A device for accurately counting transparent capsules and its application method

A transparent and capsule technology, used in packaging, packaging machines, transportation and packaging, etc., can solve the problems of reducing drug packaging efficiency, unfavorable drug production automation, inability to count transparent capsules, etc. The effect of facilitating the automation of pharmaceutical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

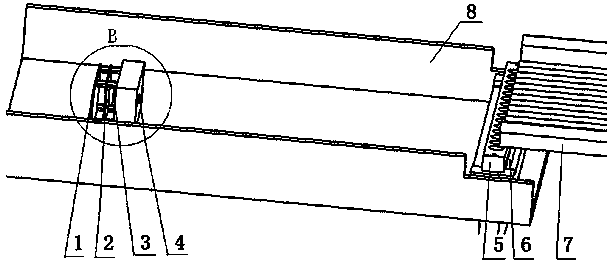

[0022] A device for accurately counting transparent capsules, consisting of a counting machine tool 8, a detection channel 5, a CCD lens, a high-frequency fluorescent lamp 6, and a vibrating hopper 7, the detection channel 5, a CCD lens, a high-frequency fluorescent lamp 6, and a vibrating hopper 7 Located above the machine tool 8 of the counting machine, its structural diagram is as follows figure 1 shown;

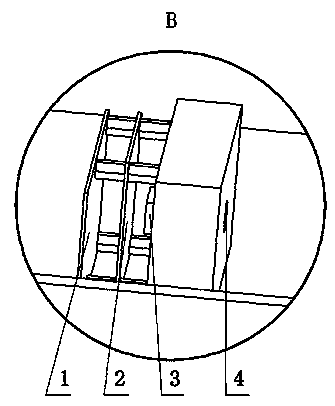

[0023] The structural representation of the CCD lens is figure 1 The enlarged picture of B in figure 2 As shown, the CCD lens is composed of a DSP detection system 1, a CCD driver board 2, a linear array CCD 3, and an optical lens 4. The DSP detection system 1 and the linear array CCD3 are connected to the CCD driver board 2 through a slot, and the CCD The driving board 2 is located between the two, and the optical lens 4 is located directly in front of the line array CCD3.

[0024] The detection channel 5 is placed between the CCD lens and the high-frequency fluoresc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com