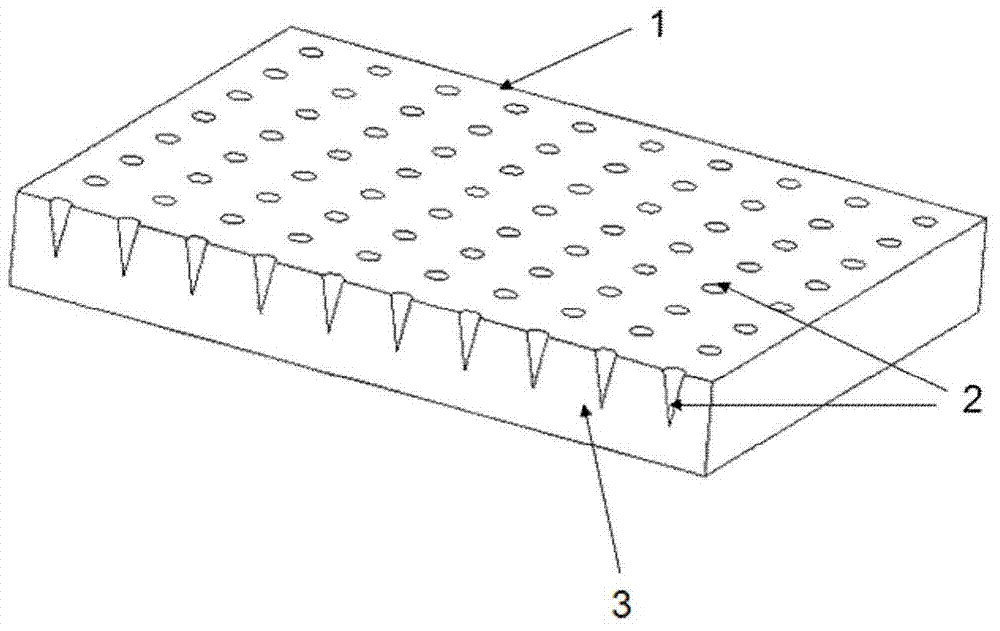

The invention belongs to the technical field of dosing equipment and specifically relates to a microneedle template and a preparation method thereof. The microneedle template is prepared from a polydimethylsiloxane film; a micropore array is formed in the surface of the polydimethylsiloxane film; and the polydimethylsiloxane film is prepared by mixing a polydimethylsiloxane film prepolymer and a curing agent. Compared with the prior art, the microneedle template is excellent in micropore uniformity; the template is firm and durable, and applicable to preparing microneedle products of a plurality of types by use of a melt or solution pouring method; and as being proven, the prepared microneedles can be applied to transdermal drug delivery or skin preprocessing. In addition, the preparation method only comprises directly perforating the surface of the polydimethylsiloxane only by use of a laser beam; the preparation material is simple, the method is simple and easy to implement, the preparation efficiency is high and the production automation can be realized; and besides, the shape and size of the micropores can be controlled by adjusting the laser energy parameter according to production requirements, and the microneedle templates of different structure parameters can be designed.

Owner:BEIJING UNIV OF CHEM TECH

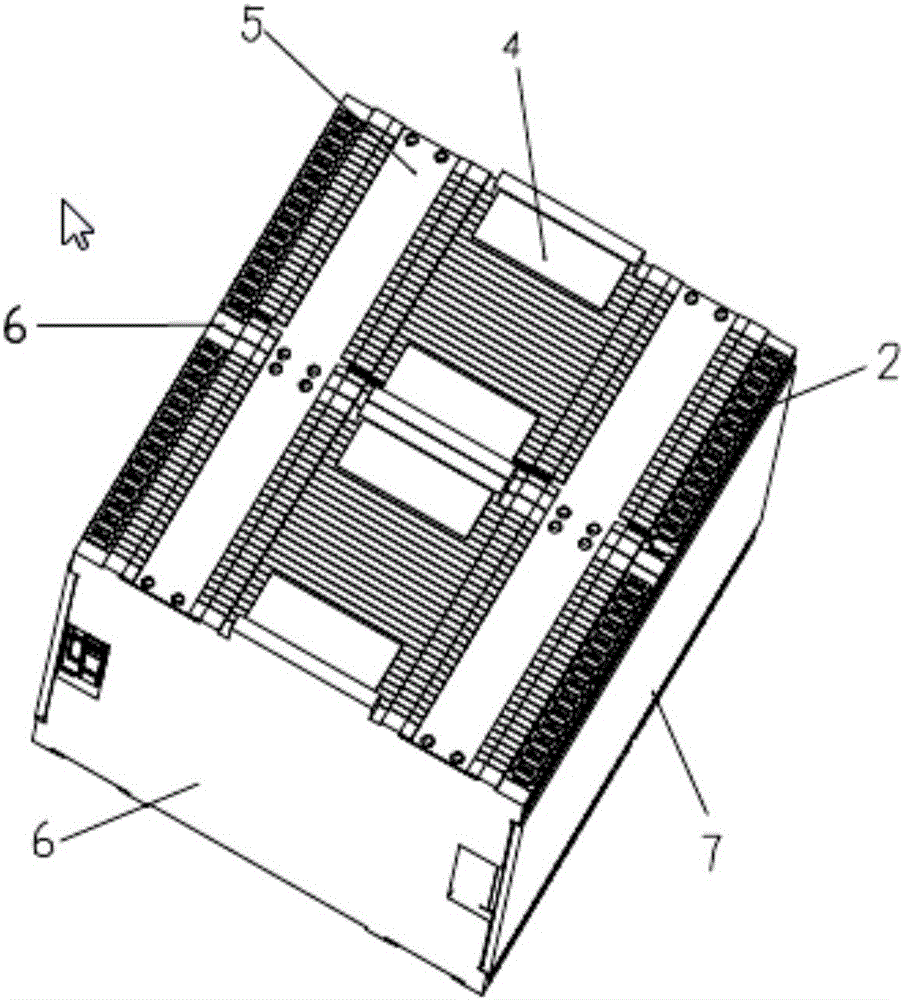

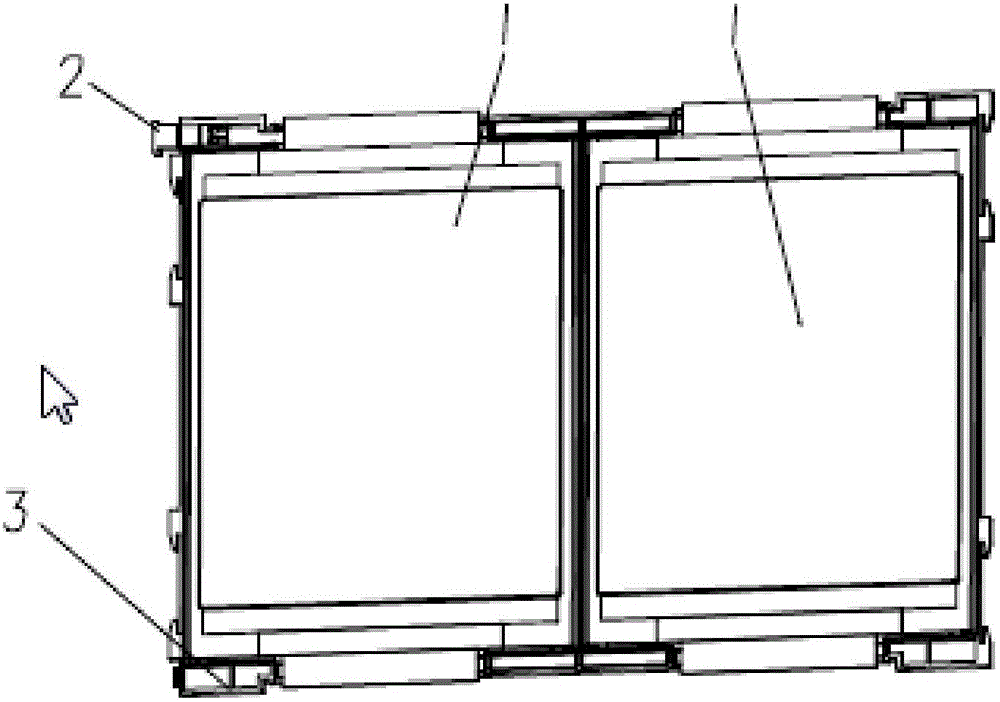

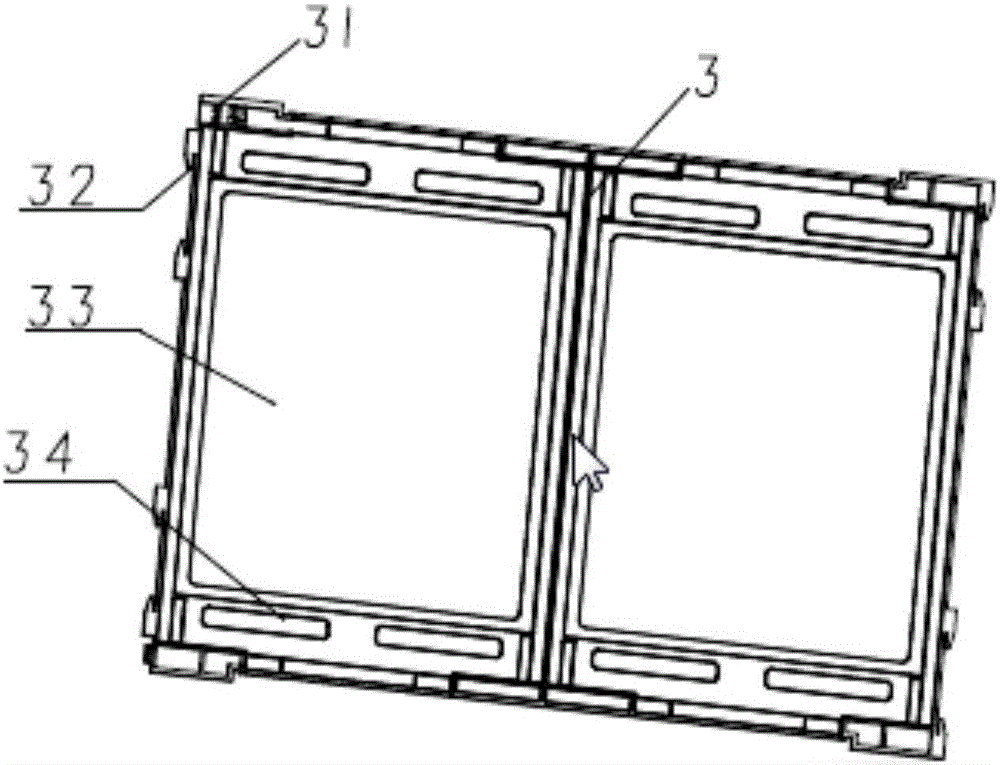

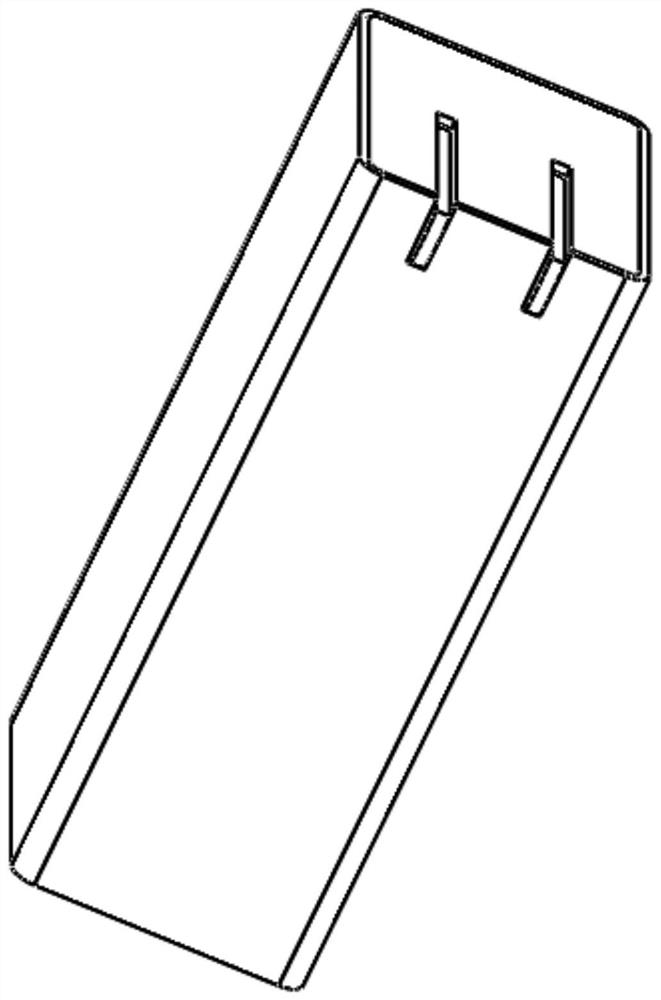

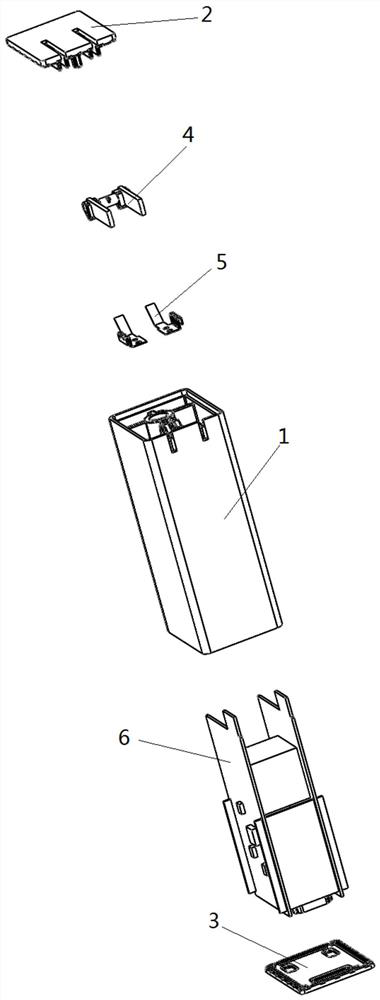

High and low voltage separated type aluminum laminated battery module

ActiveCN106025133AHigh strengthIncrease stiffnessSecondary cellsCell component detailsLow voltageFixed frame

The invention discloses a high and low voltage separated type aluminum laminated battery module. The high and low voltage separated type aluminum laminated battery module is composed of multiple battery assembly units. Each battery assembly unit comprises a battery fixing frame (3) and a battery cell (1), wherein an insertion piece installation port (31) is formed in the side face of the battery fixing frame (3), and an insertion pin (2) is installed in the insertion piece installation port (31) and welded to a battery tab. Fixing and clamping grooves (32) open in the same direction are formed in the side edges of the battery fixing frames (3), and connection of the multiple battery assembly units is achieved by clamping module fixing bars (5) in the fixing and clamping grooves (32). The battery module is standardized in structure, high in reliability, convenient to assembly and high in structural strength, and production efficiency can be improved greatly.

Owner:安徽天鑫能源科技有限公司

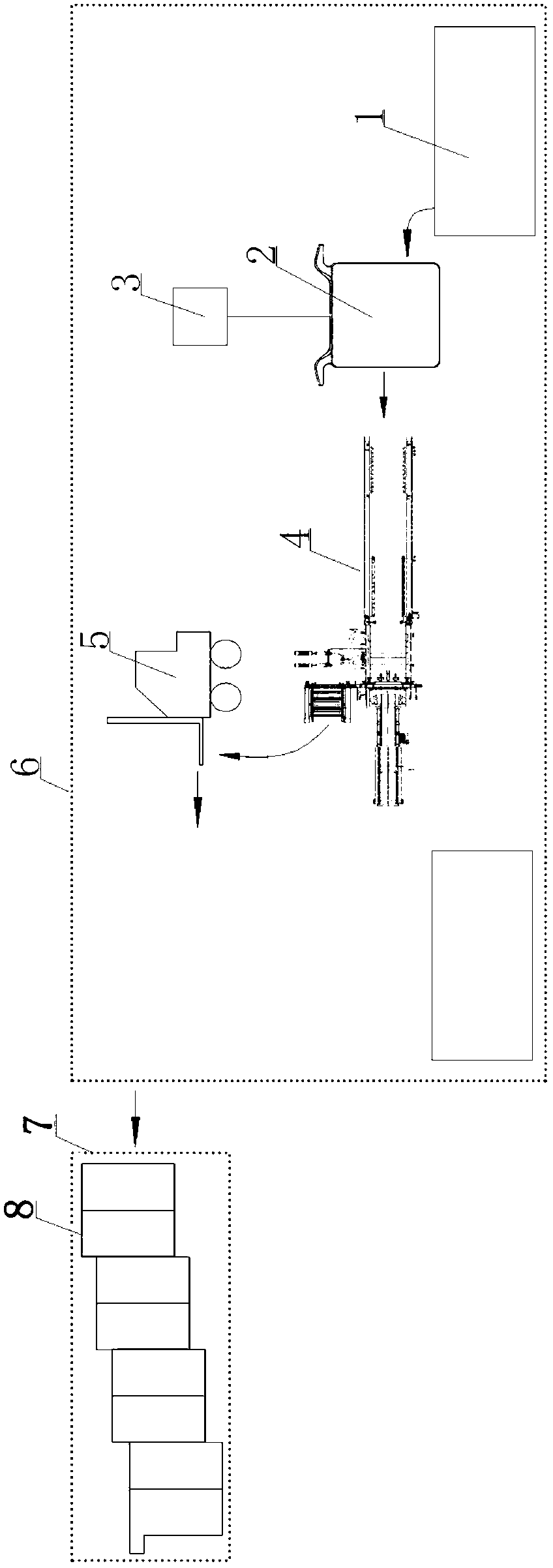

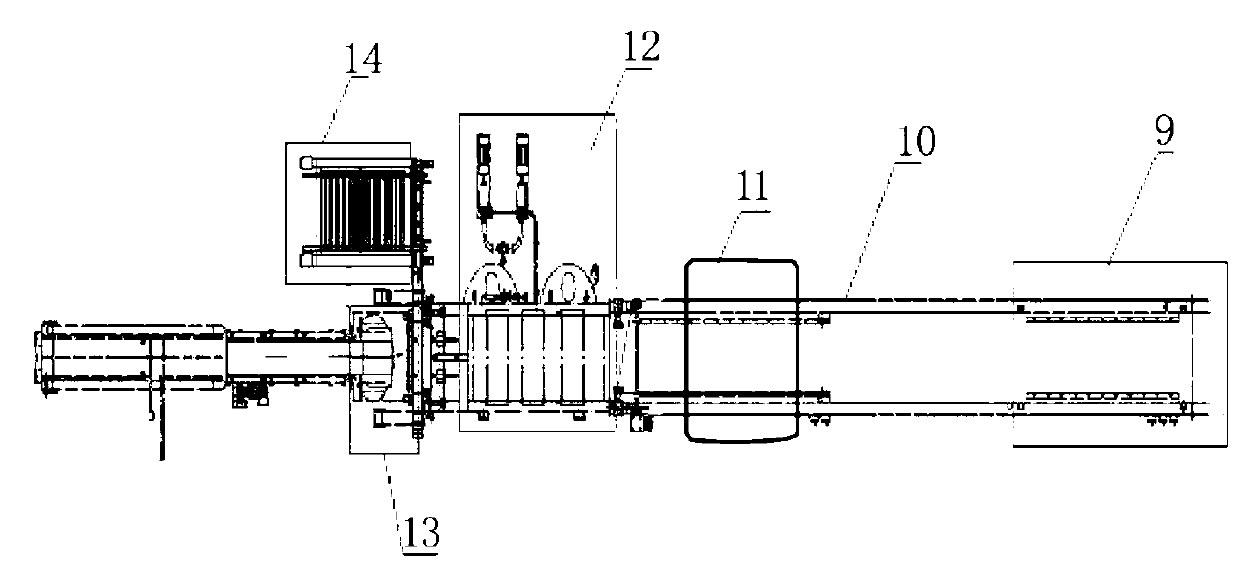

Copper electrolyte decoppering method by utilizing copper electrolytic residual anodes as cathodes and device thereof

InactiveCN103132101AReduce investmentPrevent burnoutPhotography auxillary processesProcess efficiency improvementElectrolytic agentCopper

The invention relates to a copper electrolyte decoppering method by utilizing copper electrolytic residual anodes as cathodes and a device thereof. The copper electrolyte decoppering method comprises the following steps of: driving a vehicle to lift the copper electrolytic residual anodes out of an electrolytic cell in an electrolytic plant and feed to a copper electrolytic residual anode washing unit with polar plate selecting function; controlling an indoor operating staff to select qualified copper electrolytic residual anode plates and feeding to a residual anode online open channel by the copper electrolytic residual anode washing unit with polar plate selecting function; transporting out after the qualified copper electrolytic residual anode plates are suspended and tightly arranged; feeding to a decoppering plant by a fork truck; placing in a decoppering electrolytic cell; and introducing direct current to carry out decoppering impurity removal on electrolyte. Through the application of the method and the device, a working procedure of manufacturing starting sheets is not required, the qualified residual anodes are selected by the copper electrolytic residual anode washing unit with polar plate selecting function, and the copper electrolytic residual anodes are utilized for placing the starting sheets as cathode plates in the working procedure of decoppering, so that the decoppering purpose is achieved, and the method is low in production cost, high in efficiency and good in decoppering effect.

