Decorative lamp and manufacturing method thereof

A technology for decorative lamps and wicks, which is applied in decorative art, special patterns, lighting devices, etc., can solve the problems of unfavorable automation degree, meager profit of decorative lamps, and automatic transformation of production processes, so as to achieve low cost of automation transformation, facilitate automation transformation, and facilitate The effect of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with accompanying drawing:

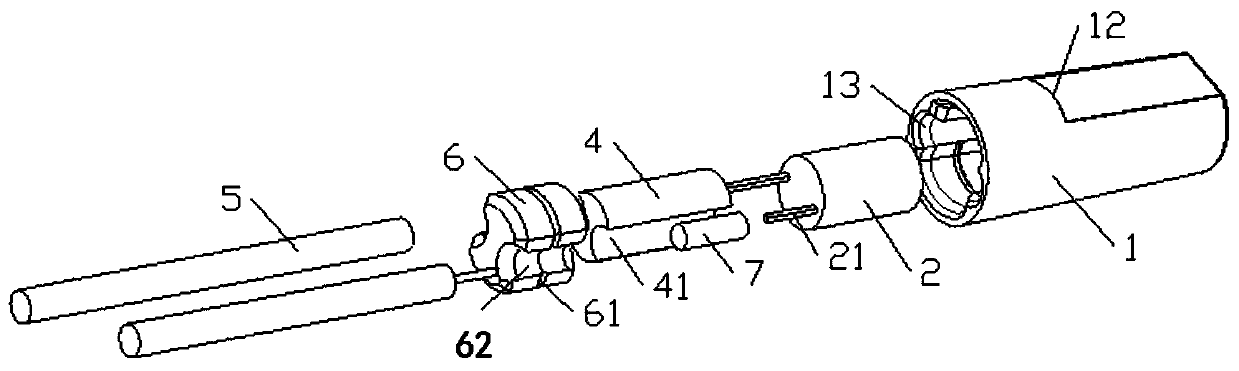

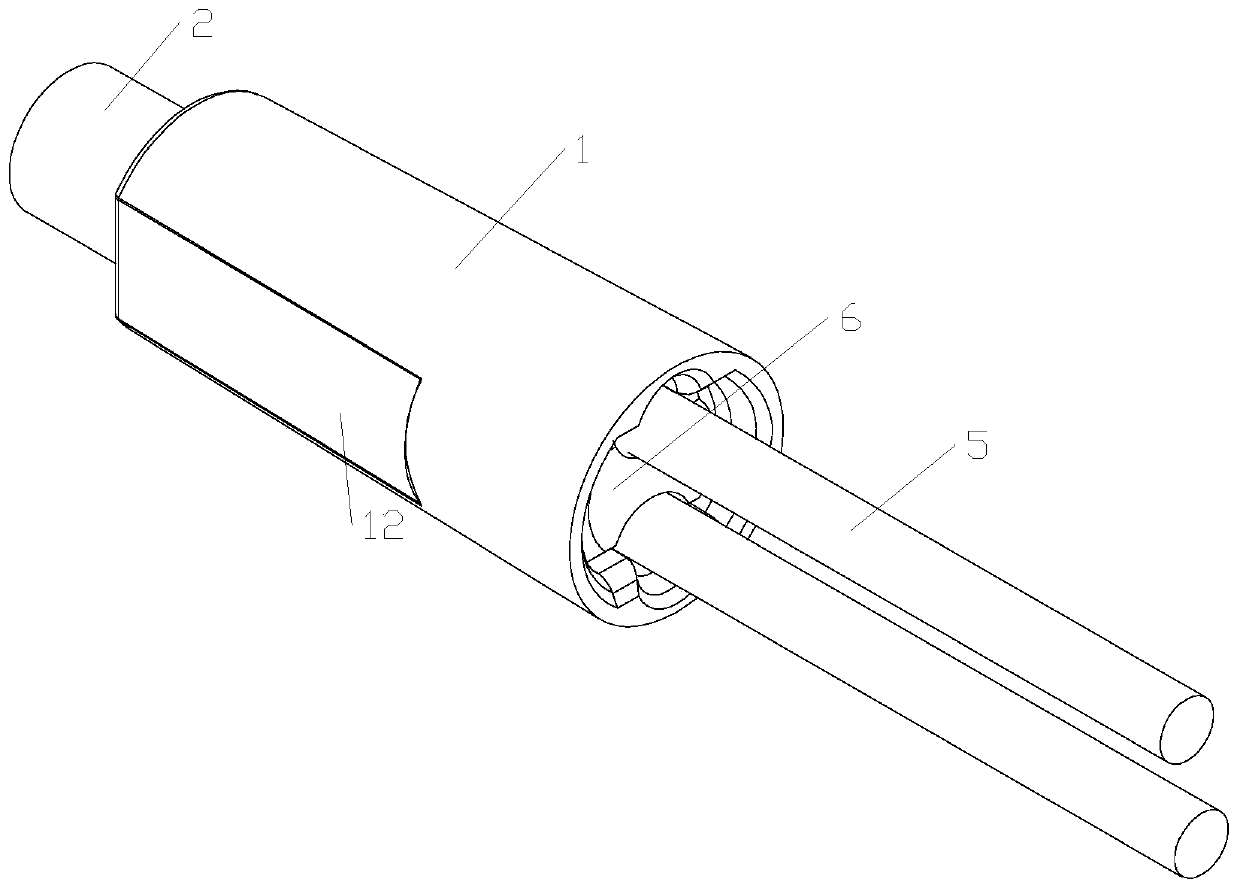

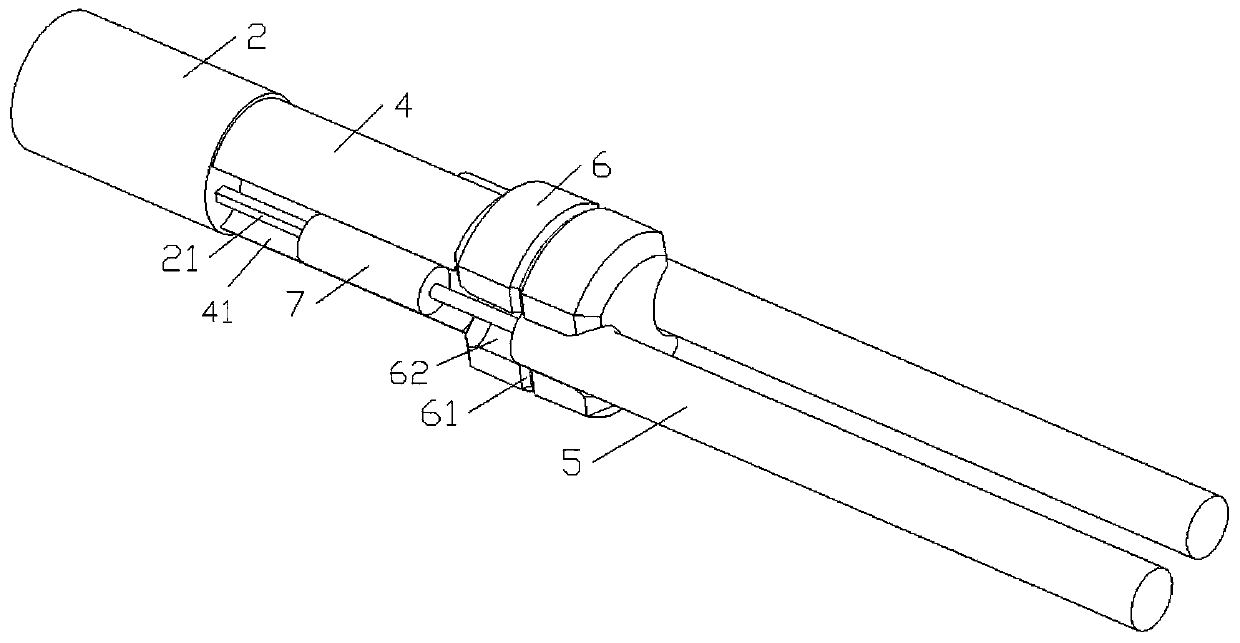

[0034] Such as figure 1 , figure 2 As shown, a decorative lamp includes a mounting shell 1, a wick 2, an insulating block 4, a tail plug 6 and a wire 5 for connecting to the pole pins of the wick 2, and the wick 2 has two pole pins.

[0035] Such as Figure 4 , Figure 5 As shown, the mounting shell 1 is a vertebral platform whose radius gradually decreases from the rear end face to the front end face, the mounting shell 1 has a through hole 11 that runs through the front and rear end faces, and the outer wall of the mounting shell 1 is provided with a stepped structure 12. The step structure 12 includes a horizontal surface 122 for positioning and a clamping surface 121 for fixing, and the installation shell 1 is made of elastic material.

[0036] Such as figure 1 , figure 2 As shown, the front end of the through hole 11 is pierced with a wick 2, and the tail of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com