Locking device for battery restraining tray

A locking device and restraint technology, which is applied in the field of battery restraint tray locking devices, can solve the problems of battery overvoltage, uneven control, low voltage, etc., and achieve the effect of improving production efficiency and facilitating production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

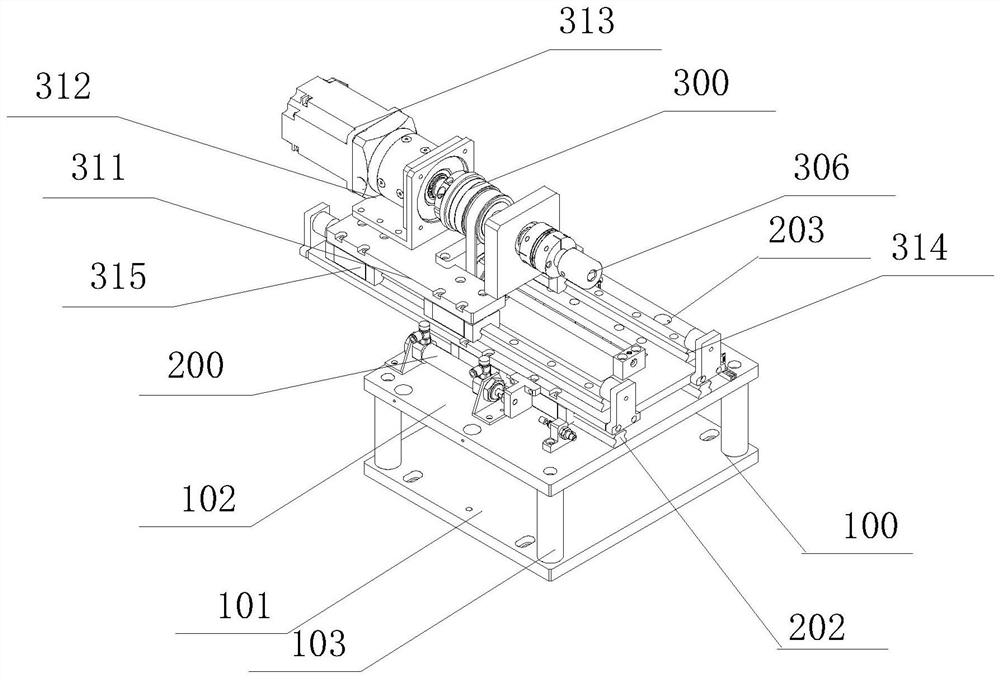

[0020] Embodiment 1 A battery restraint tray locking device according to the present invention includes:

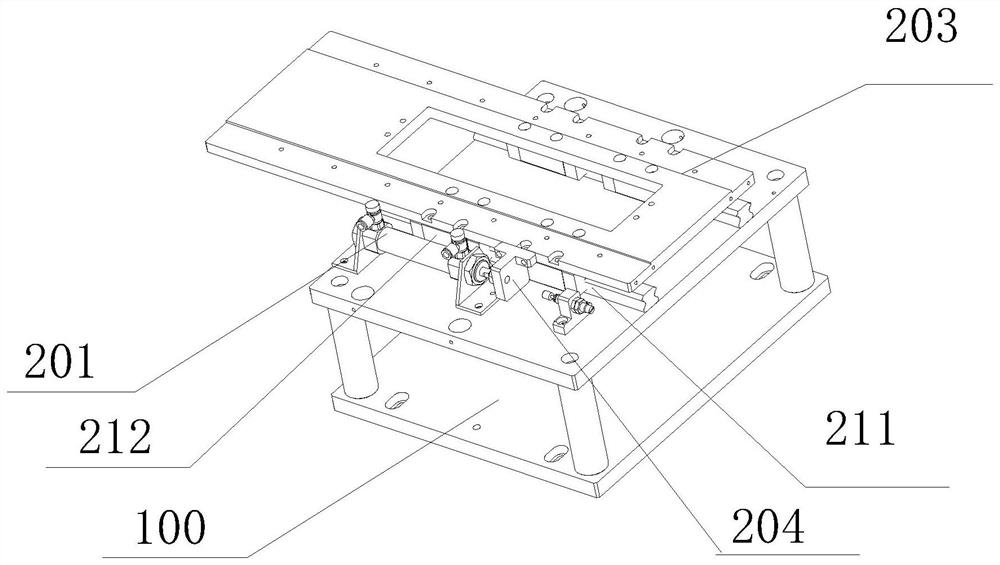

[0021] The base 100 is provided with a mounting platform on the top for supporting and installing the front and rear drive mechanisms;