Owner:广西有色再生金属有限公司

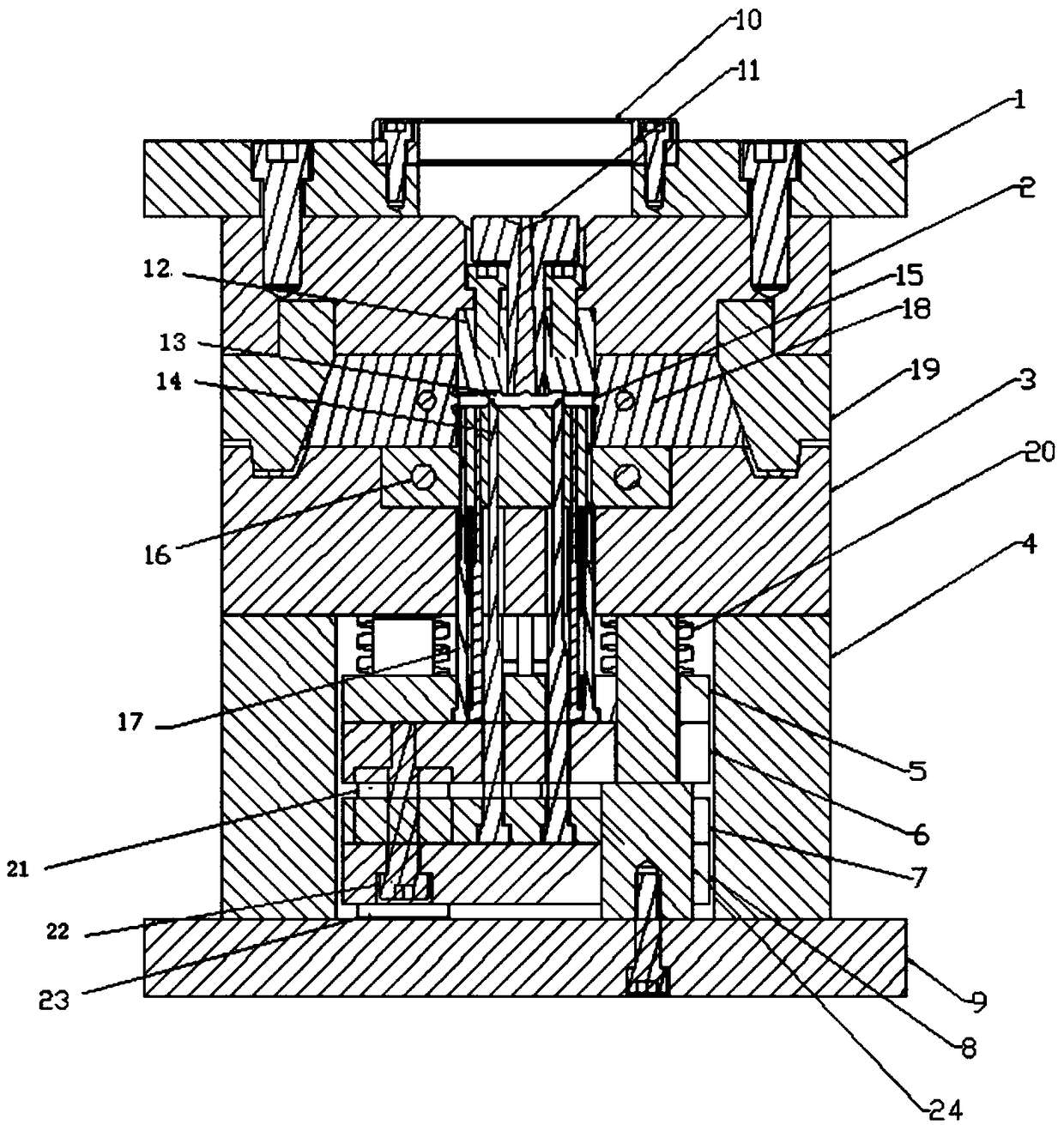

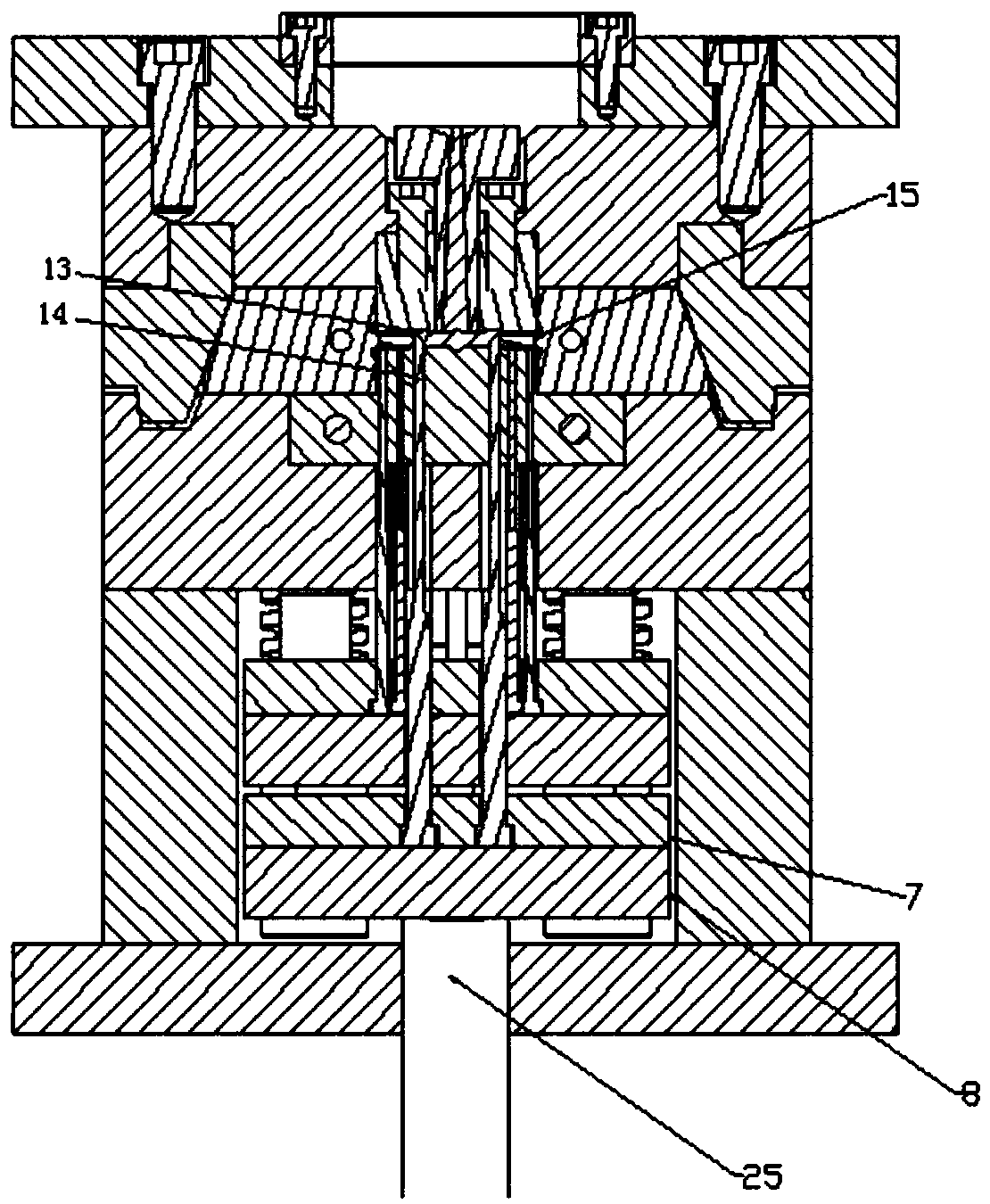

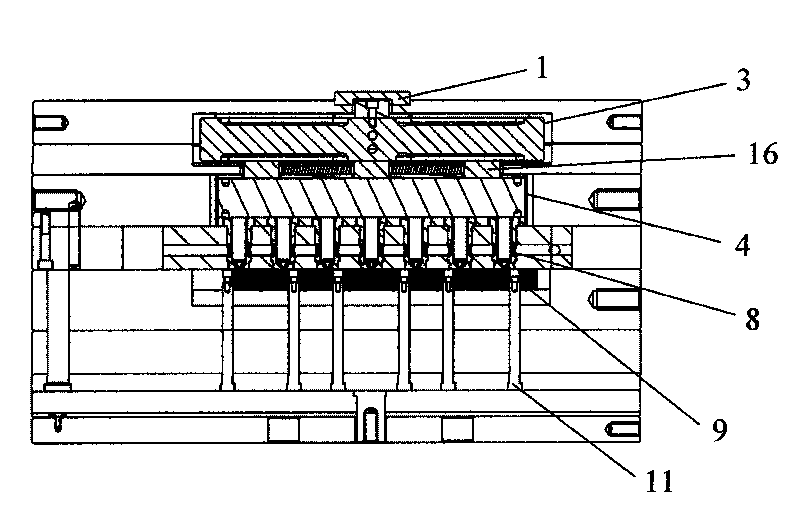

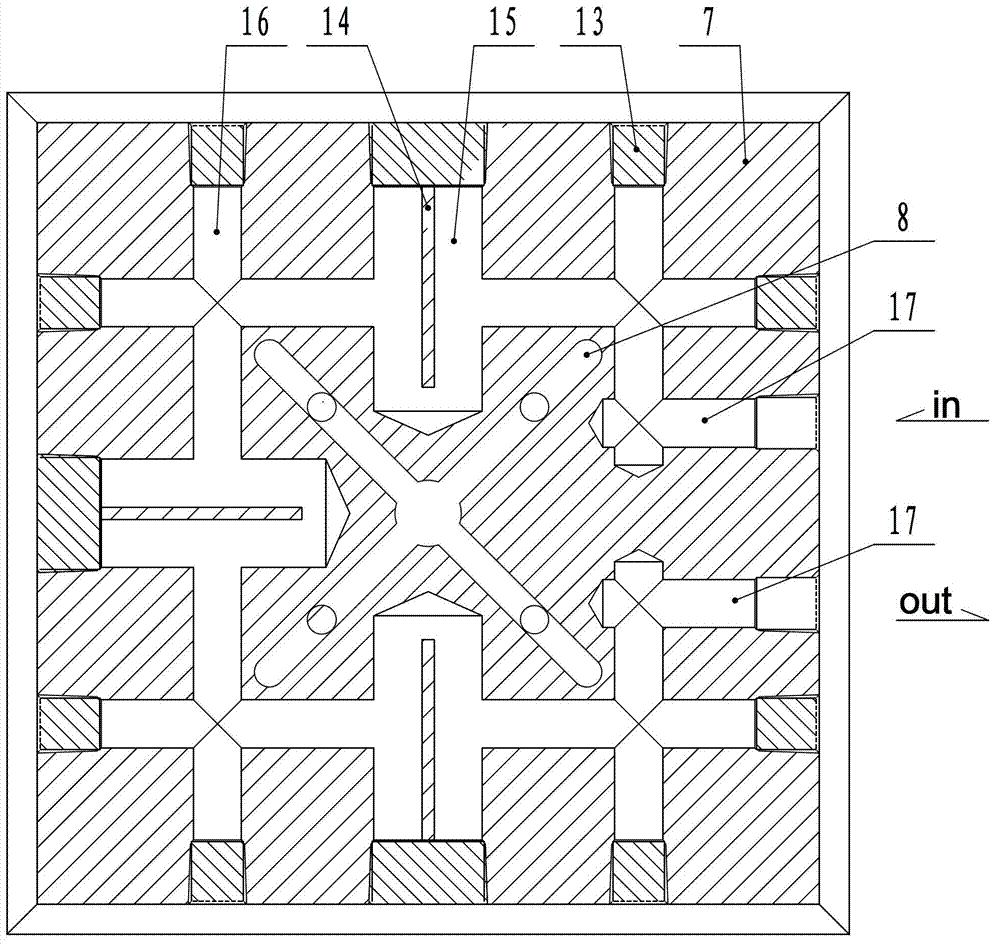

In-mould hot-cutting automatic sprue cutting mould structure

The invention discloses an in-mould hot-cutting automatic sprue cutting mould structure. The mould structure comprises a front mould, a rear mould and a cutting knife advancing assembly; the front mould and a rear mould are mutually assembled; the cutting knife advancing assembly is arranged in the rear mould; a flow channel (13) used for carrying out injection molding on a product (15) is formedbetween the front mould and the rear mould; the tail end of each sprue of the flow channel (13) is connected with a product injection moulding cavity; cutting knives (14) capable of advancing towardsthe sprues are arranged in the cutting knife advancing assembly; and in the injection moulding process, the cutting knife advancing assembly drives each cutting knife (14) in the rear mould to be jacked between each sprue of the flow channel (13) and each product injection moulding cavity, the sprues and the product injection moulding cavities are cut before the product is subjected to cooling moulding, and an in-mould hot-cutting technology of the product is achieved. The automation of in-mould hot-cutting moulding is achieved, unnecessary man-made movement in the production process is avoided, the quality conformance is ensured through completely-automatic mechanical shearing of the product, and the mould structure has the incomparable advantage compared with a traditional mould in the large-scale production process of the product.

Owner:上海宝鹿车业有限公司

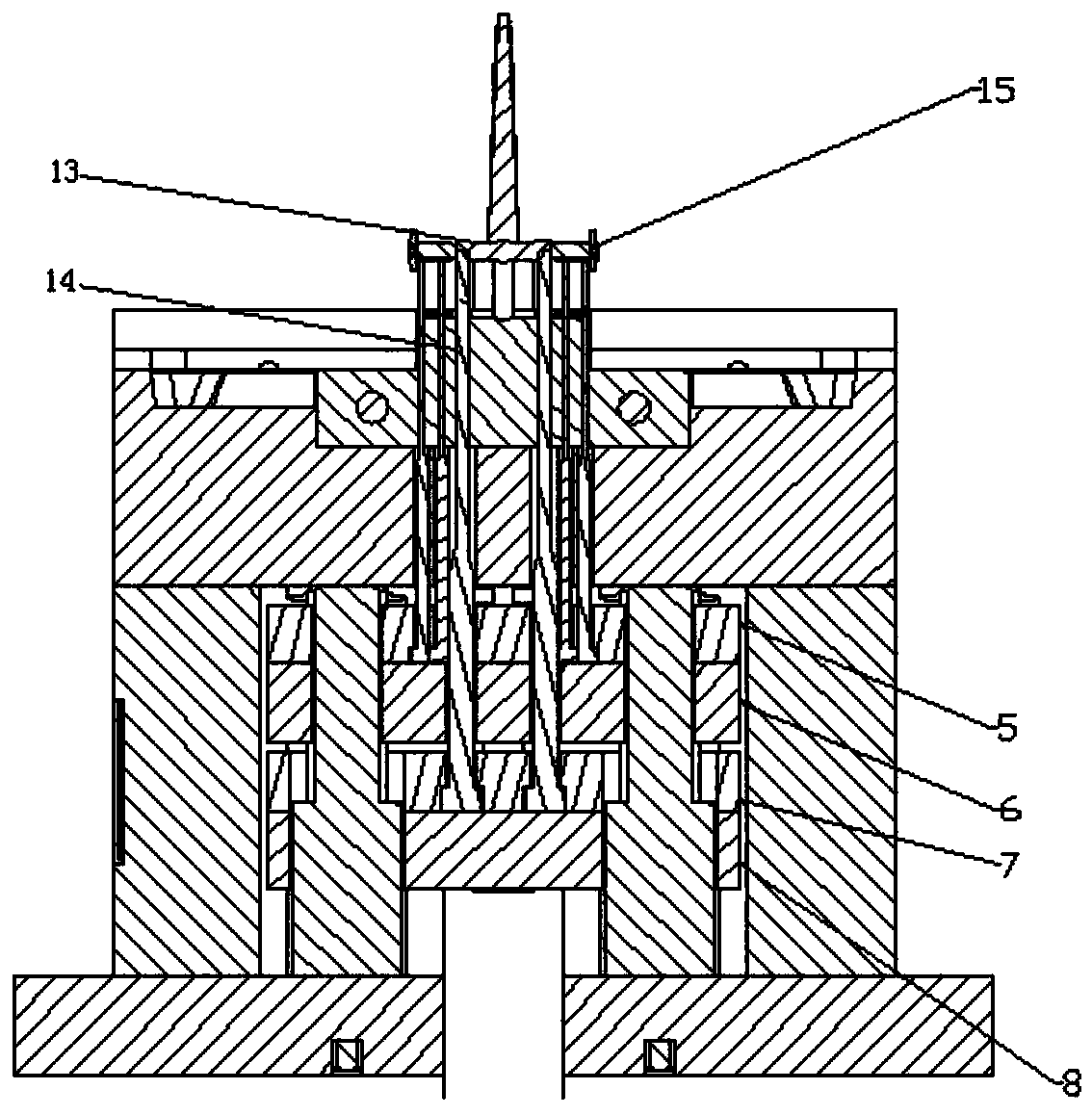

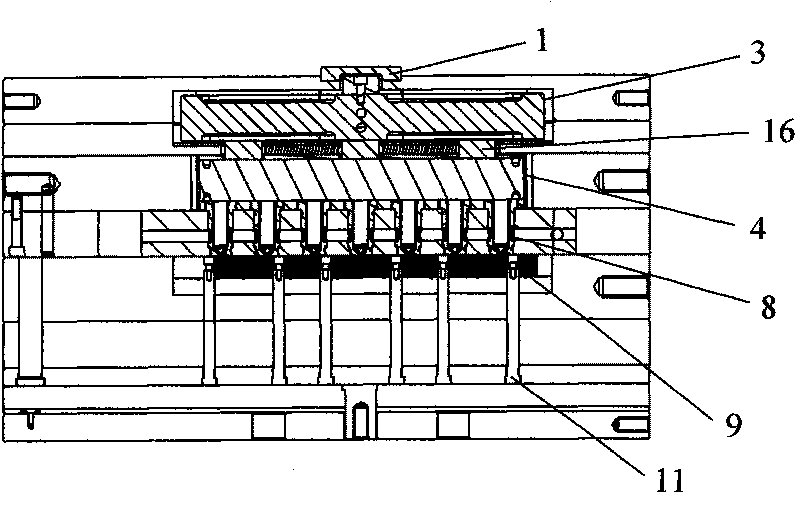

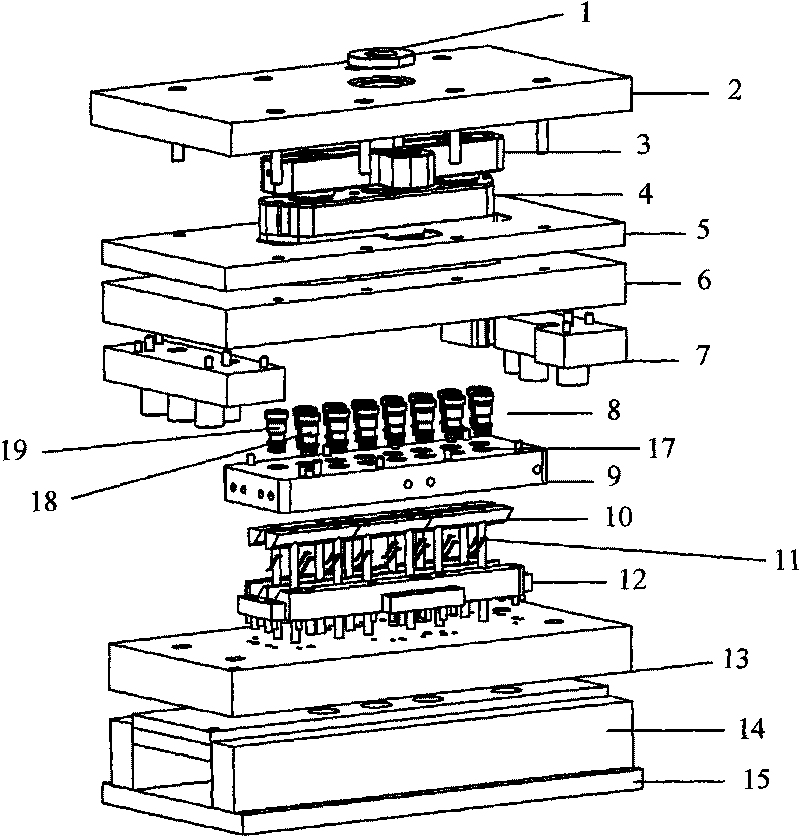

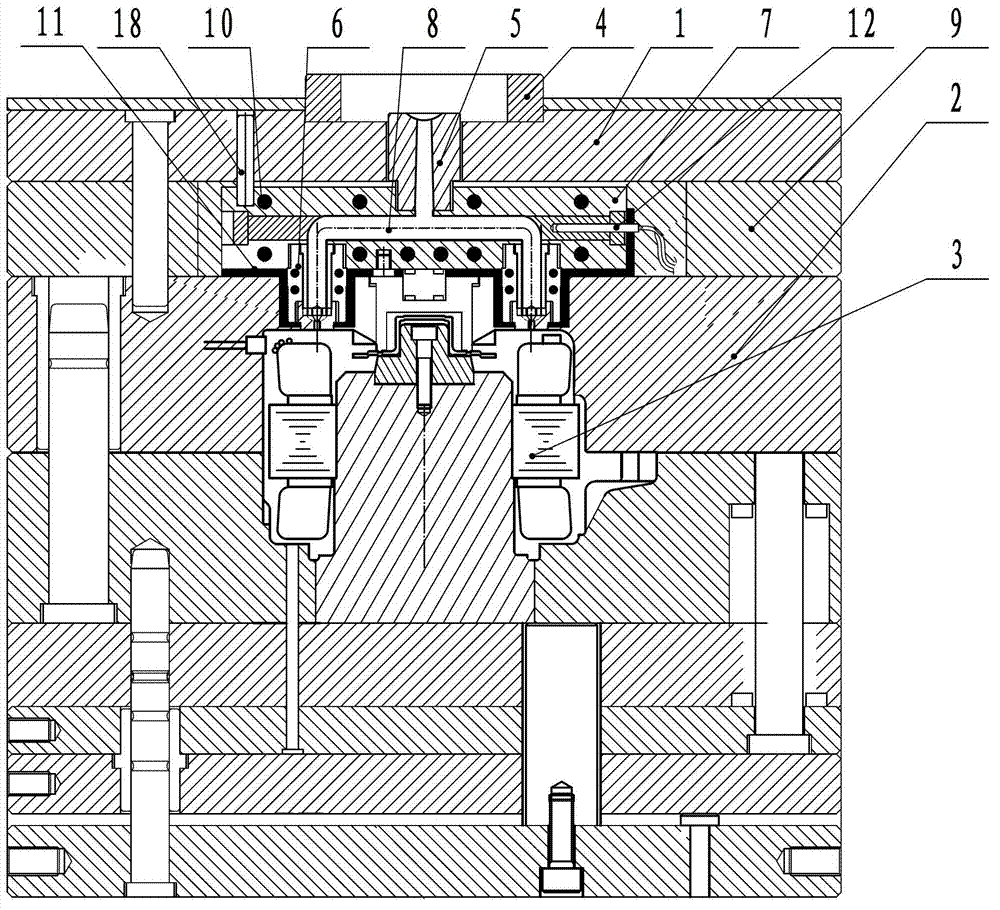

Layered hot runner mold

The invention relates to a layered hot runner mold, wherein runners in a shunting mechanism are communicated with runners in hot nozzles; the shunting mechanism consists of at least two layers of shunting plates and at least two layers of shunting nozzles; the two layers of shunting plates and the two layers of shunting nozzles are communicated with each other; the first layer of sprue bushings are arranged on the surface of a mold base panel; the number of the second layer of shunting nozzles is at least two, and the shunting nozzles are arranged between the two layers of shunting plates; the first layer of shunting plates and the second layer of shunting plates are respectively connected with the mold base panel and a hot runner subplate; both ends of each hot nozzle are respectively connected with a plate A and a front mold core, and at least four hot nozzles are arranged and sequentially arrayed. The layered hot runner mold has reasonable structural design and can carry out shunting operations on material solutions, carry out injection molding simultaneously through the hot nozzles, shorten the manufacturing and molding period, save plastic raw materials, reduce the waste, improve the production quality, eliminate subsequent working procedures and be beneficial to the production automation and the expansion of the application range of a molding process.

