Conveying line tray slow storage device

A conveyor line and pallet technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of unable to find the correct use of the produced materials, untimely supply of pallets, confirmation of pallet information, etc., so as to facilitate production The effects of automation, reducing human dependence, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

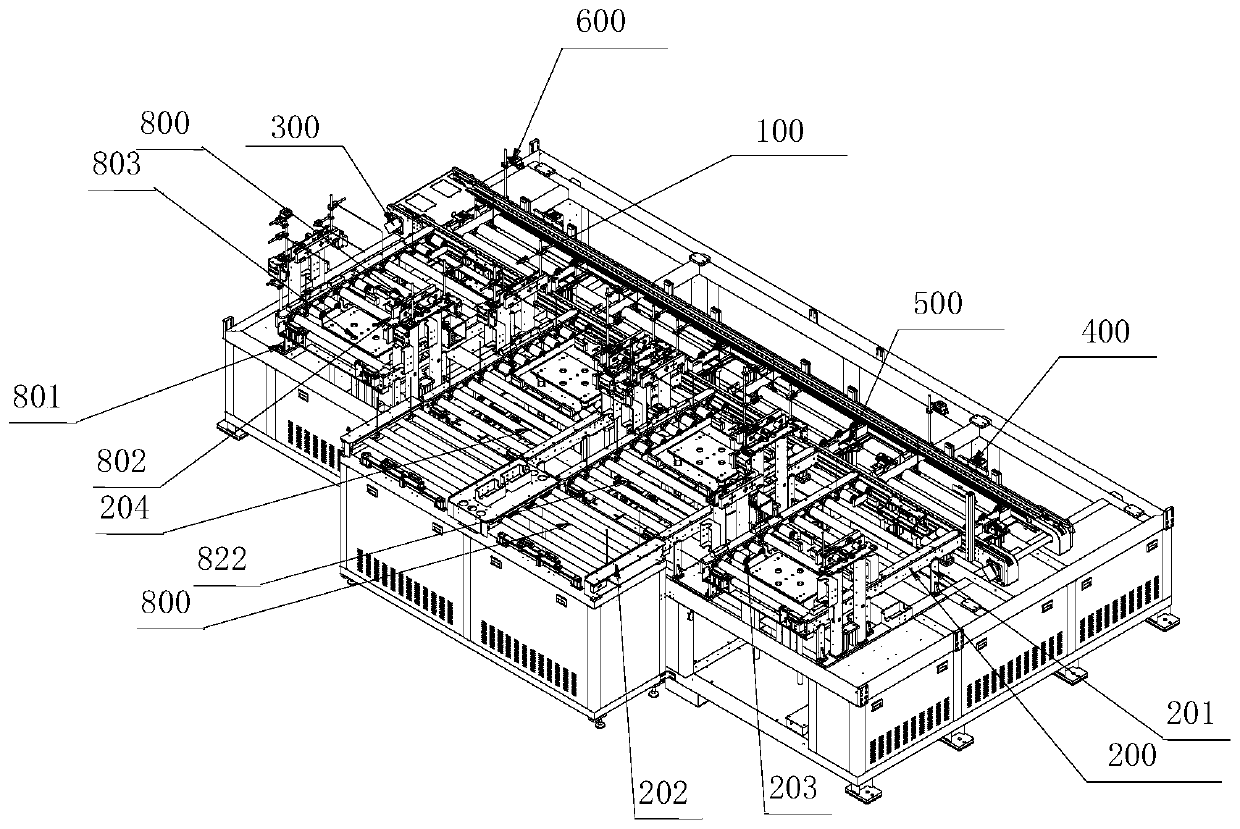

[0035] Embodiment 1 A conveyor line buffer tray device according to the present invention includes:

[0036] The frame 700 has an installation platform, and the support mechanism 200 is installed on the installation platform for supporting other parts of the conveyor line mechanism;