[0022] The front and rear driving mechanism 200 is arranged on the base 100 and includes a driving device 201, a fixed rail slider assembly 202 and a slider fixing plate 203. The driving device 201 is fixed on the installation platform at the top of the base 100, and its pushing end It is connected with the fixed guide rail slider assembly to provide driving force; the fixed guide rail slider assembly 202 is laid on the installation platform of the base 100 along the driving direction of the driving device, and a slider fixing plate 203 is fixed on the sliding part for use Drive the slider fixing plate 203 to slide; the slider fixing plate 203 is arranged beside the driving device 201, and is connected with the pushing end of the driving...

Embodiment 2

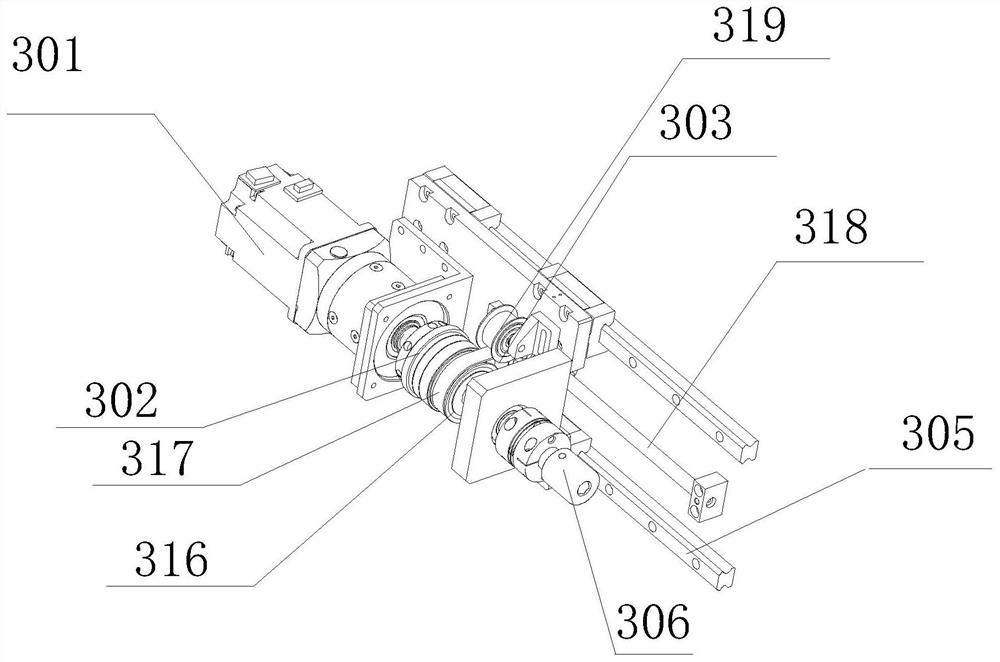

[0030] Embodiment 2 A battery restraint tray locking device according to the present invention includes a base, a front and rear drive mechanism and a synchronous movement mechanism. The front and rear driving mechanism includes a driving device, a fixed guide rail slider assembly and a slider fixing plate, which are arranged on the base. The synchronous motion mechanism is arranged on the slider fixing plate of the front and rear drive mechanism, and the synchronous motion mechanism is composed of a motor drive device, a torque limiting device, a screw drive device, a synchronous pulley drive device and a moving guide rail slider device composition.

[0031] The battery restraint tray locking device provided by the present invention pushes the synchronous movement mechanism through the front and rear drive mechanism, so that the sleeve head on the synchronous movement mechanism docks with the head of the lead screw on the battery restraint tray. The motor drive unit of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com