Owner:深圳市安高模具有限公司 +2

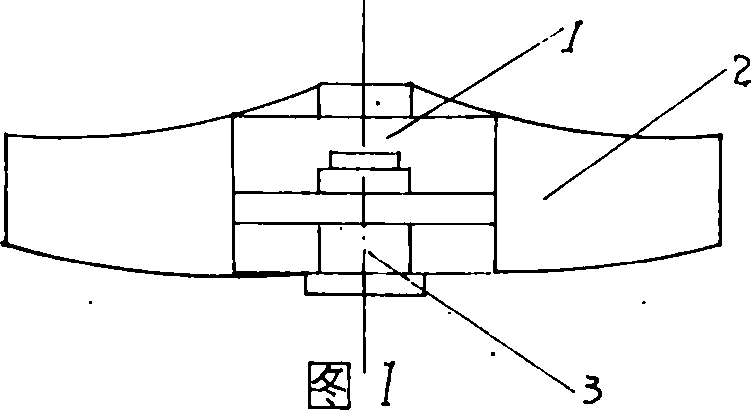

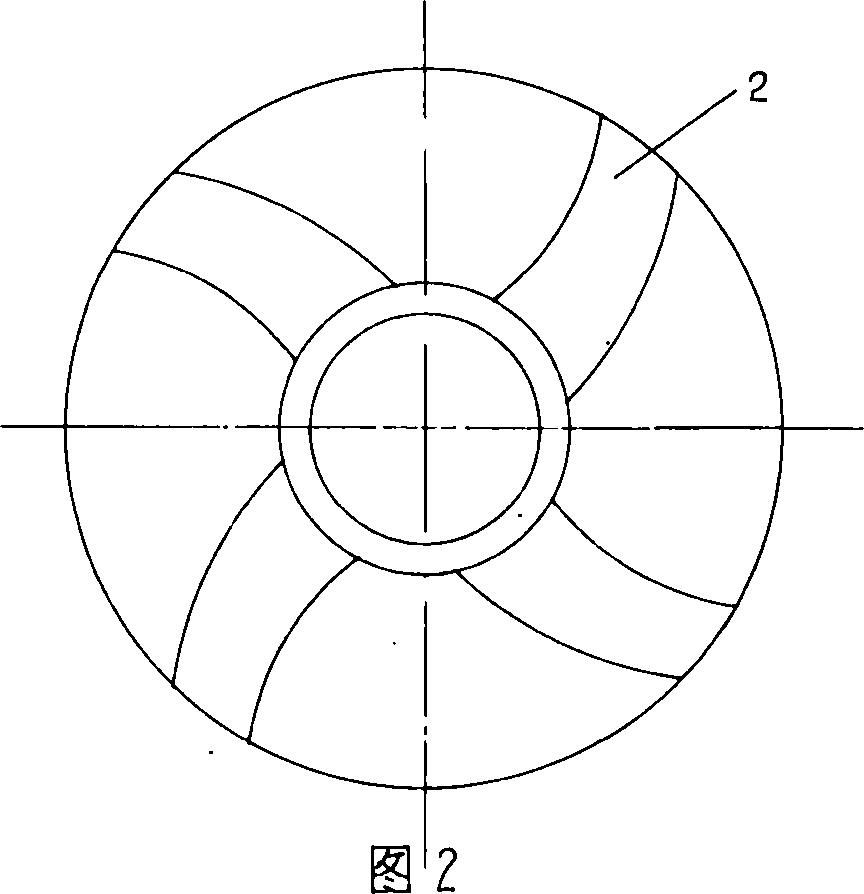

Die pressing plastic and steel fan impeller production process and special mould

The invention relates to a method for producing molded plastic steel fan blade wheel, and relative special mould, wherein it mainly comprises: producing integrated skeleton, producing base middle element, molding, and demoulding; the special mould comprises the upper and lower moulds and the overflow structure. The invention has the advantages that: it has high producing efficiency, high quality and high accuracy; the inventive blade wheel has light weight, high strength, high accuracy and stable operation.

Owner:张世忠

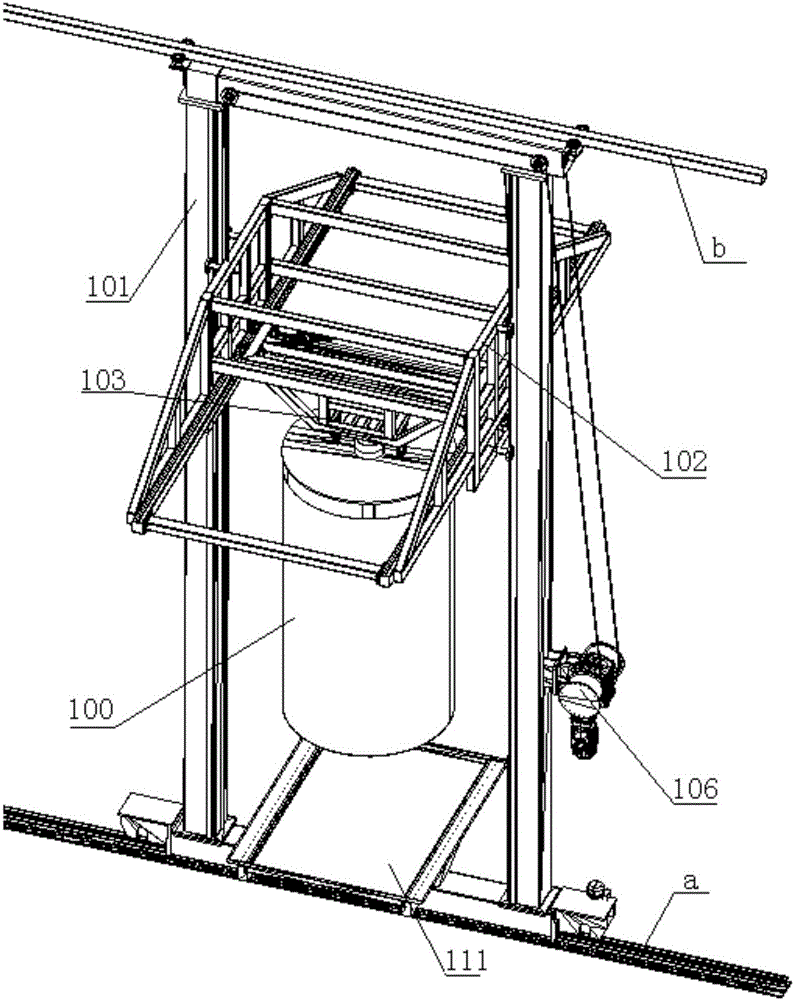

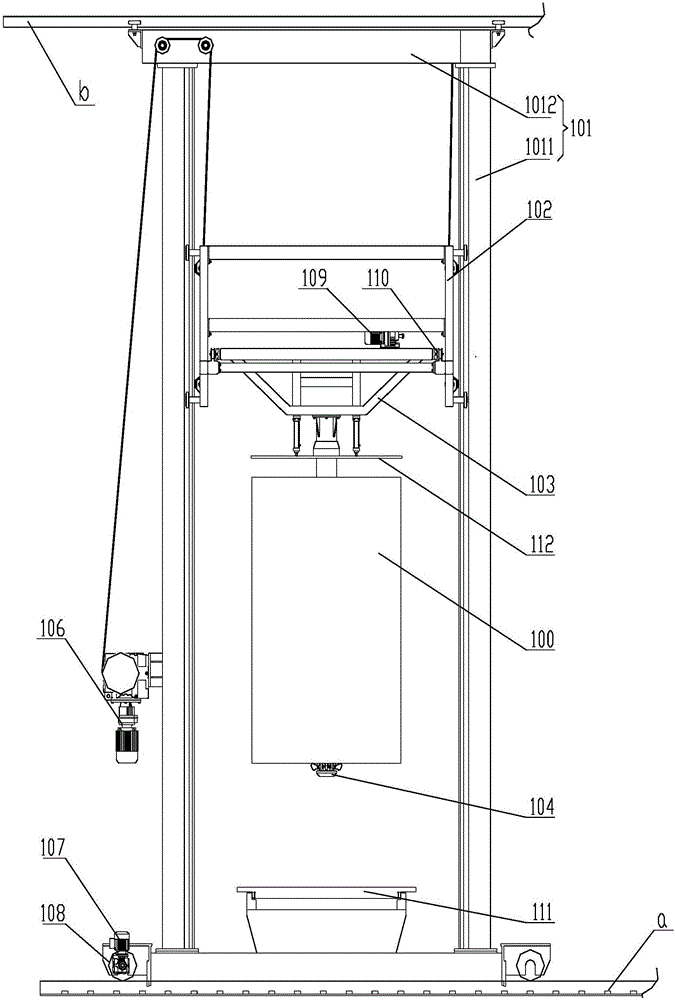

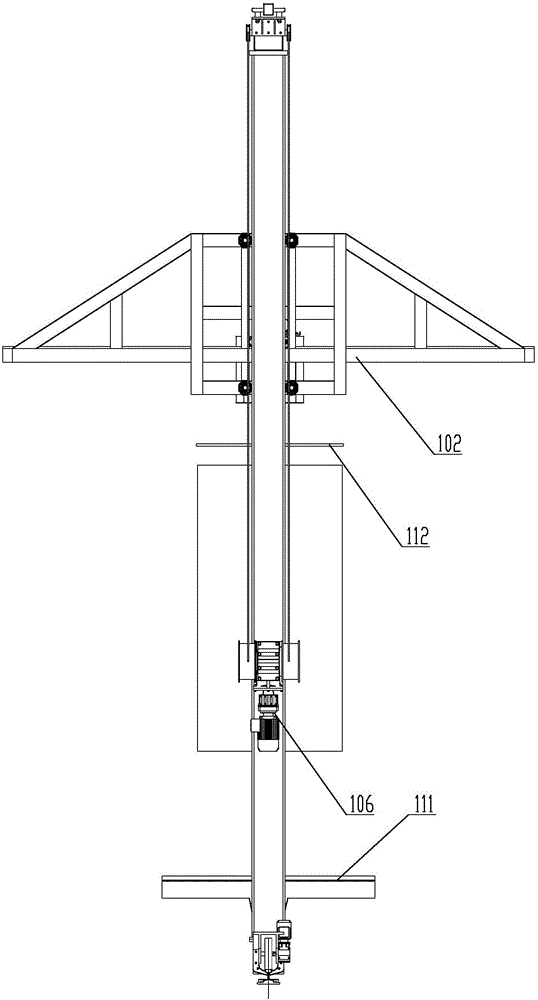

Medicine basket extracting machine and medicine basket extracting control system

ActiveCN106044575AReduce labor intensityImprove processing outputTrolley cranesLoad-engaging elementsControl systemProcess engineering

The invention discloses a machine basket extracting machine and a machine basket extracting control system. The medicine basket extracting machine comprises a main frame. The main frame is provided with an extracting device, a first drive device and a second drive device. The first drive device is used for driving the extracting device to relatively move relative to the main frame in the horizontal direction and the vertical direction. The extracting device is provided with an extracting part conducting grabbing in cooperation with a medicine basket set. The second driving device is used for driving the extracting part to act to enable the extracting part to be matched with the medicine basket set to be in a grabbing state, and the second driving device is used for driving the extracting par to act to enable the extracting part to be in a non-grabbing state. The medicine basket extracting machine can be used for extracting the medicine basket set from a traditional Chinese medicine extracting tank and conveying the medicine basket set to a next station, the labor intensity of workers is greatly lowered, the machining yield is increased, and automatic production and intelligent management are facilitated. In addition, the medicine basket set is extracted from the traditional Chinese medicine extracting tank through the mechanical equipment so that the traditional extracting quality can be ensured.

Owner:SHINVA MEDICAL INSTR CO LTD

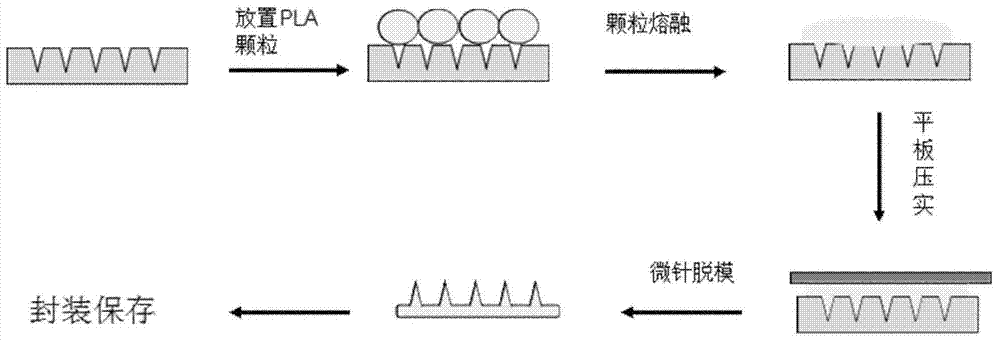

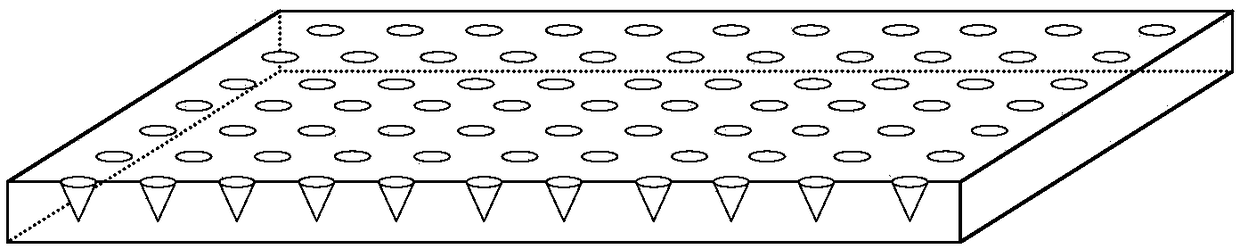

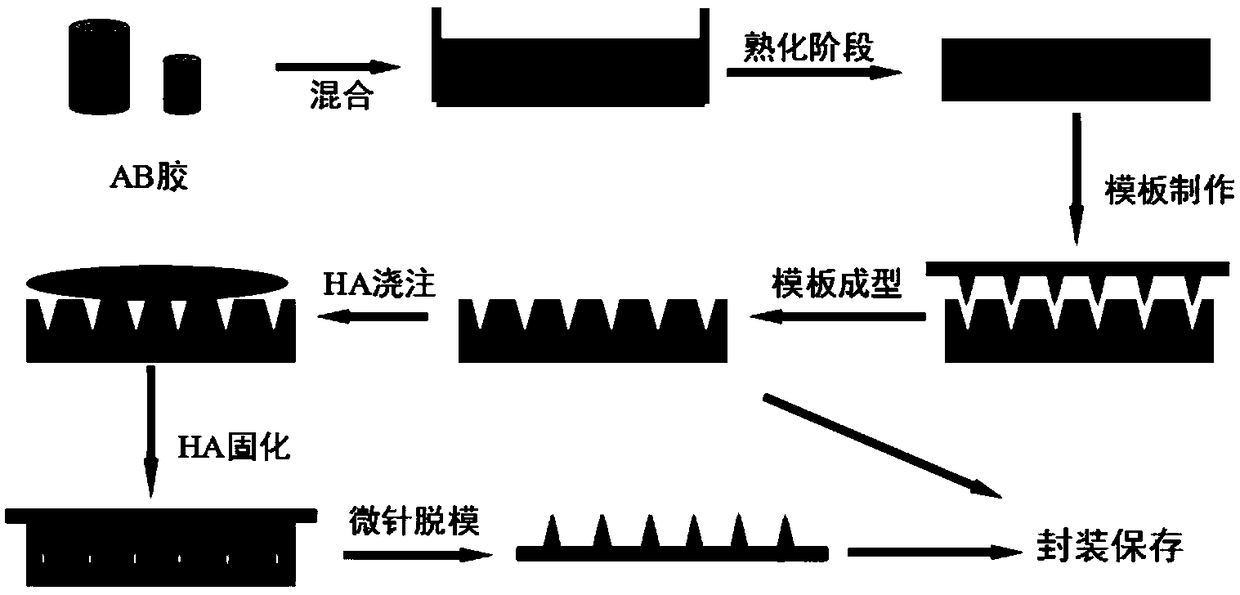

Microneedle template and preparation method and application thereof

InactiveCN109278219ANo physiological side effectsSingle production materialMicroneedlesMedical devicesState of artEpoxy

The invention relates to a microneedle template and a preparation method and application thereof and belongs to the technical field of dosage form equipment. The microneedle template is made from epoxy resin film. Micropore arrays are perpendicularly formed in the surface of the epoxy resin film. Micropores are in the shapes of inverted cones, and the tips of the cones face towards the inner sideof the film. Microneedle bodies are formed in the micropores in the preparation process of microneedles. Compared with the prior art, the microneedle template is good in micropore uniformity, tenacious, durable, and capable of being used for preparation of biologically-soluble microneedles in the medicine and beauty fields, and in addition, the prepared microneedles can be used for transdermal drug delivery or transdermal treatment; the microneedle template is simplex in manufacturing material, simple in technology and convenient to solidify, automatic defoaming can be achieved when the microneedle template is used in cooperation with a curing agent, demoulding is easy, the preparation efficiency is high, and production automation is easy to achieve; and the template is low in performanceshrinkage and stable in chemical property, and the cost is much lower compared with the prior art in the market.

