Quick charger assembling method

A fast charging charger and the technology of the fast charging charger are applied in the direction of current collectors, circuit devices, battery circuit devices, etc., and can solve the problems of many assembly methods, low assembly efficiency, low heat dissipation efficiency of fast charging chargers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

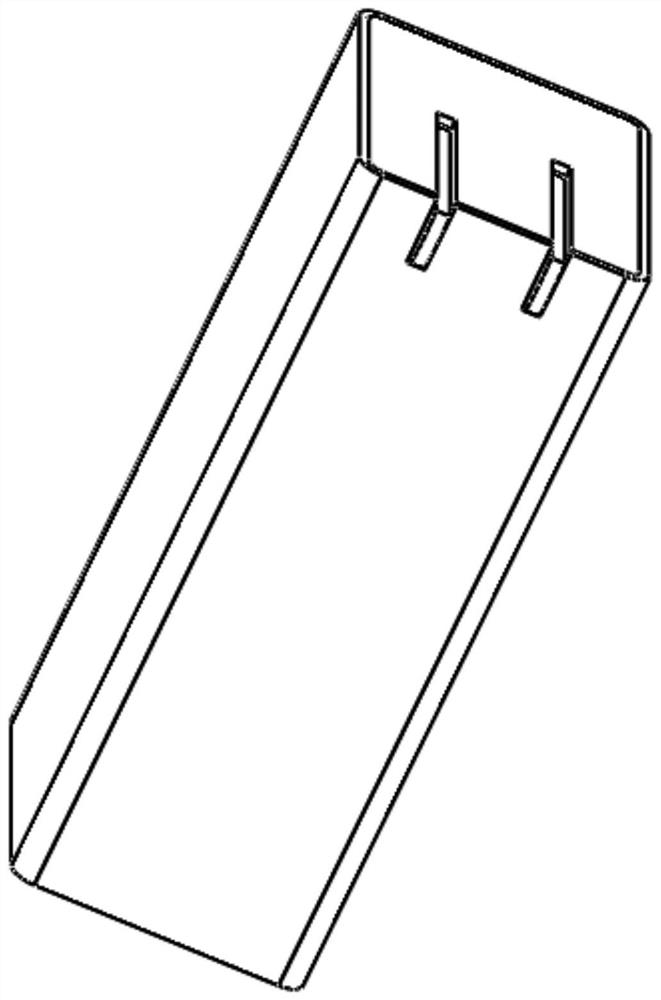

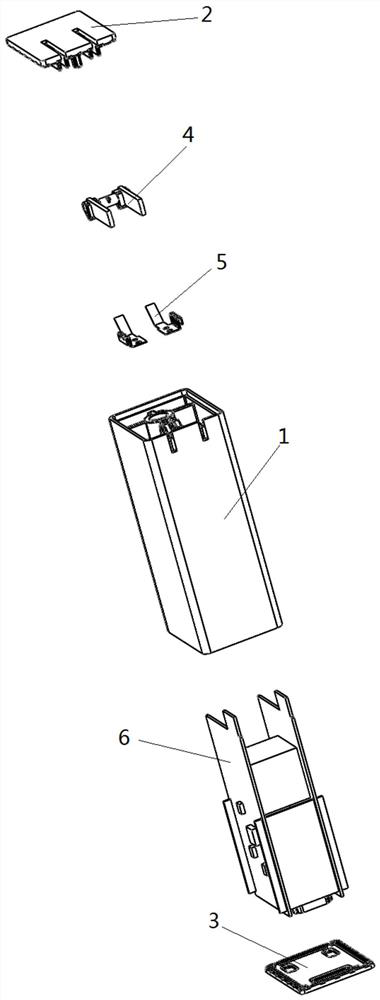

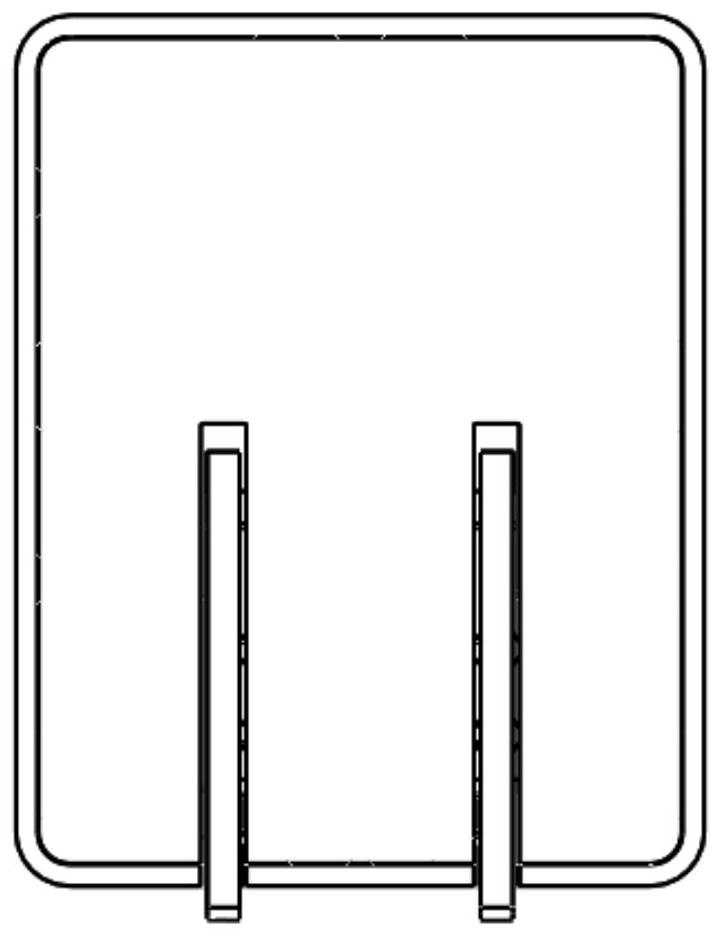

[0040] Such as Figure 1-11 The fast charging charger shown includes an upper cover 2 , a lower cover 3 , an AC plug 4 , a conductive shrapnel 5 , a PCB circuit board 6 and a housing body 1 .

[0041] A partition 7 is provided inside the housing main body 1 , so that the housing main body 1 is divided into an upper cavity and a lower cavity, and a conduction hole 11 is opened on the partition 7 . The PCB circuit board 6 includes a circuit board main body 601 and a circuit board connecting portion 602. The circuit board main body 601 is arranged in the lower cavity of the housing body 1, and the rest of the lower cavity is filled with a silica gel material (not shown in the figure). The material realizes good heat dissipation, and at the same time plays a role in fixing the circuit board and its electrical components; the circuit board connection part 602 is set through the conduction hole 11 of the interlayer 7, and the size, thickness and conduction of the circuit board conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com