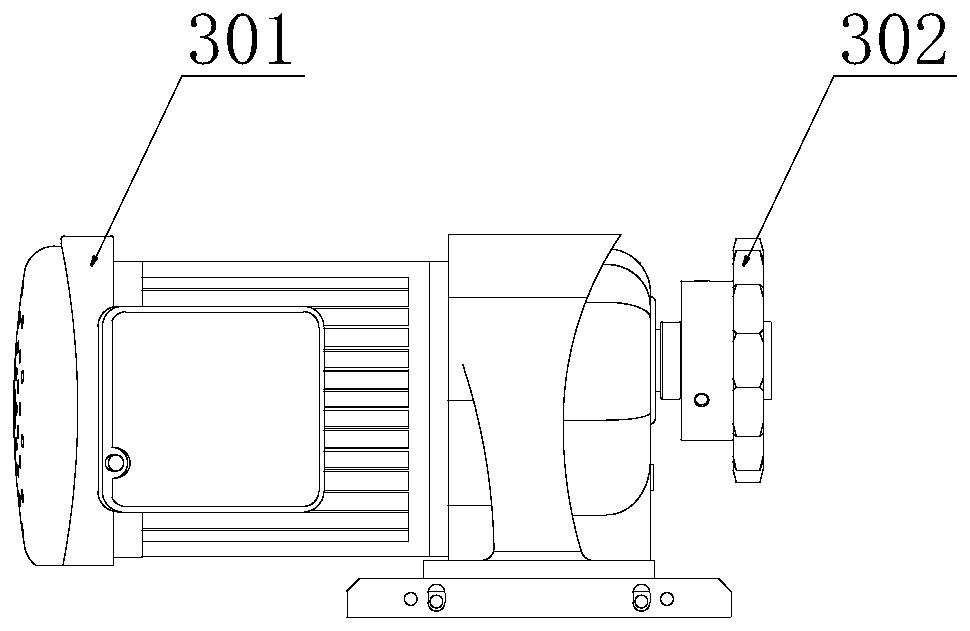

[0037] The conveying unit includes a double-speed chain conveying mechanism 100 and multiple sets of roller conveying mechanisms 800. The roller conveying mechanisms 800 are paved side by side on the installation platform through the support mechanism 200, and the downstream output end of the roller conveying mechanism 800 extends to the double-speed chain conveying mechanism 100, used to transport the pallet on the roller conveyor mechanism 800 to the double-speed chain conveyor mechanism 100; Do not exceed the rolling surface of the roller conveying mechanism for conveying pallets;

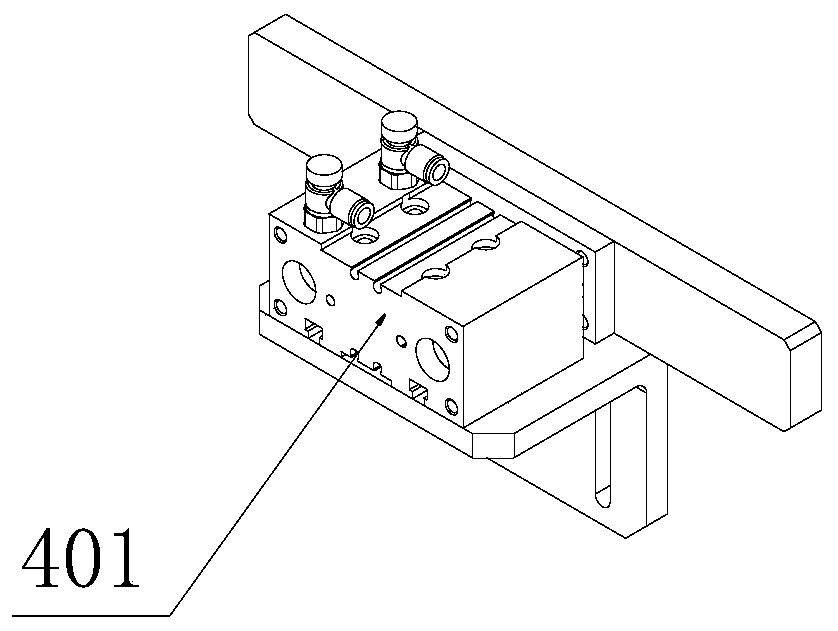

[0038] The cylinder position adjustment unit includes at least one set of cylinder positioning mechanism 400 an...

Embodiment 2

[0060] Embodiment 2 A conveying line buffer tray device described in this embodiment includes:

[0061] The frame 700 has an installation platform, and a support mechanism is installed on the installation platform for supporting other parts of the conveyor line mechanism;

[0062] The conveying unit includes a double-speed chain conveying mechanism 100 and multiple sets of roller conveying mechanisms 800. The roller conveying mechanisms are paved side by side on the installation platform through the supporting mechanism, and the downstream output end of the roller conveying mechanism extends to the double-speed chain conveying mechanism. To transport the pallet on the scanning roller conveying mechanism to the double-speed chain conveying mechanism; the double-speed chain conveying mechanism is laid on the end of the roller conveying mechanism, and the conveying surface of the double-speed chain conveying mechanism does not exceed the rolling of the roller conveying mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com