Owner:DALIAN UNIV OF TECH

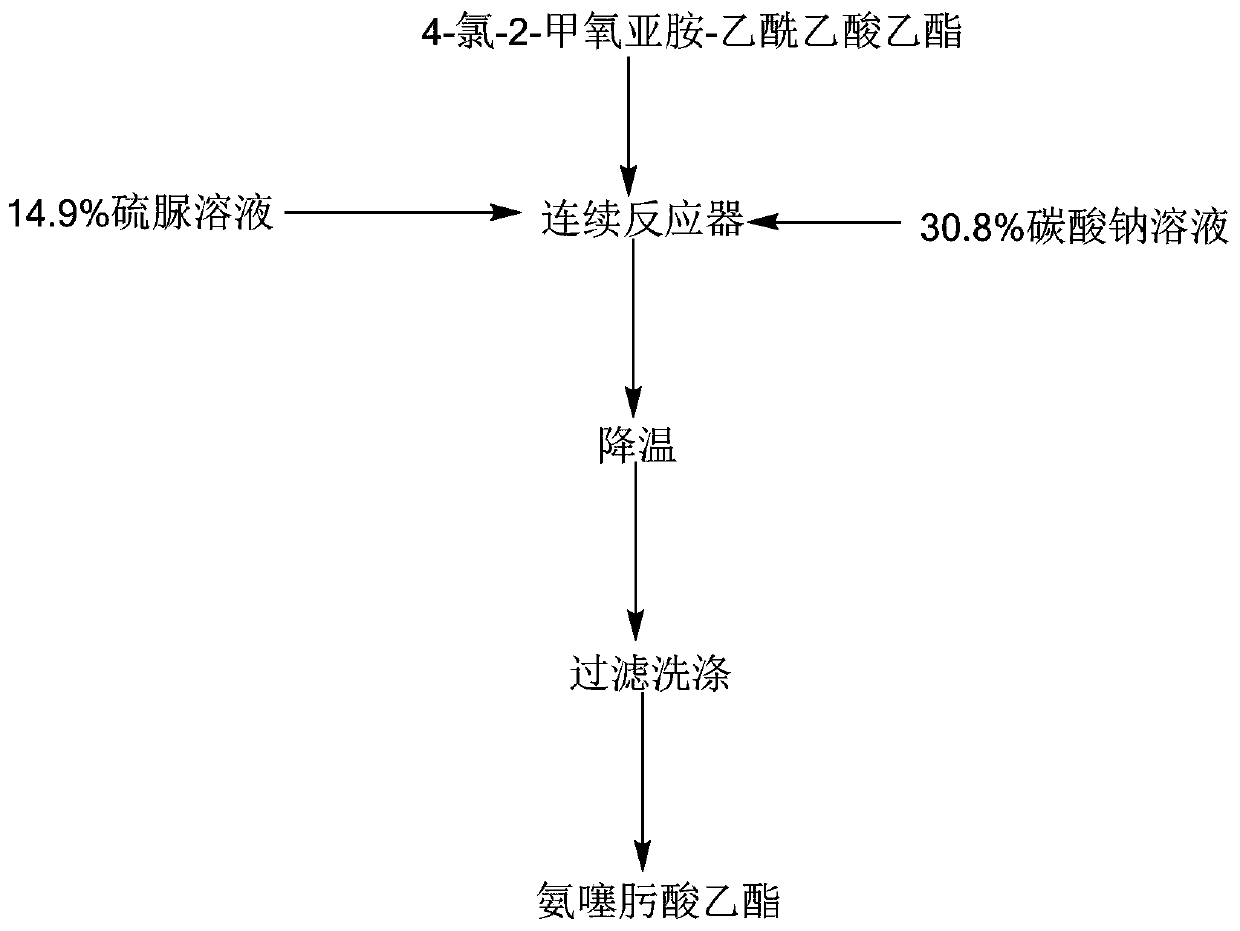

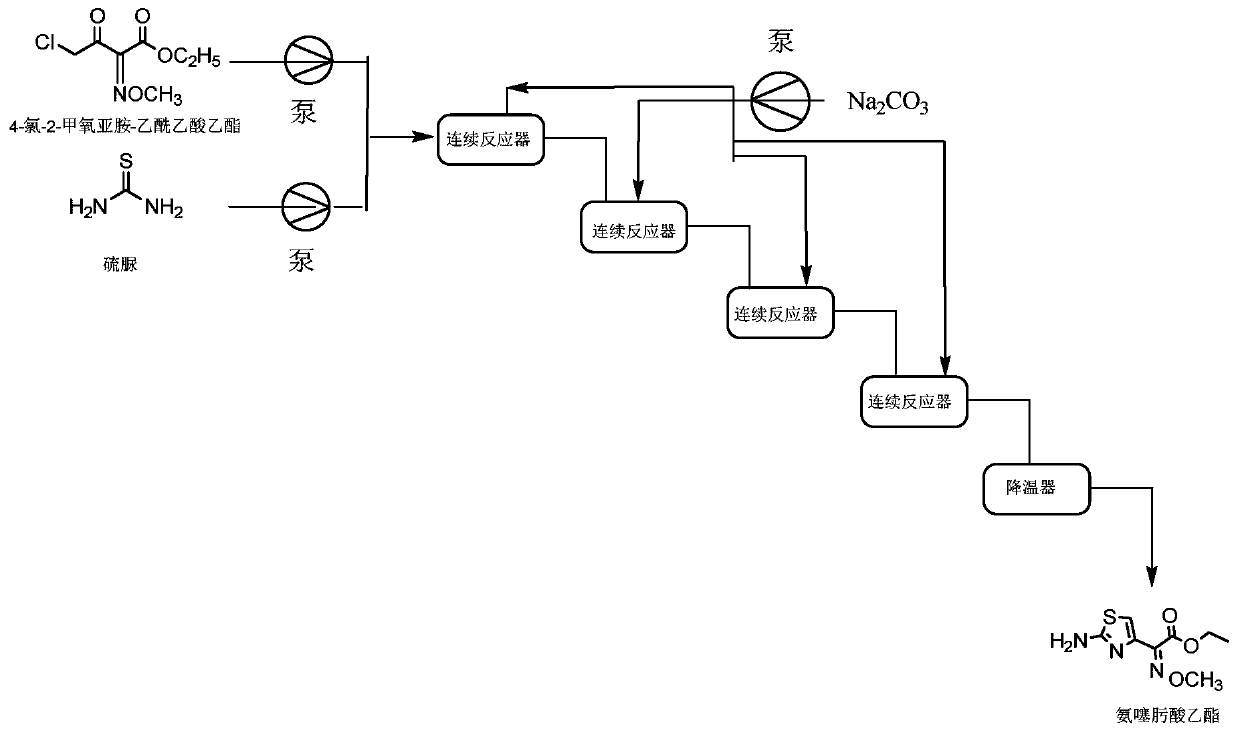

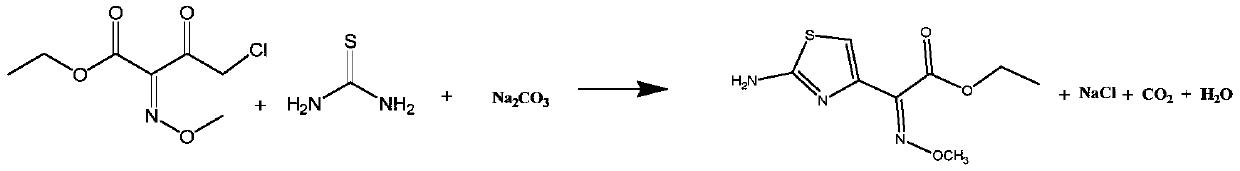

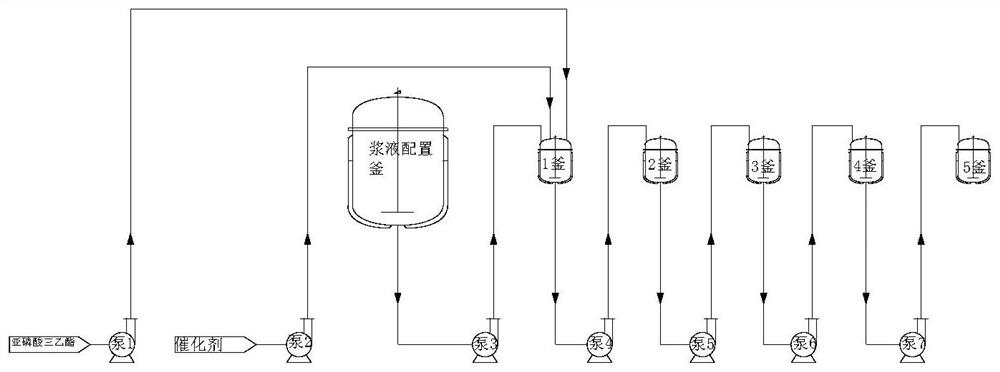

Method for continuously synthesizing ethyl 2-(2-aminothiazole-4-yl)-2-methoxyiminoacetate

The invention discloses a method for continuously synthesizing ethyl 2-(2-aminothiazole-4-yl)-2-methoxyiminoacetate, and belongs to the field of cephalosporin medicine synthesis. According to the method, a continuous reaction device is utilized, 4-chloro-2-methoxyimino ethyl acetoacetate reaction liquid and a thiourea solution are added into a reactor according to a certain proportion, a certain temperature is kept, a soda ash solution is used for adjusting the pH value, the reaction liquid overflows to a cooler to be cooled, a product is obtained after filtering and washing, the liquid phasepurity is larger than 99.5%, and the yield is 85%-93%. The method has the advantages that the synthesis of ethyl 2-(2-aminothiazole-4-yl)-2-methoxyiminoacetate realizes continuous reaction, the variable control in the reaction process is more efficient and timely, the product quality stability is obviously improved, and meanwhile, as the continuous reaction is realized, the heat in the reaction process is effectively controlled, the energy can be effectively saved, the production cost is reduced, and the method is suitable for industrial large-scale production.

Owner:APELOA PHARM CO LTD +1

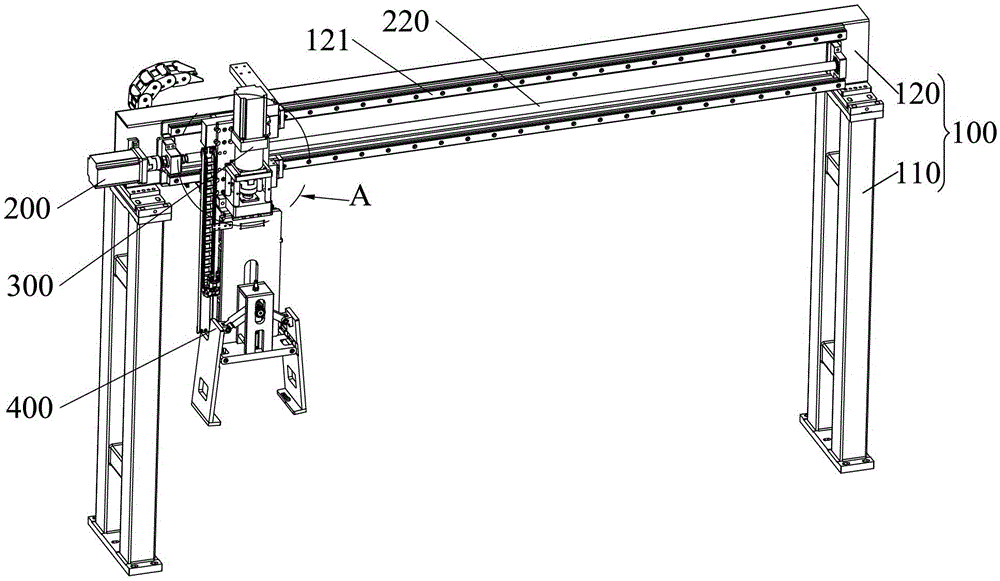

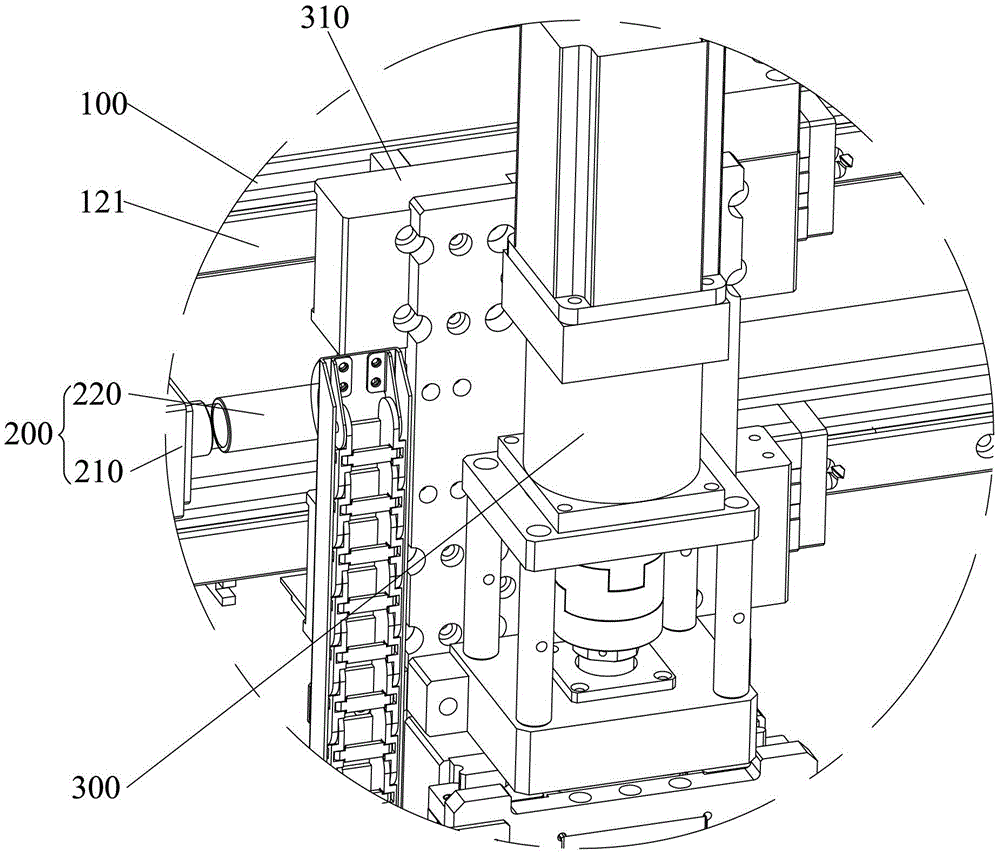

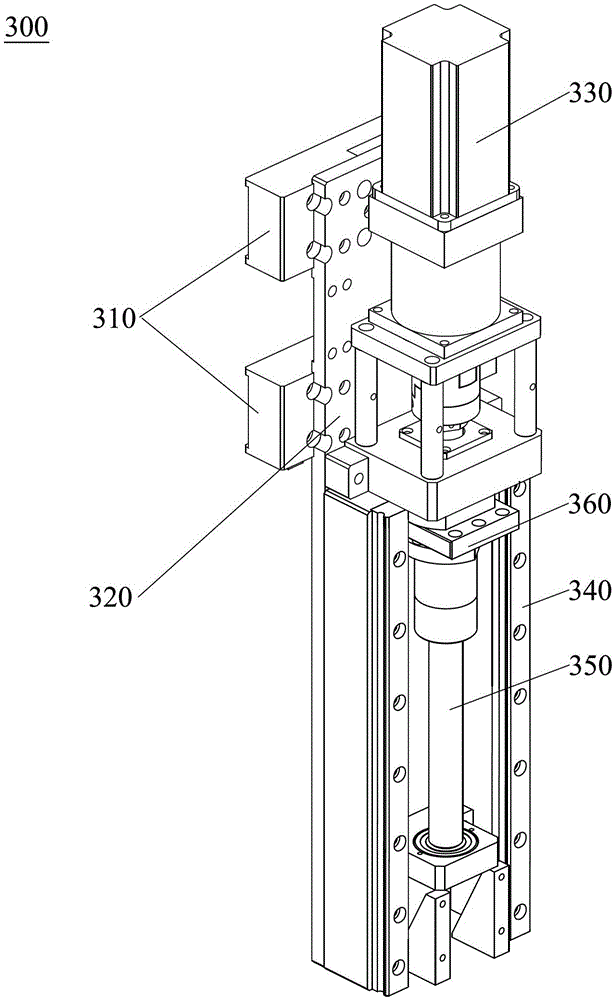

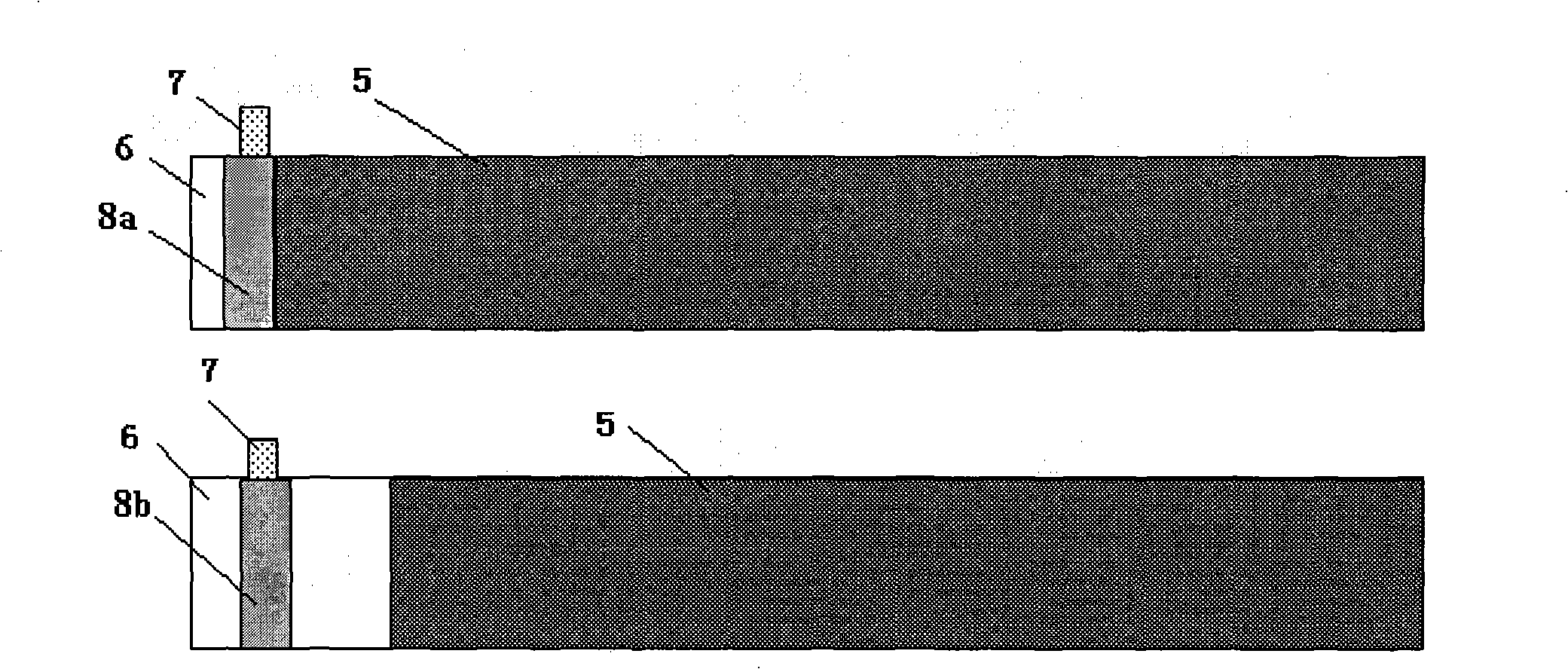

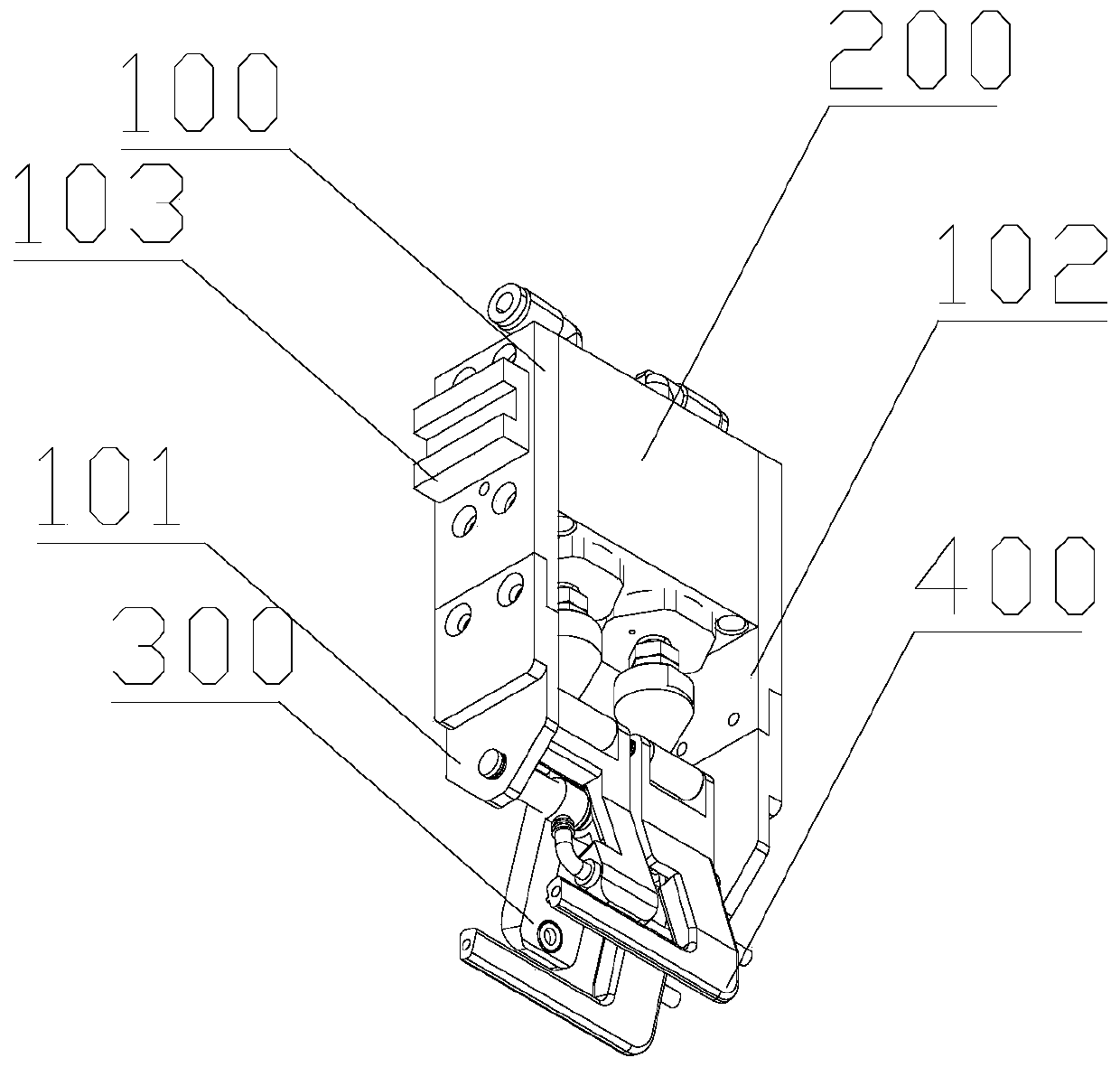

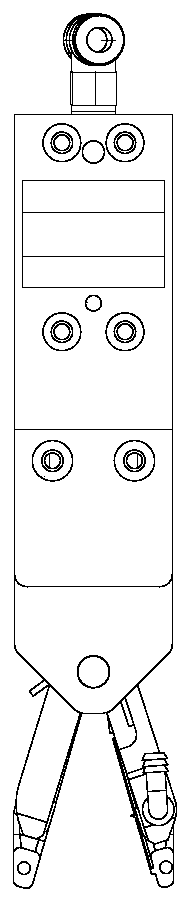

Mechanical arm

ActiveCN103213120BImprove qualityEasy to moveProgramme-controlled manipulatorGripping headsRobotic armEngineering

The invention relates to battery production equipment, in particular to a mechanical arm for carrying battery clamps. The mechanical arm comprises a support, a horizontal driving mechanism, a vertical driving mechanism and a clamping mechanism, wherein the vertical driving mechanism is installed on the support in a horizontally-sliding mode, and the horizontal driving mechanism is installed on the support and drives the vertical driving mechanism to horizontally move; the vertical driving mechanism drives the clamping mechanism to move up and down; the clamping mechanism comprises a bearing plate, a pushing unit and at least two jaws, and the bearing plate is connected with the output end of the vertical driving mechanism; and the pushing unit is arranged on the bearing plate and pushes the two jaws to be opened or closed. The mechanical arm is used for carrying the battery clamps so as to replace manual carrying, so that the production efficiency is increased, the battery quality is optimized, and the production automation is benefited.

