Lithium ion battery and preparation method thereof

A lithium-ion battery and battery technology, applied in electrode manufacturing, secondary batteries, battery pack components, etc., can solve problems such as internal short circuits in batteries, and achieve the effects of easy production automation, production automation, and waste reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

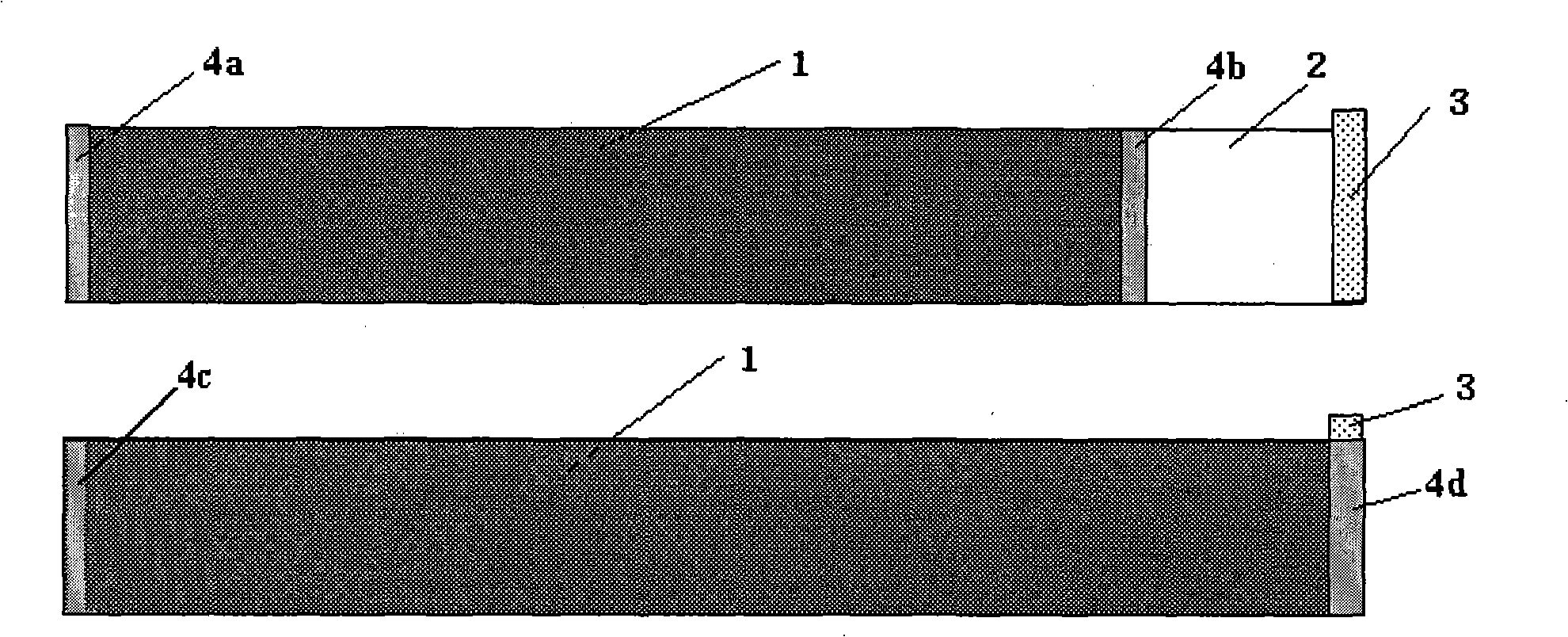

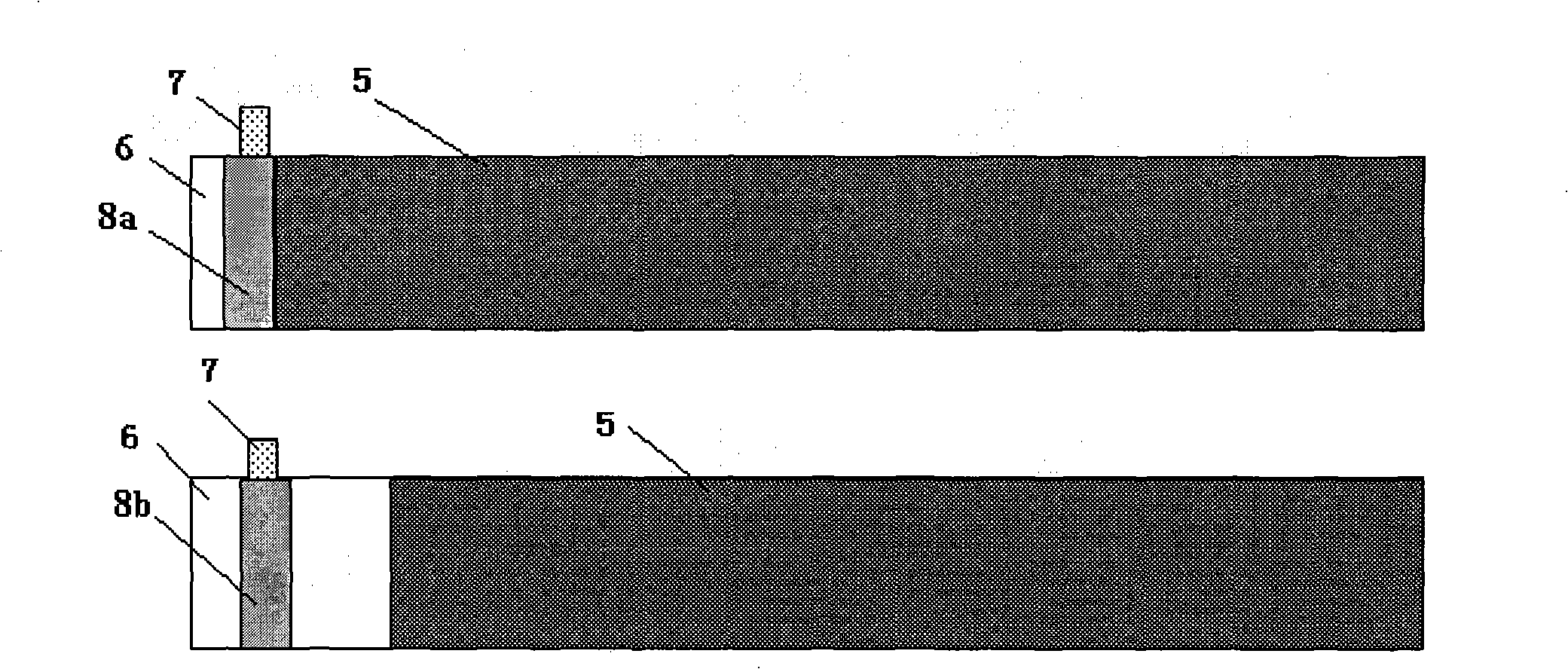

[0020]The preparation method of the lithium-ion battery provided by the present invention includes attaching the positive electrode material and the negative electrode material on the two surfaces of the positive electrode current collector and the negative electrode current collector respectively, and connecting the surface of one end of the positive electrode current collector and the surface of one end of the negative electrode current collector respectively. Positive pole tabs and negative pole tabs, positive pole pieces and negative pole pieces are prepared, and then the diaphragm is arranged between the positive pole pieces and the negative pole pieces to be wound to form an electrode group, the electrodes are assembled into the battery case and electrolyte solution is injected into it, wherein, The method also includes, after connecting the tabs and before preparing the electrode group, using an insulating coating to form an insulating coating layer on at least the follow...

Embodiment 1

[0030] This example is used to illustrate the lithium ion battery provided by the present invention and its preparation method.

[0031] 1. Preparation of positive electrode sheet