Owner:DONGGUAN TEC RICH ENGINEERING CO LTD

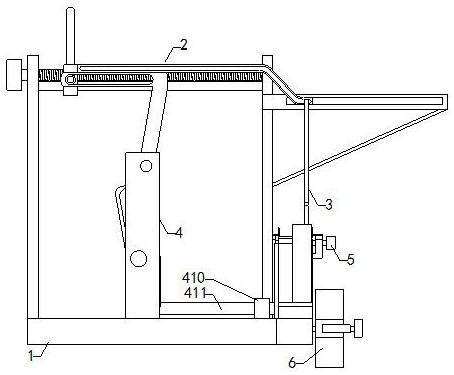

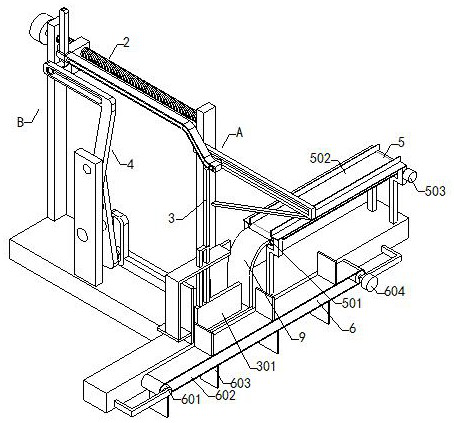

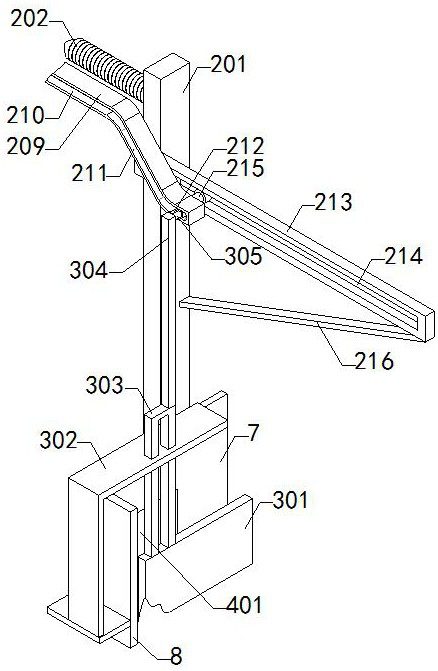

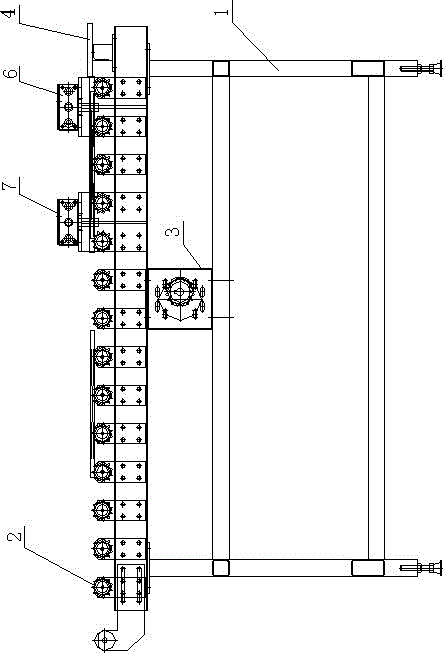

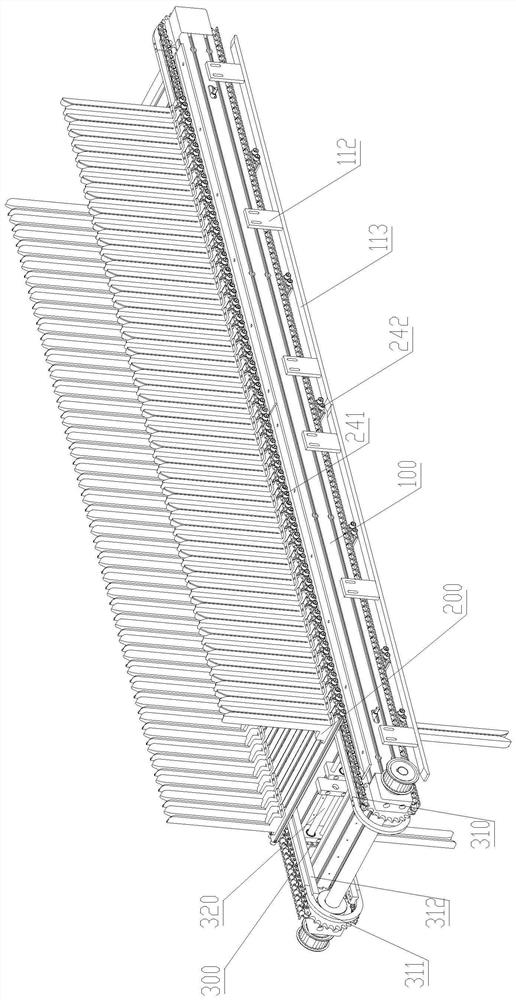

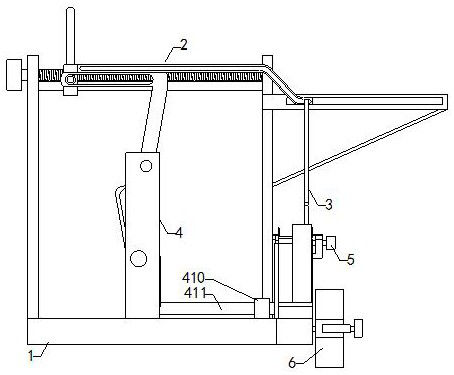

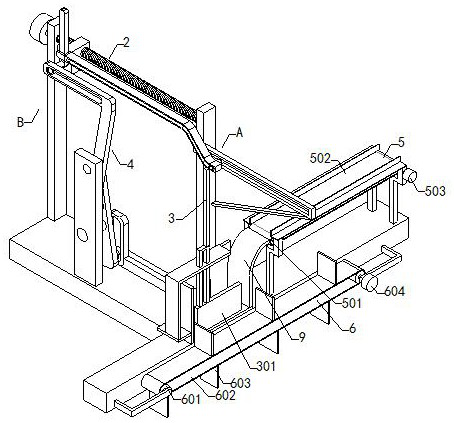

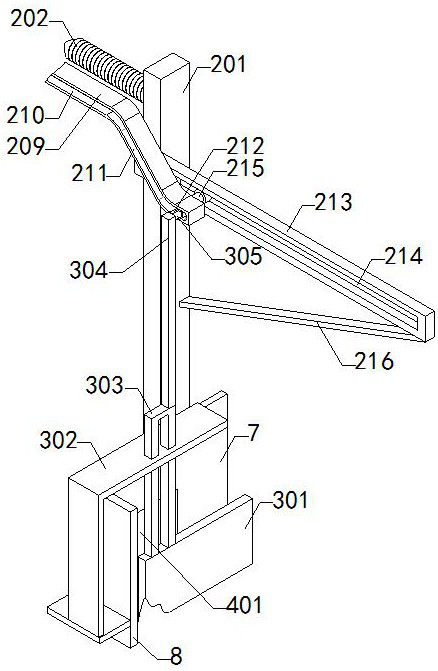

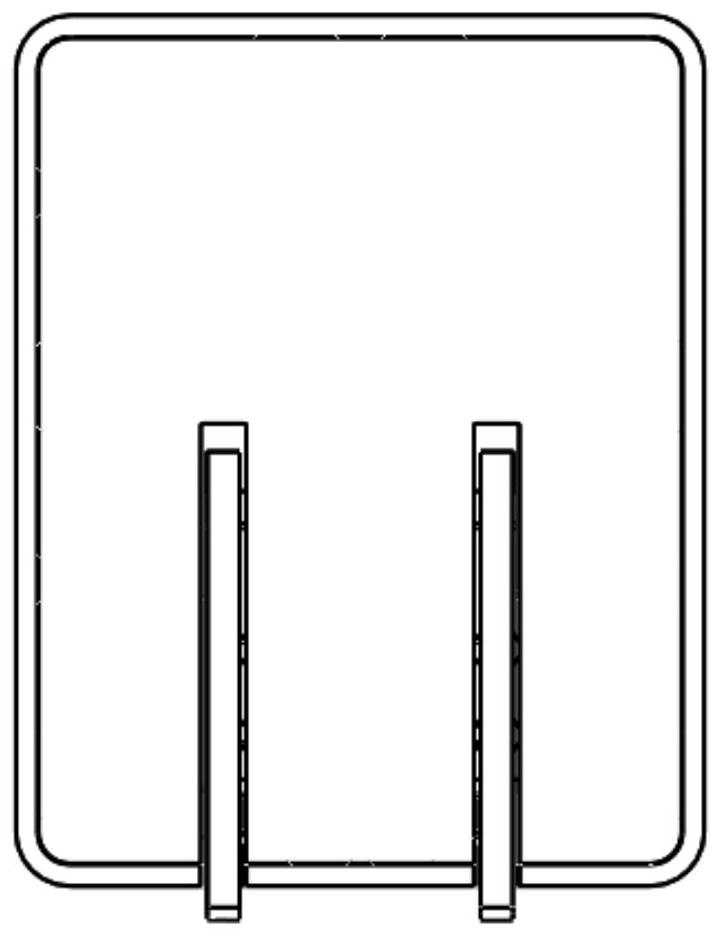

Intelligent card arranging and collecting equipment

ActiveCN113184272AGuaranteed uptimeFacilitate production automationPaper article packagingControl engineeringSmart card

The invention relates to the technical field of intelligent card accessory devices, in particular to intelligent card arranging and collecting equipment. The intelligent card arranging and collecting equipment is simple in structure; and after cards are stacked, the cards can be automatically pushed to a downstream conveyor belt, so that the operation steps of operators are reduced, automatic production is facilitated, and the working efficiency is improved. The intelligent card arranging and collecting equipment comprises a base station serving as a base body of the whole device, wherein a driving mechanism, a lifting mechanism, a discharging mechanism, an upstream conveyor belt and a downstream conveyor belt are arranged on the base station; the whole base station is in a T shape; an L-shaped frame body is installed on the base station; a limiting plate is installed at one side of the frame body; a guide plate is installed at one side, opposite to the limiting plate, of the frame body; the driving mechanism is used for driving the lifting mechanism and the discharging mechanism to act; the output end of the lifting mechanism is provided with a baffle, and the lifting mechanism is used for lifting the baffle, so as not to hinder the movement of the cards; a push plate is arranged at the output end of the discharging mechanism; and the discharging mechanism is used for pushing the cards to the downstream conveyor belt.

Owner:SHENZHEN YUANMINGJIE TECH

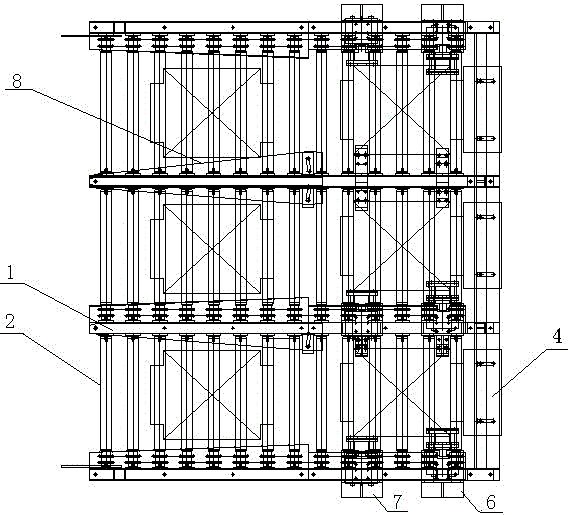

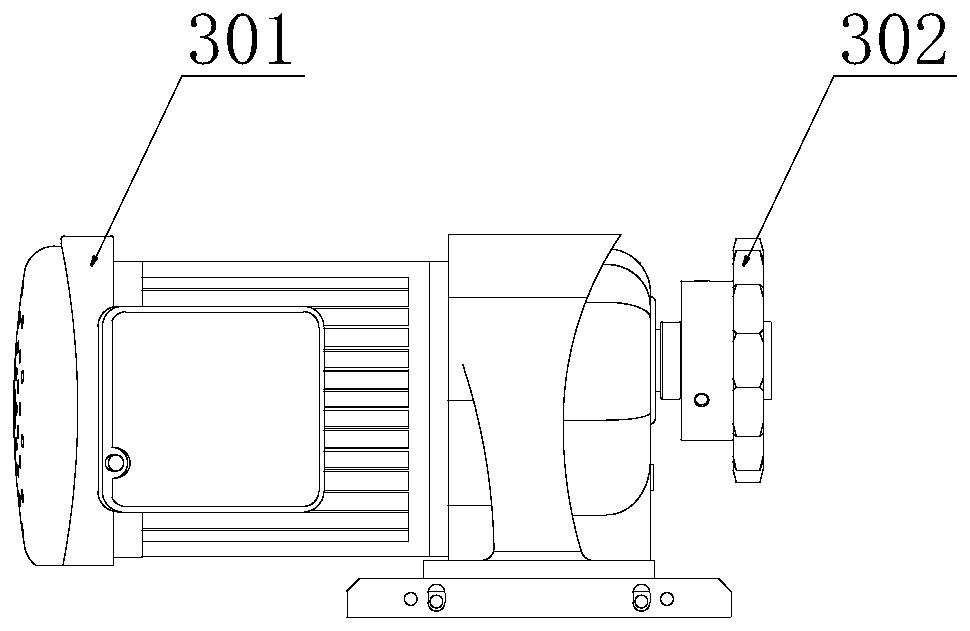

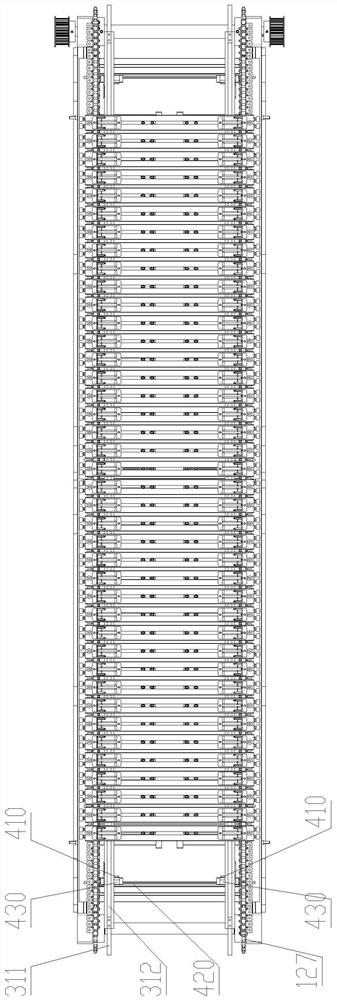

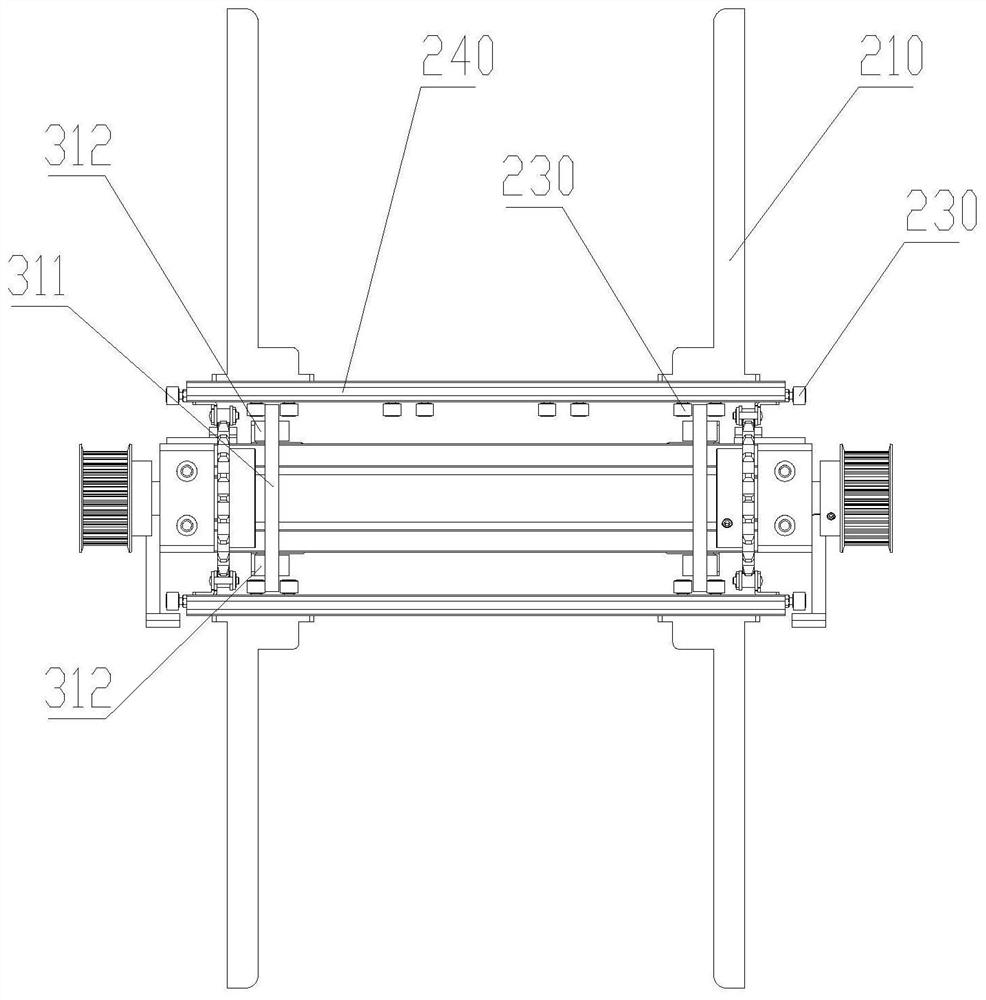

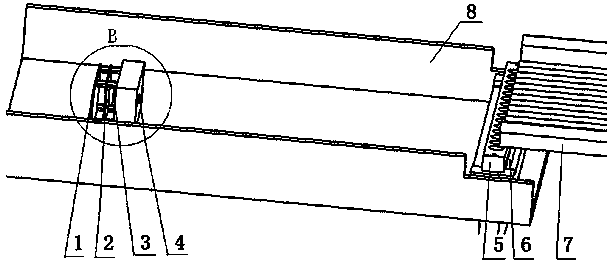

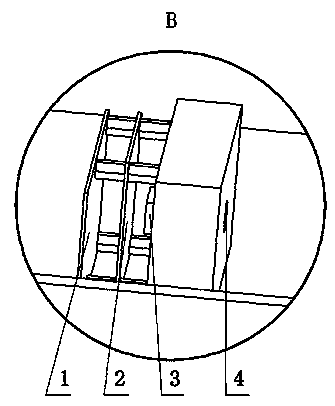

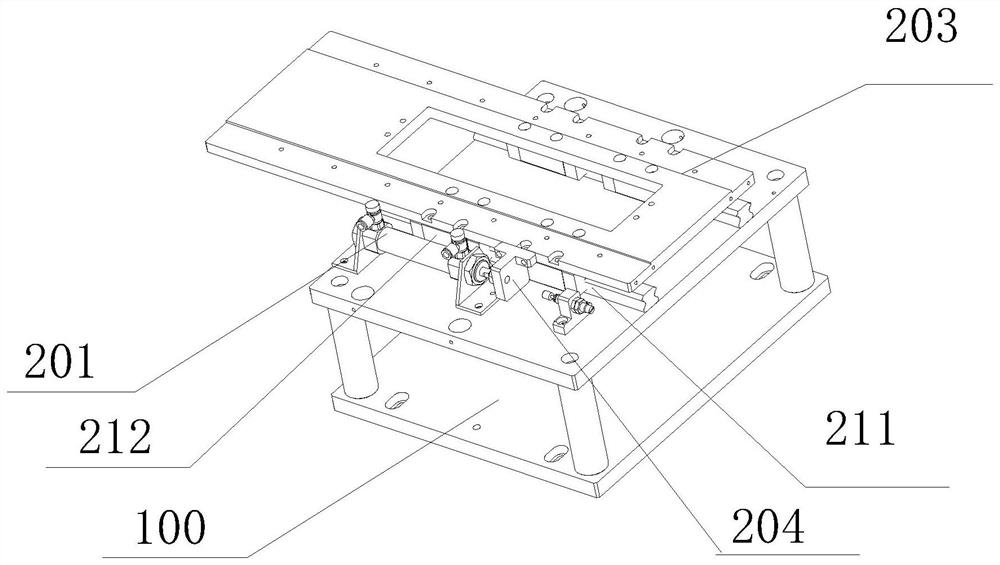

Multi-station automatic positioning device for oven material conveying

InactiveCN105083938APrecise positioningImprove efficiencyConveyor partsEngineeringMechanical engineering

A multi-station automatic positioning device for oven material conveying comprises a rack, and at least one automatic material conveying positioning device body is arranged on the rack. Each automatic material conveying positioning device body comprises a conveying unit and an automatic positioning unit, and the conveying unit extends to the automatic positioning unit in the conveying direction; each conveying unit comprises rollers and a motor, the rollers are fixedly arranged on the rack in sequence, the motor is arranged on one side of the rack and below the rollers, and the motor is connected with the rollers through a chain; each automatic positioning unit comprises a positioning block, a sensor, a front positioning cylinder and a rear positioning cylinder, the front positioning cylinder and the rear positioning cylinder are arranged on the same side of the rollers, and the sensor is arranged on the other sides of the rollers; and the sensors are connected with the front positioning cylinders, the rear positioning cylinders and the motors, the positioning blocks are arranged on the right sides of the front positioning cylinders, and the positioning blocks are higher than the rollers. By means of the multi-station automatic positioning device for oven material conveying, multi-station automatic positioning for oven material conveying can be achieved, the production efficiency is improved, the production cost is reduced, and the multi-station automatic positioning device for oven material conveying is suitable for popularization.

Owner:SUQIAN PENGHUI MACHINERY CO LTD

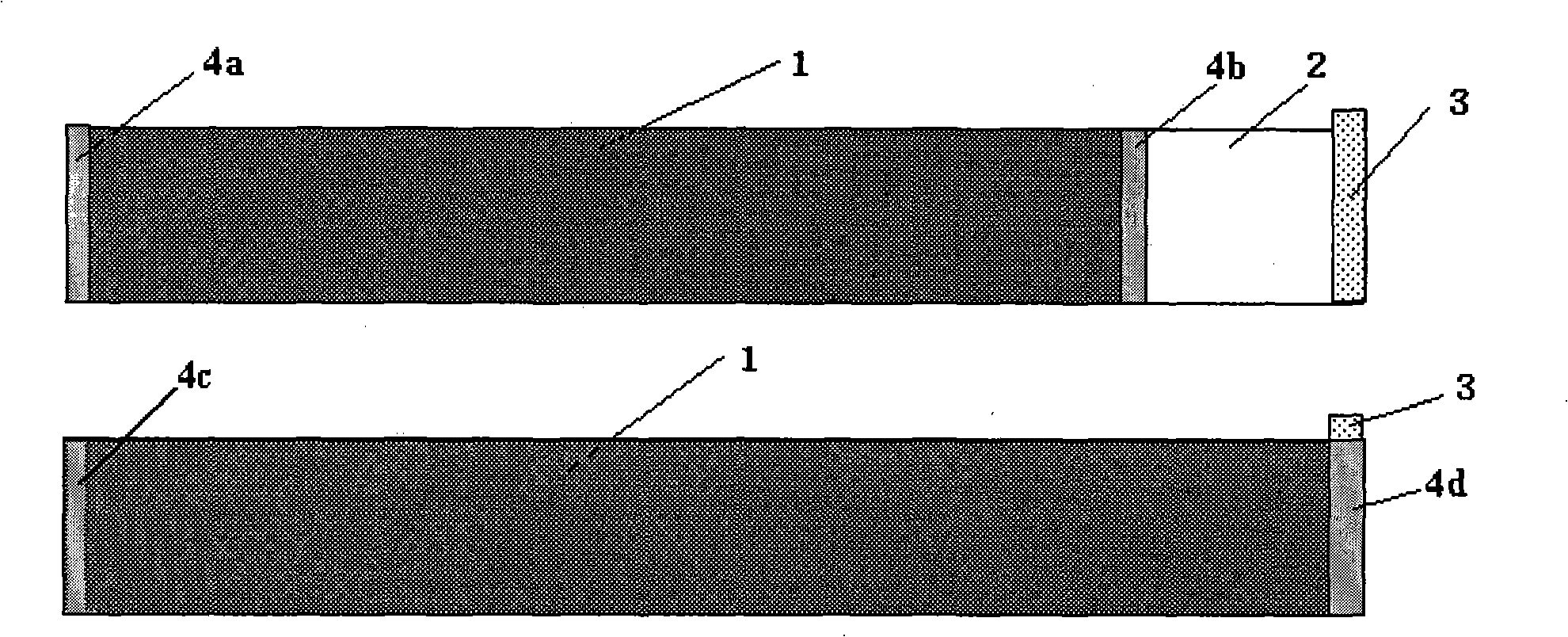

Lithium ion battery and preparation method thereof

ActiveCN101867070BThe problem of losing viscosity failure will not existImprove high temperature resistanceElectrode manufacturing processesFinal product manufactureEngineeringLithium-ion battery

The invention provides a lithium ion battery and a preparation method thereof. Insulating coating layers are arranged in at least the following areas of the battery: 1. an area which is on the other surface of a positive plate and corresponds to an area in which a positive pole tab is jointed with a positive pole current collector; and 2. an area which is on the other surface of a negative pole tab and corresponds to an area in which the negative pole tab is jointed with a negative pole current collector, and an area which is on the other surface of a negative plate and corresponds to an areain which the negative pole tab is jointed with the negative pole current collector. Through using the insulating coating layers to substitute for adhesive tapes, the invention has the advantages thatthe high-temperature safety of the battery is improved, and the initial capacity of the battery can be improved because the insulating coating layers have certain ability of passing lithium ions.

Owner:BYD CO LTD

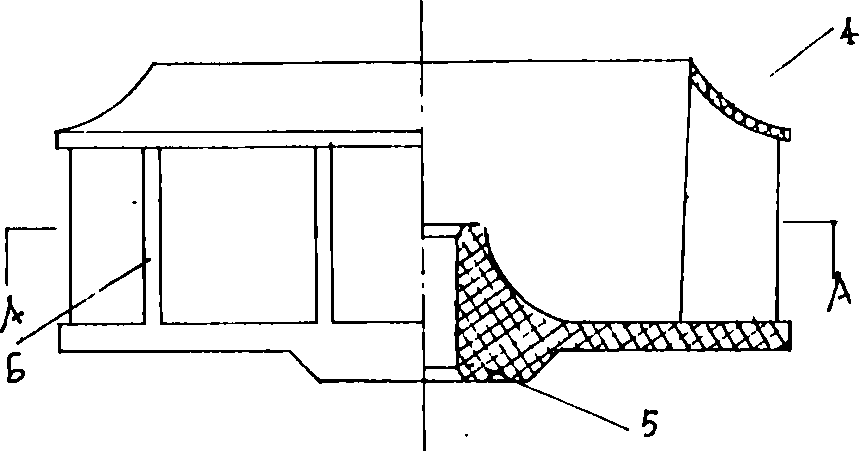

Plastic package stator runner-free mold

The invention provides a plastic package stator runner-free mold, and relates to a mold. In the prior art, the BMC plastic package stator and a material handle are integrated after injection molding, such that a special device is required to cut the material handle, finishing is performed, and disadvantages of more processes, time wasting, appearance affecting, environmental pollution and poor plastic package part quality are provided. The plastic package stator runner-free mold is characterized in that a middle position of a mold fixation seat plate is provided with a positioning ring and a main pouring nozzle concentrically arranged with the positioning ring, a mold fixation plate is provided with a material inlet chamber having an upward opening, a cold pouring nozzle is embedded into the material inlet chamber, a runner plate is arranged between the mold fixation seat plate and the mold fixation plate, a cold runner penetrating the main pouring nozzle and the cold pouring nozzle is arranged inside the runner plate, both sides of the runner plate are provided with a supporting foot higher than the runner plate, the runner plate and the cold pouring nozzle are provided with cooling channels, and thermal insulation layers are arranged between the cold pouring nozzle and the chamber wall of the material inlet chamber and between the runner plate and the mold fixation plate. According to the present invention, the BMC material always maintains an uncured flowing state in the runner plate, and no flowing water material is generated during an injection molding process so as to achieve material saving, energy consumption reduction and environment protection.

Owner:WOLONG ELECTRIC GRP CO LTD +1

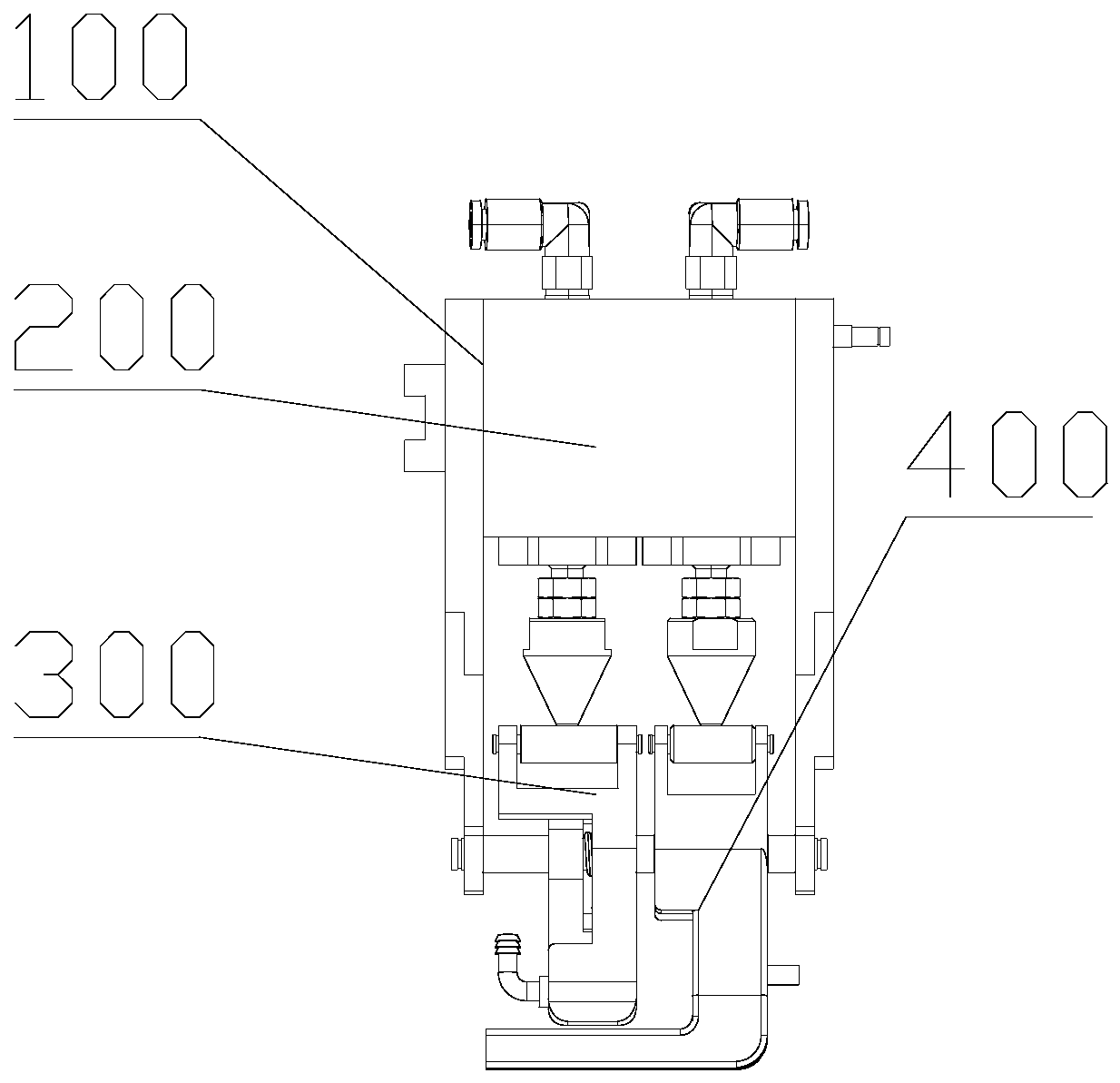

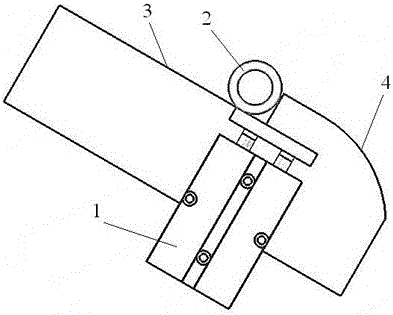

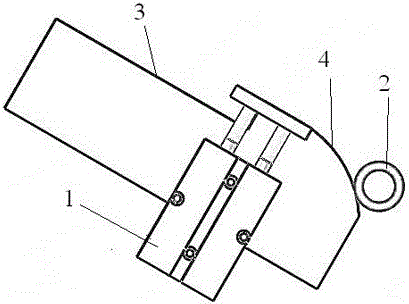

Power pouch battery exhausting and sealing clamp and exhaust sealing method

PendingCN111342103AImprove performance parametersImprove pass rateAssembling battery machinesFinal product manufactureBattery chargeElectrical battery

The invention discloses a power pouch battery exhausting and sealing clamp and an exhausting and sealing method, and the exhausting and sealing clamp comprises an installation support which is provided with an installation space; an air cylinder power mechanism which comprises an air cylinder assembly, an ejector head and an air cylinder fixing block; an exhaust clamp which comprises an exhaust clamp body, a piercing part and a sealed exhaust part, wherein the piercing part is arranged at the inner end of the battery clamping end of the exhaust clamp body, and the sealed exhaust part is arranged on the inner end surface of the battery clamping end; and a heating sealing clamp which comprises a sealing clamp body and a heating part. The method comprises the following steps: adjusting the position of the exhausting and sealing clamp, so that the battery air bag is arranged at the openings of the exhausting clamp and the sealing clamp; exhausting air; performing sealing; and enabling thetwo cylinder power assemblies to return to the top head, so the exhaust clamp body and the sealing clamp body are automatically opened, and exhausting and sealing are completed. The invention has thebeneficial effects that gas exhausted in the battery charging reaction process in the pouch battery formation process is exhausted, and the battery pack is sealed.

Owner:ZHEJIANG HANGKE TECH

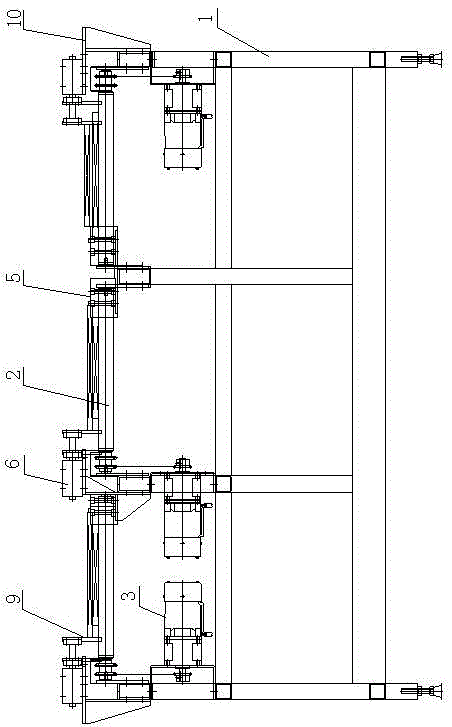

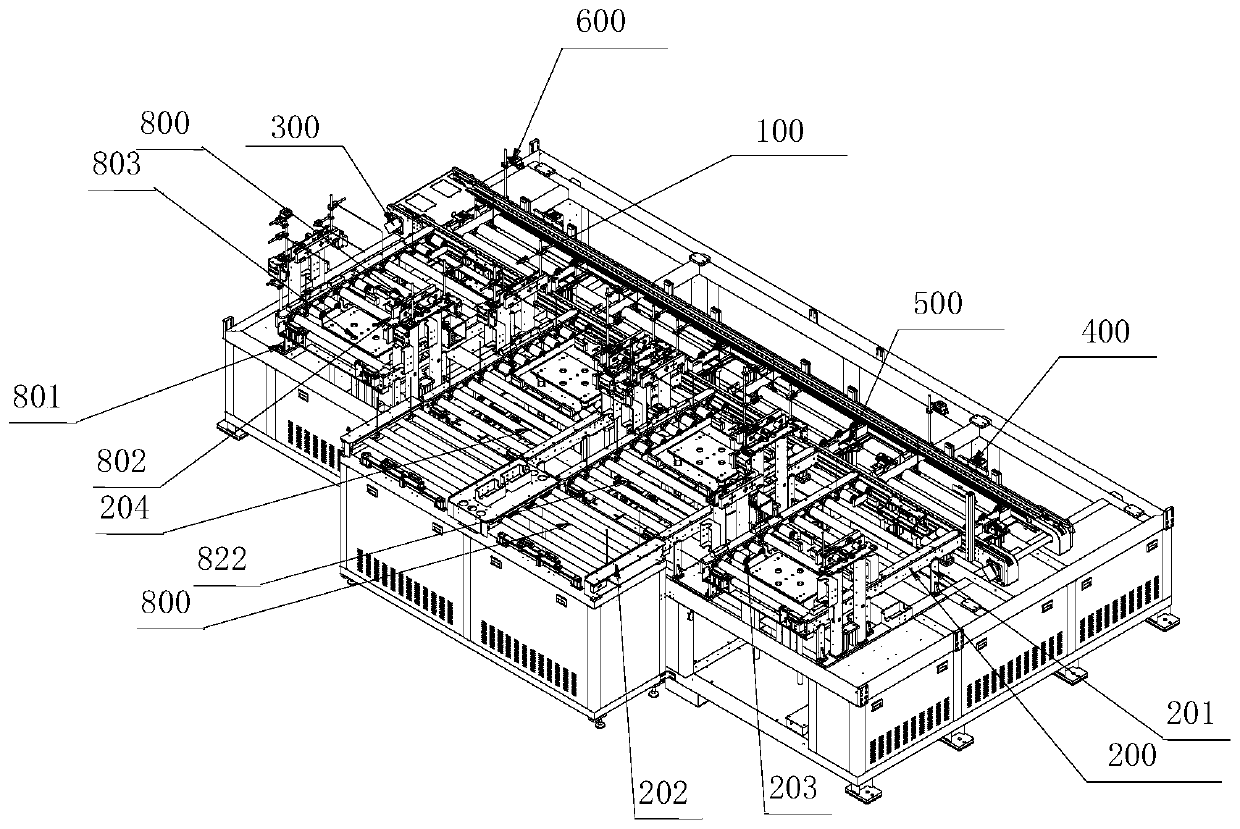

Conveying line tray slow storage device

PendingCN111302010AImprove efficiencyReduce dependencyConveyorsConveyor partsControl engineeringProcess engineering

The invention provides a conveying line tray slow storage device. The conveying line tray slow storage device comprises a rack, a conveying unit, a cylinder position adjusting unit, a code scanning unit and a control unit, wherein the rack is provided with a mounting platform, and a supporting mechanism is mounted on the mounting platform and used for supporting other components of a conveying line mechanism; the conveying unit comprises a speed chain conveying mechanism and multiple roller conveying mechanisms and is used for conveying trays; the cylinder position adjusting unit comprises atleast one cylinder locating mechanism and at least one cylinder blocking mechanism, the at least one cylinder locating mechanism is arranged in the position, beside the speed chain conveying mechanism, of the mounting platform in the axial direction and used for driving the trays on the speed chain conveying mechanism to realize locating of the trays; the at least one cylinder blocking mechanism is arranged on the speed chain conveying mechanism in the axial direction and used for blocking the trays on the speed chain conveying mechanism; the code scanning unit is used for conducting code scanning on the trays, identifying and storing tray information and scanning codes of the trays to determine the tray information; and the control unit is used for controlling operation of the whole conveying line mechanism. The conveying line tray slow storage device has the beneficial effects of being capable of improving the production efficiency and beneficial to production automation.