[0032] 100 g of LiCoO 2 The powder, acetylene black, PVDF and NMP were mixed in a weight ratio of 100:3:2:50 to prepare positive electrode slurry. The positive electrode slurry was evenly coated on a 16 micron aluminum foil, dried and rolled to obtain a positive electrode sheet with a thickness of 140 microns.

[0033] 2. Preparation of negative electrode sheet

[0034] Artificial graphite, SBR, CMC and water are mixed in a weight ratio of 100:2.5:1.5:120 to prepare negative electrode slurry, which is evenly coated on the surface of copper foil with a thickness of 10 microns, dried and rolled to obtain Negative electrode sheet with a thickness of 130 microns.

[0035] 3. Form a coating with insulating paint

[0036] Polyvinylidene fluoride (Kuruha Chemical, 7200), acetone and nano silicon oxid...

Embodiment 2

[0040] This example is used to illustrate the lithium ion battery provided by the present invention and its preparation method.

[0041] Prepare lithium-ion battery in the same manner as in Example 1, the difference is that step 3 is:

[0042] Polystyrene (weight average molecular weight is 100000), ethyl acetate, nano-alumina (Al 2 o 3 , the average diameter of the particles is 500 nanometers) mixed according to the weight ratio of 12:80:8, stirred evenly with a magnetic stirrer at 40°C, and prepared into an insulating coating. After the positive and negative pole pieces are tapped, apply the above insulating coating on the figure 1 4a-4d shown as well as figure 2 In the positions shown 8a and 8b, the coating is formed after the solvent evaporates. Wherein, the lug width of the positive and negative poles is 4 mm, the thickness of the coating 4a is 25 microns, and the width is 6 mm, the thickness of the coating 4b is 25 microns, and the width is 6 mm, and the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com