Owner:ZHEJIANG HANGKE TECH

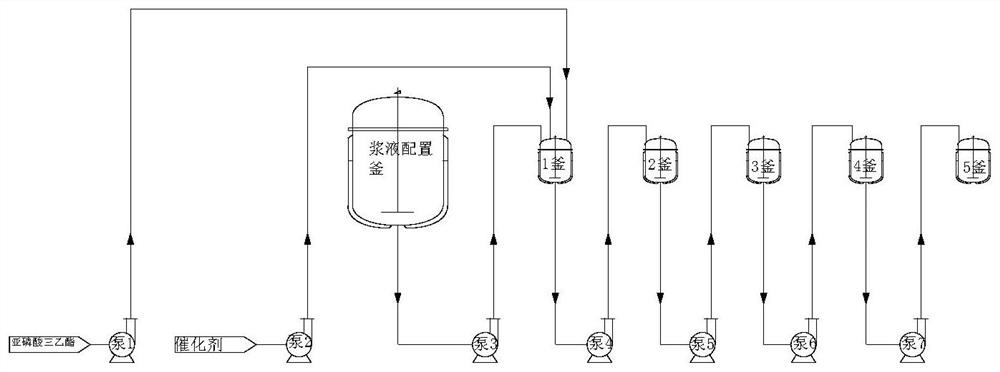

Method for continuously synthesizing cefixime side chain acid active ester

The invention discloses a method for continuously synthesizing cefixime side chain acid active ester. The method comprises the following steps: adding slurry of cefixime side chain acid and dithiobenzothiazole, a catalyst and triethyl phosphite into a first-stage reaction kettle of serially connected reaction kettles in proportion, starting stirring, and transferring materials among the serially connected reaction kettles through a metering pump; and controlling the reaction kettles connected in series to keep a certain temperature, enabling the reaction liquid to flow out of the last-stage reaction kettle and then enter a cooling kettle, filtrating the obtained reaction liquid after the reaction is completed to obtain a crude product, and post-processing the crude product to obtain the cefixime side chain acid active ester product. The method has the advantages that cefixime side chain acid active ester synthesis realizes continuous reaction, variable control in the reaction process is more stable, the problems of multiple ectopic control points, poor product quality uniformity and low production efficiency caused by intermittent reaction are solved, the product quality consistency is remarkably improved, and the method is suitable for industrial large-scale production.

Owner:山东普洛得邦医药有限公司 +1

Replaceable battery feeding and discharging waterwheel assembly

The invention relates to a replaceable battery feeding and discharging waterwheel assembly, which comprises a waterwheel body assembly comprising a supporting mechanism and a speed chain conveying mechanism and used for driving waterwheel clamp assemblies on the speed chain conveying mechanism to move; multiple sets of waterwheel clamp assemblies fixedly installed between the two speed chains side by side in the longitudinal direction, wherein each set of waterwheel clamp assembly comprises a transverse aluminum profile and at least one pair of waterwheel clamps, and the waterwheel clamp assemblies are used for clamping and caching the batteries to enable the batteries to be arranged on the waterwheel in order; a waterwheel clamp adjusting and pitch-changing assembly, which comprises at least one pair of waterwheel adjusting assemblies and at least one pair of waterwheel clamp adjusting assemblies and is used for driving waterwheel clamps to move oppositely or reversely in the transverse direction; and a waterwheel adjusting rod supporting assembly, which comprises a transverse straight guide rail and a pair of transverse sliding parts and is used for supporting and adjusting the transverse distance between the two waterwheel adjusting assemblies. The product has the beneficial effects that the battery abrasion is reduced, and the production efficiency is improved; a waterwheel clamp is automatically or manually remodeled, production automation is facilitated, and cost is saved.

Owner:ZHEJIANG HANGKE TECH

A method of correcting the drape and rigidity of copper starter plate

The invention relates to a method for correcting the pendency and rigidity of a copper starting sheet, and belongs to the technical field of non-ferrous metallurgy. Firstly, the copper starting sheet on a conveyer is pushed into a pattern pressing device through an air cylinder. Secondly, the patterned copper starting sheet is conveyed into a rod penetrating and lug nailing device. Thirdly, the copper starting sheet is conveyed into a patting shaping device which simulates the motions of manual patting shaping to carry out transverse patting shaping on the bottom of the copper starting sheet and vertical patting shaping on the upper half portion of the copper starting sheet. Finally, the copper starting sheet is conveyed to a storage frame. The method can improve the grooving rate of the copper starting sheet, reduce the phenomenon of point discharge, and simulate the electrolysis state of the copper starting sheet during patting shaping. The copper starting sheet is always in a suspension state and directly conveyed onto the storage frame after being shaped, deformation caused during transportation can be reduced, and it is guaranteed that the pendency is not changed before grooving. In addition, the method for correcting the pendency and rigidity of the copper starting sheet is simple in machining process, good in effect, low in cost and capable of realizing production automation extremely easily.

Owner:KUNMING UNIV OF SCI & TECH

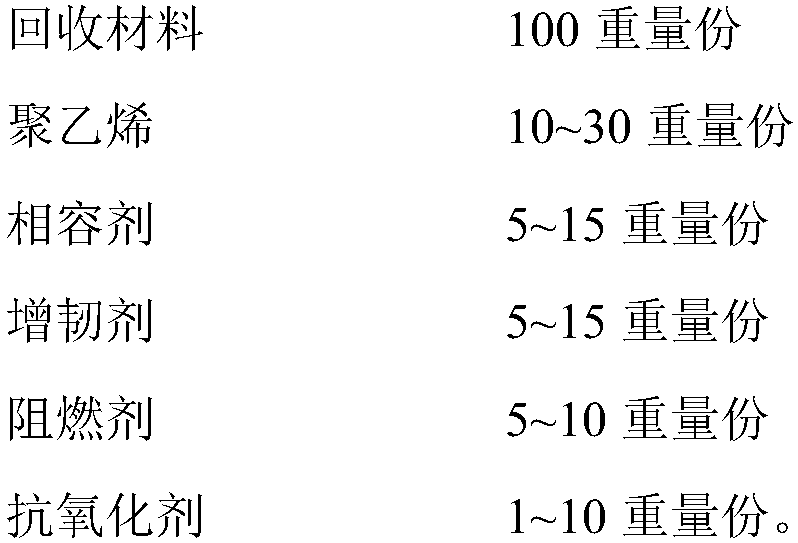

Air conditioner fan coil pipe water receiving tray production method

The invention relates to an air conditioner fan coil pipe water receiving tray production method, which comprises: 1) adding each raw material component of an air conditioner fan coil pipe water receiving tray into a mixer, and carrying out preliminary mixing to obtain a premix; 2) adding the premix into a screw extruder through a feeder, and carrying out extrusion granulation to obtain modified plastic granules; and 3) drying the obtained modified plastic granules, pouring the dried granules into an injection molding machine, and carrying out injection molding. The method of the present invention can effectively shorten the molding cycle, save materials and reduce waste products, and is beneficial to production automation, wherein the yield of the processed air conditioner fan coil pipe water receiving tray is up to more than 95%.

Owner:上海中宝环保科技集团股份有限公司

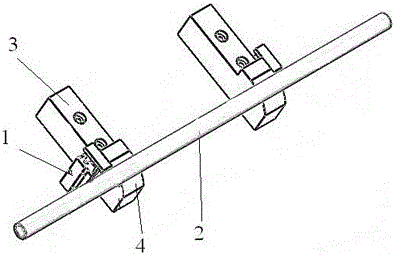

A round tube rotation assisting device

Owner:昆山三众汽车部件制造有限公司

A device for sorting and collecting smart cards

ActiveCN113184272BGuaranteed uptimeFacilitate production automationPaper article packagingControl engineeringSmart card

The present invention relates to the technical field of smart card attachments, in particular to a sorting and collecting device for smart cards, which has a simple structure and can automatically push the cards to the downstream conveyor belt after the cards are stacked, reducing the operator's operating steps and facilitating automation Production, improve work efficiency; including: abutment, as the base of the whole device, on which is provided with a driving mechanism, a lifting mechanism, a discharge mechanism, an upstream conveyor belt and a downstream conveyor belt, the abutment is T-shaped as a whole, and a For the L-shaped frame body, a limit plate is installed on one side of the frame body, and a guide plate is installed on the opposite side of the frame body and the limit plate; the driving mechanism is used to drive the lifting mechanism and the discharge mechanism; the lifting mechanism is equipped with a The baffle, the lifting mechanism is used to lift the baffle so as not to hinder the movement of the card; the output mechanism is equipped with a push plate at the output end, and the output mechanism is used to push the card to the downstream conveyor belt.

Owner:SHENZHEN YUANMINGJIE TECH

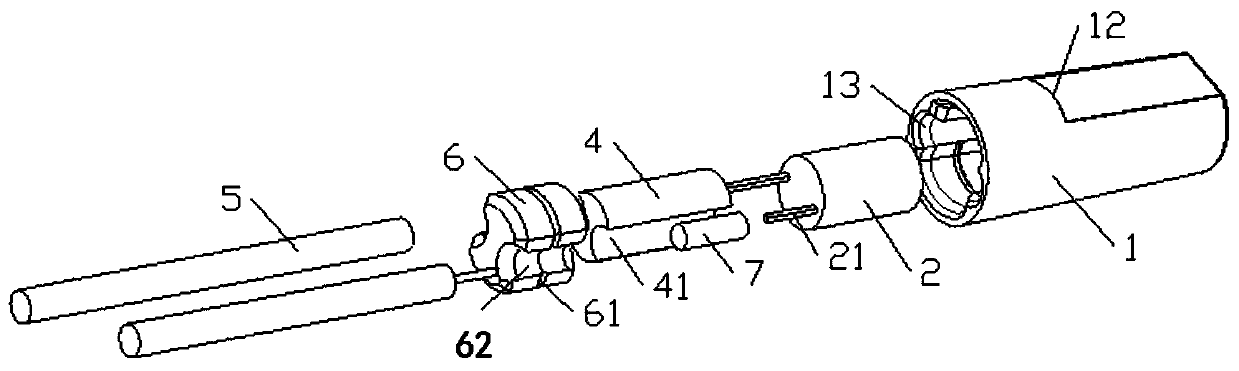

Decorative lamp and manufacturing method thereof

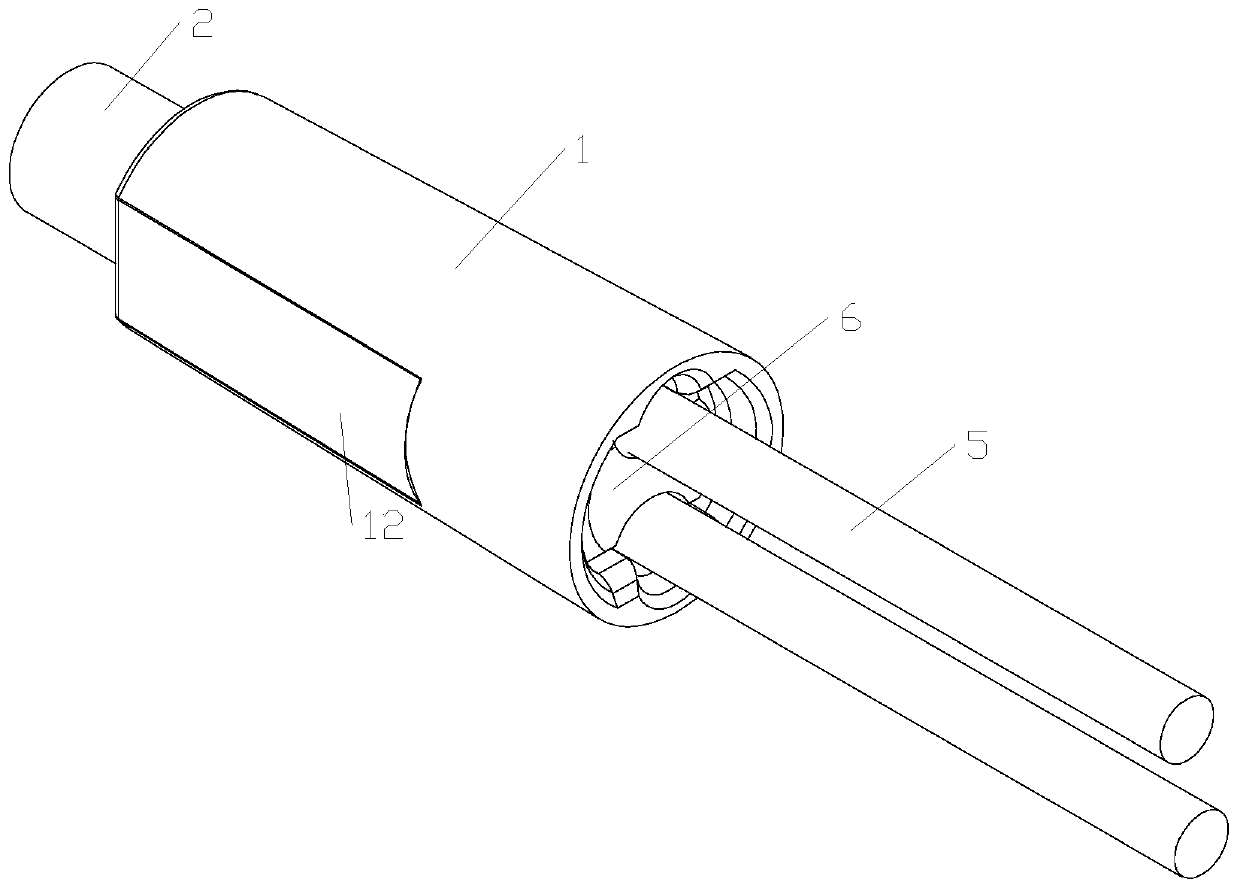

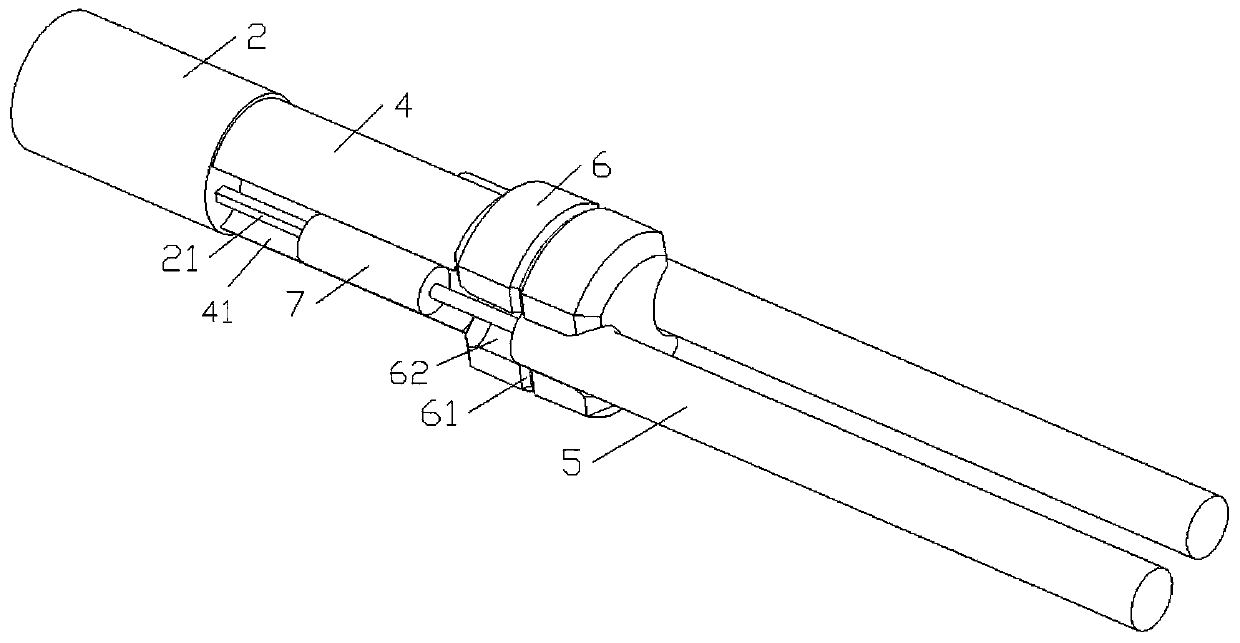

InactiveCN110617425AEasy to installEasy to disassembleLighting support devicesElectric circuit arrangementsEngineeringAutomation

The invention relates to a decorative lamp and a manufacturing method thereof; a mounting shell is included; a through hole penetrating through the front and rear end surfaces is formed in the mounting shell; a lamp wick is arranged on the front end face of the through hole in a penetrating mode, the rear end face of the lamp wick is arranged in the through hole, an isolation block and a tail plugare sequentially arranged on the rear end face of the lamp wick in the penetrating direction of the lamp wick, a clamping ring is arranged on the surface of the tail plug in a protruding mode, and aclamping ring groove matched with the clamping ring is concavely formed in the through hole. The shape of the tail plug is matched with the shape of the through hole, the tail plug is concavely provided with a first wire slot for a guide to penetrate through; a second wire slot matched with the first wire slot is concavely formed in the mounting shell, and a wire connected with the lamp wick polefoot can be discharged from a circular channel formed by the first wire slot and the second wire slot; a step structure is arranged on the outer side wall of the mounting shell; by improving the structure and process, the lamp wick is installed in the mode that the head penetrates through the mounting shell when the lamp wick is installed, and automation of production is facilitated.

Owner:DONGGUAN KAILANG IND

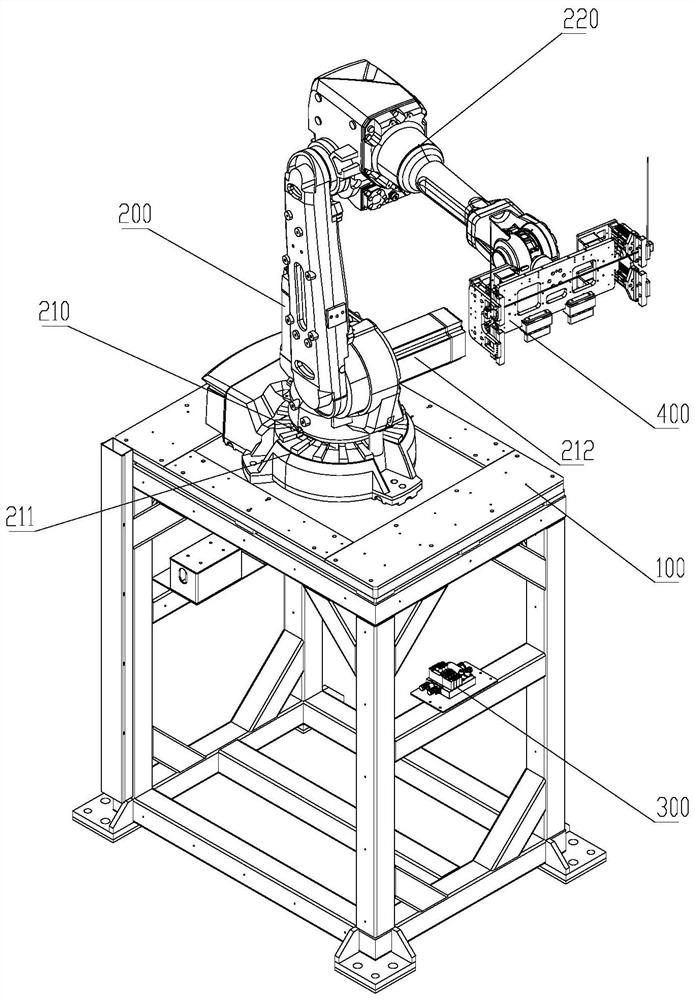

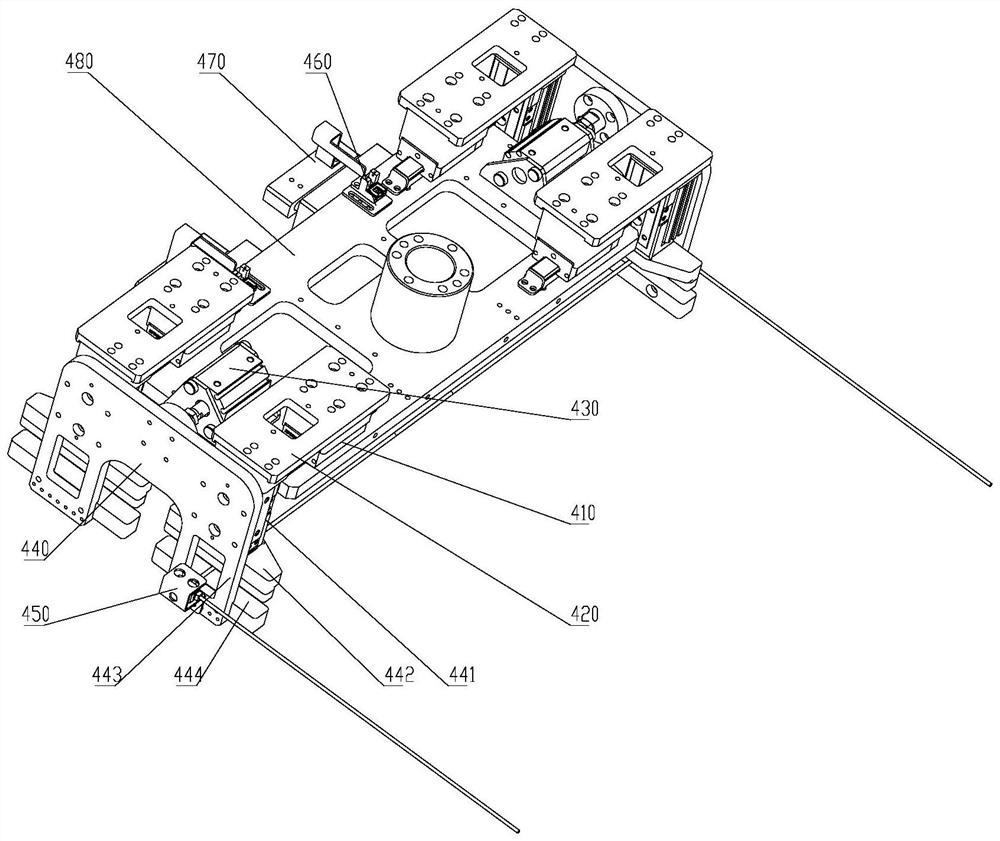

Six-axis carrying mechanical arm for battery burn-in board

PendingCN113734787AIncrease productivityOptimize battery qualityConveyor partsPhysicsRobotic control

The invention relates to a six-axis carrying mechanical arm for a battery burn-in board. The six-axis carrying mechanical arm comprises a base, a six-axis mechanical arm body, a control mechanism and a clamping mechanism, wherein the six-axis mechanical arm body and the control mechanism are arranged on the base, and the signal output end of the control mechanism is electrically connected with the control end of the six-axis mechanical arm body and the control end of the clamping mechanism; the clamping mechanism is arranged at the movable tail end of the six-axis mechanical arm body and comprises a main connecting plate, two sets of transverse driving devices and a pair of clamping devices; the main connecting plate is fixedly arranged at the movable tail end of the six-axis mechanical arm body, and a linear track is arranged at each of the first end part and the second end part of the main connecting plate in a paving mode; the two sets of transverse driving devices are respectively arranged at the first end part and the second end part; the two sets of clamping devices are slidably arranged on the linear guide rails at the same end part through connecting plates and connected with the telescopic ends of the transverse driving devices; and the clamping parts of the two sets of clamping devices are positioned on the same side of the main connecting plate and are opposite to each other. The six-axis carrying mechanical arm has the beneficial effects of replacing manual carrying, improving the production efficiency, optimizing the battery quality and facilitating production automation.

Owner:ZHEJIANG HANGKE TECH

A device for accurately counting transparent capsules and its application method

InactiveCN102700784BRealize detectionImprove packaging efficiencyPackaging machinesEngineeringFluorescent lamp

The invention discloses a device for accurately counting transparent capsules and a using method thereof. The device for accurately counting the transparent capsules comprises a machine tool of a grain counting machine, a detection channel, a CCD (Charge Coupled Device) lens, a high frequency fluorescent lamp and a vibrating hopper. The detection channel, the CCD lens, the high frequency fluorescent lamp and the vibrating hopper are located above the machine tool of the grain counting machine. The detection channel is placed between the CCD lens and the frequency fluorescent lamp. Two grooves are formed in two side surfaces of the detection channel and are in a same plane with a center of the CCD lens. The detection channel is located right below the tail end of the vibrating hopper. The CCD lens consists of a DSP (Digital Signal Processor) detection system, a CCD drive plate, an array CCD and an optical lens. The counting device not only can count common medicine grains, but also can count the transparent capsules with a certain translucency, so as to improve the medicine packaging efficiency of a medicine production line and facilitate production automation of medicines.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

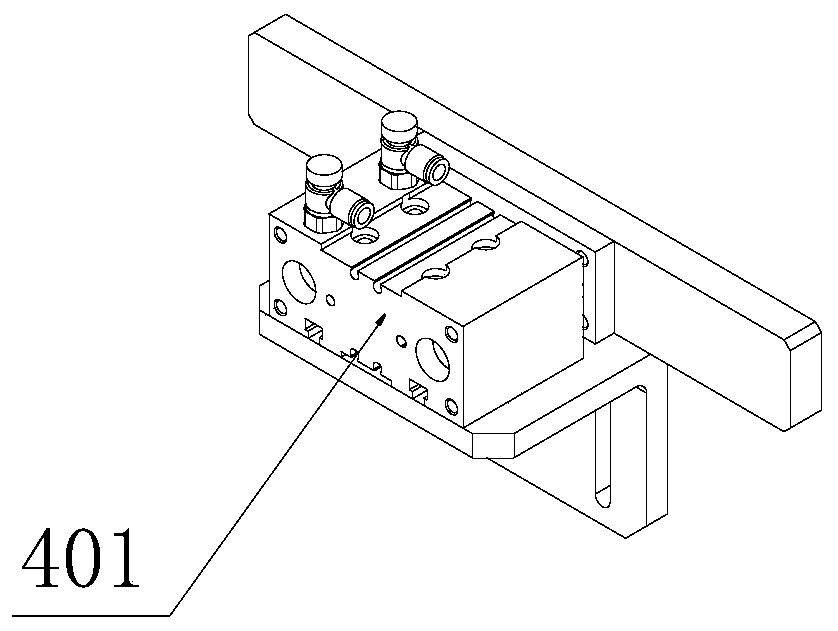

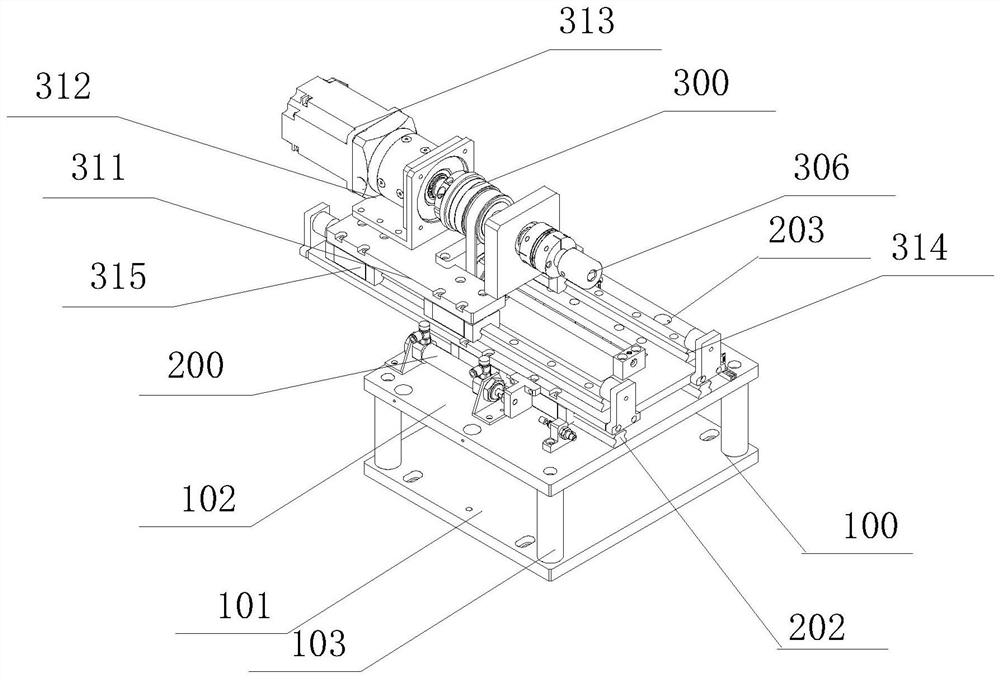

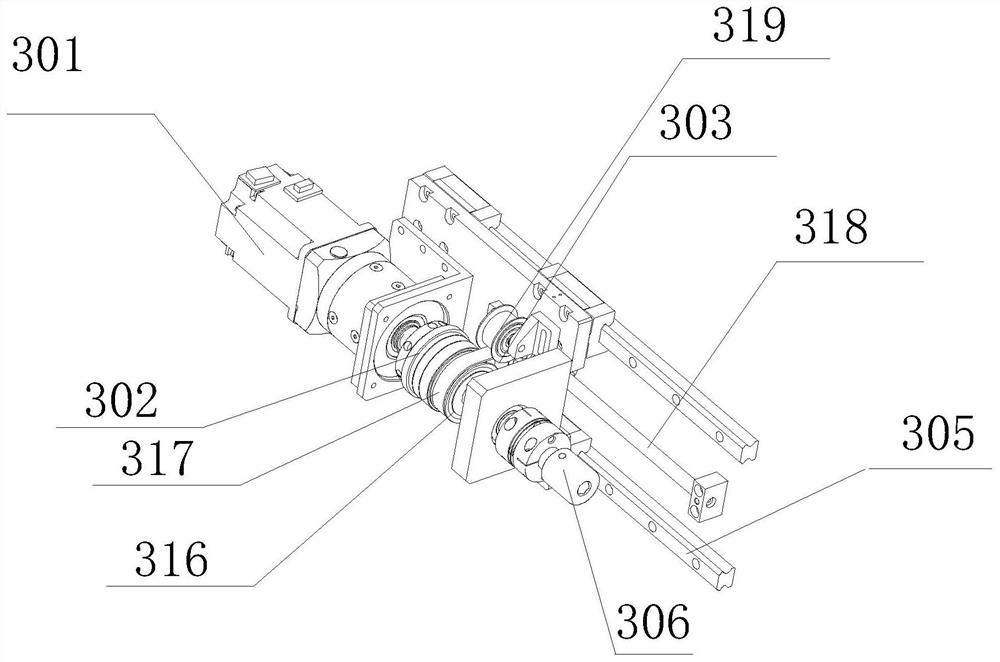

Locking device for battery restraining tray

PendingCN112224843AIncrease productivityFacilitate production automationConveyor partsControl engineeringElectric machinery

A locking device for a battery restraining tray comprises a base, a front-back driving device, and a synchronous movement mechanism, wherein the top of the base is provided with a mounting platform; the front-back driving mechanism is arranged on the base, and comprises a driving device, a fixed guide rail sliding block assembly, and a sliding block fixing plate; a pushing end of the driving device is connected with the fixed guide rail sliding block assembly; a sliding part of the fixed guide rail sliding block assembly is fixedly provided with the sliding block fixing plate; the sliding block fixing plate is connected with the pushing end of the driving device by a connecting piece; the synchronous movement mechanism is arranged on the front-back driving mechanism, and comprises a motordriving device, a torque limiting device, a lead screw transmission device, a synchronous pulley transmission device, and a movable guide rail sliding block device; the motor driving device is mountedon the sliding block fixing plate in a sliding manner by the movable guide rail sliding block device; a sleeve head is assembled at an end of an output shaft of the torque limiting device; and the screw rod transmission device is in belt connection with the output shaft of the torque limiting device by the synchronous pulley transmission device. The locking device has the beneficial effects of improving production efficiency, pipelining a product, and facilitating production automation.

Owner:ZHEJIANG HANGKE TECH

Magnetic material for motor slot wedge

InactiveCN102593967ALow toxicityWide tolerance in useMagnetic circuit characterised by magnetic materialsEpoxyFiber

Owner:无锡市万邦机械制造厂

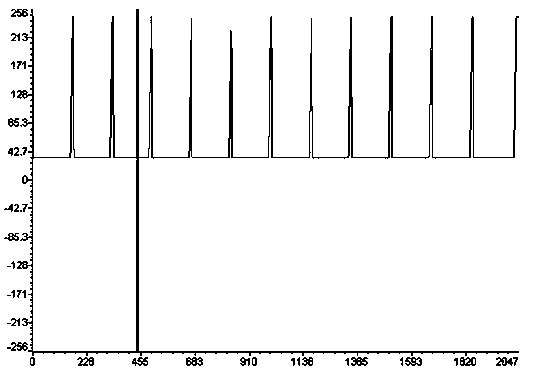

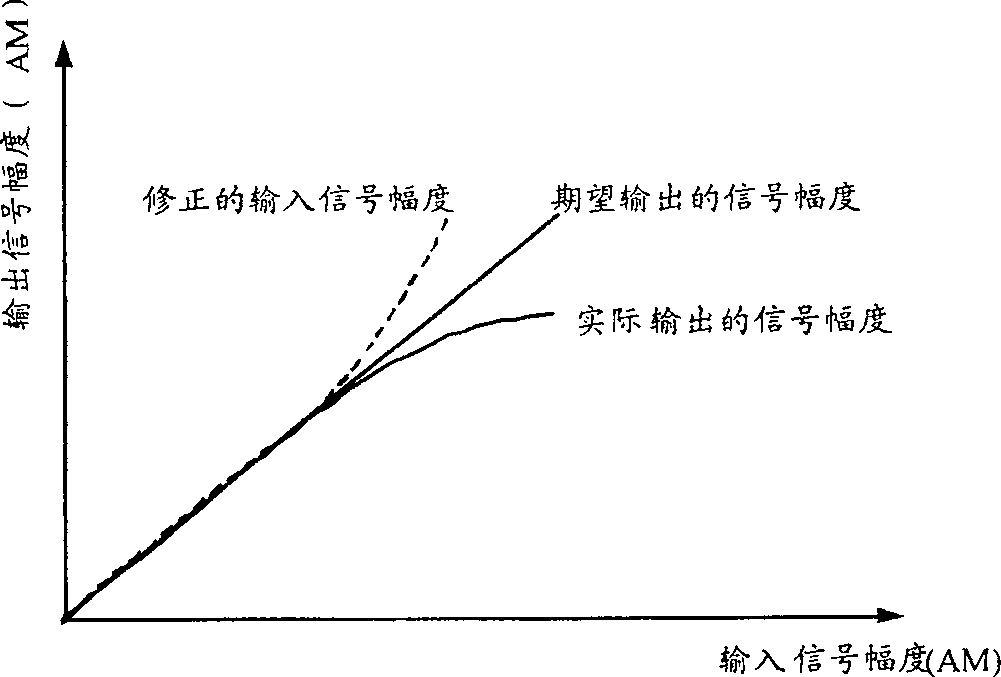

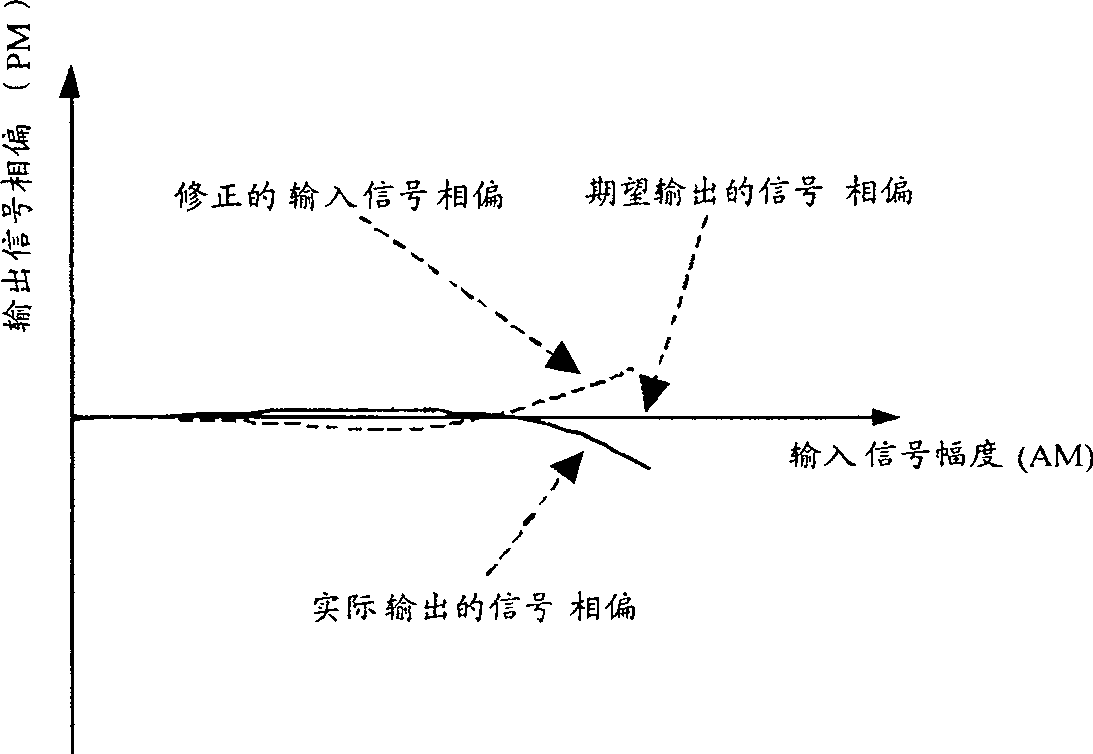

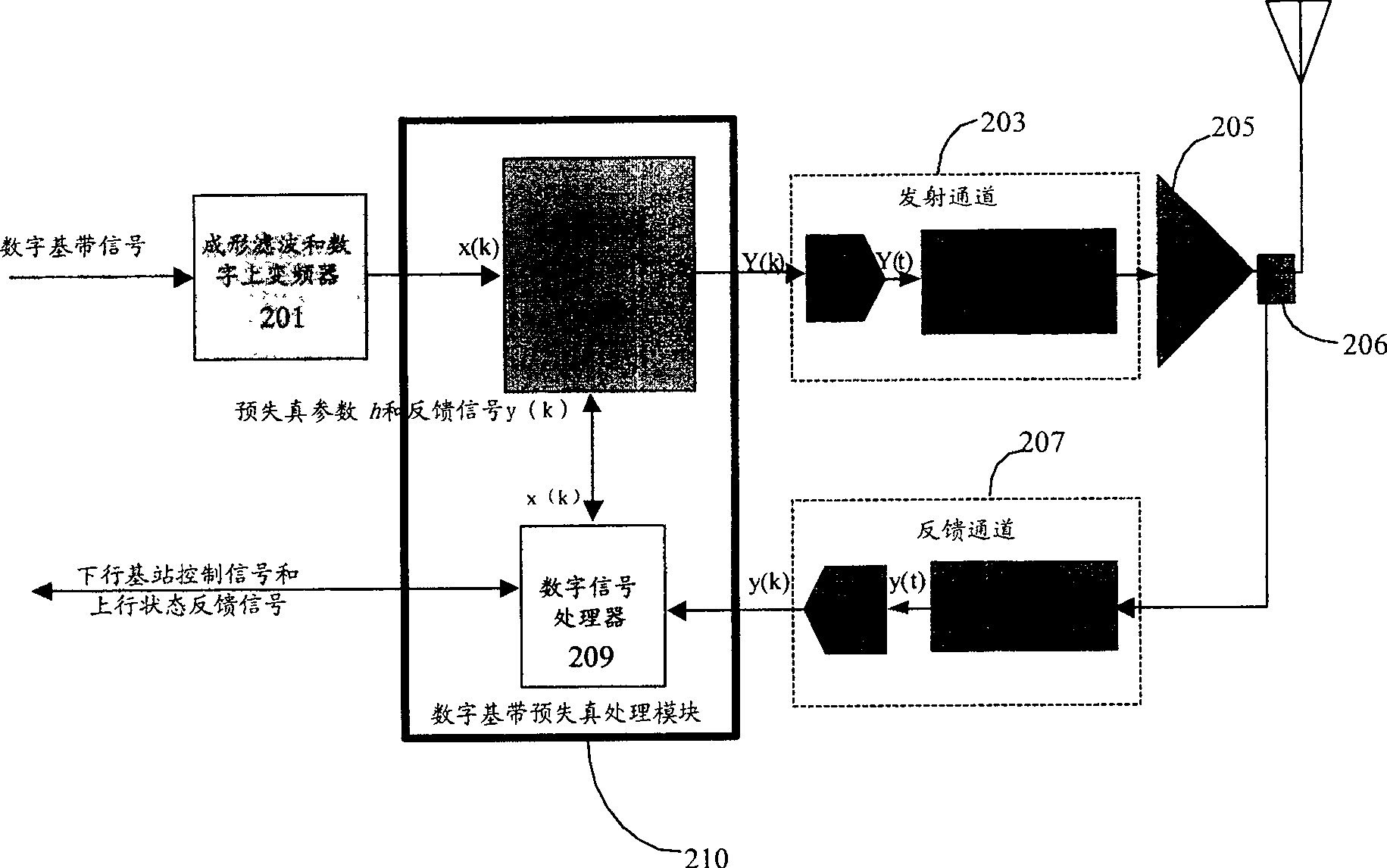

Power amplifying system and method for generating pre-distortion signals

InactiveCN100511979CImprove linearization performanceReduce power consumptionAmplifier modifications to reduce non-linear distortionPower amplifiersComputer scienceVolterra series

The invention discloses a power amplifier system and a method for generating a pre-distortion signal. The power amplifier system calculates the transmission digital signal and the feedback digital signal in a digital signal processor (DSP), extracts pre-distortion parameters, and provides the parameters to A pre-distortion chip based on the Volterra series model or its derivative model. The pre-distortion chip uses the Volterra series model and its derivative model to perform pre-distortion processing on the transmitted digital signal to obtain a pre-distortion signal, and then transmit the pre-distortion signal through the The channel is sent to the power amplifier for amplification, and the method can greatly improve the linearity and efficiency of the power amplifier, facilitate the automation of production, and reduce the production cost and maintenance cost.

Owner:HUAWEI TECH CO LTD

Quick charger assembling method

PendingCN112688376AImprove cooling efficiencyReduce packaging process stepsBatteries circuit arrangementsCasings/cabinets/drawers detailsUltrasonic weldingSilica gel

The invention provides a quick charger assembling method. The method comprises the following steps that (1) a PCB is arranged in a shell main body, wherein the PCB comprises a circuit board main body part and a circuit board connecting part; an interlayer is arranged in the shell main body to divide the shell main body into an upper cavity and a lower cavity, and the interlayer is provided with a through hole only allowing the circuit board connecting part to penetrate through; the circuit board main body part is arranged in the lower cavity, the circuit board connecting part penetrates through the through hole of the interlayer to enter the upper cavity, and the circuit board connecting part is connected with an alternating current plug arranged in the upper cavity; and ultrasonic welding is carried out on the upper cover plate and the shell main body; (2) the shell main body is inverted, and silica gel is poured into the lower cavity of the shell main body until the silica gel is cured; and (3) ultrasonic welding is carried out on the lower cover plate and the shell main body. According to the quick charger assembling method, the packaging process steps are greatly reduced, the production process is greatly simplified, and the assembling efficiency is improved.

Owner:GUANGZHOU ZHONGYIGUANG ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com