Microneedle template and preparation method and application thereof

A technology of microneedle and template, applied in the direction of microneedle, needle, and other medical devices, etc., can solve the problems of difficulty in ensuring the uniform tip of the pinhole, affecting the sharpness of the tip of the pinhole, and difficult to prepare the sharpness of the tip. , to achieve the effect of low performance shrinkage, no physiological side effects, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

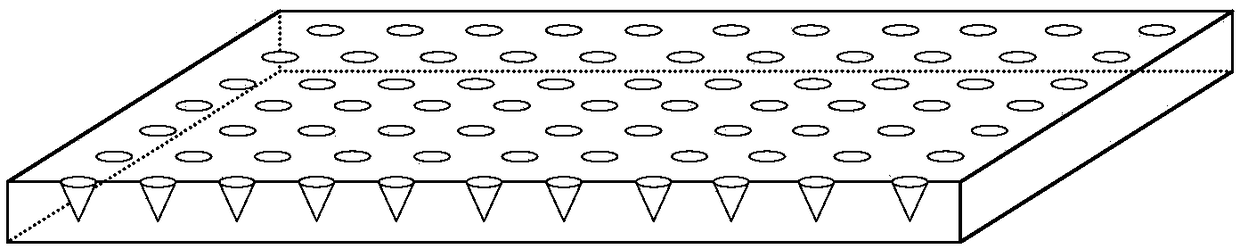

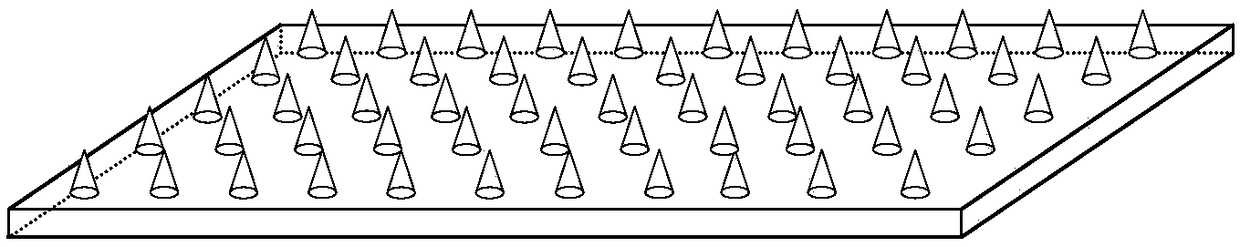

[0027] The microneedle template with a height of 300μm, a bottom diameter of 300μm, a pitch of 1700μm, and a 10×14 array is made as follows:

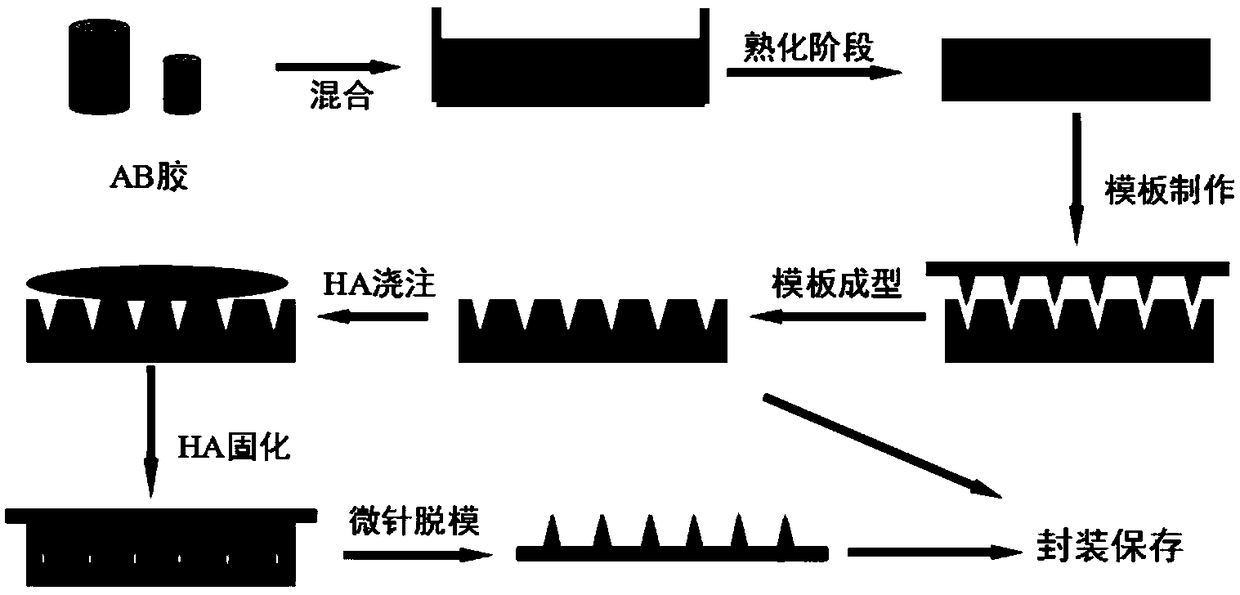

[0028] 1) Mix the low-molecular-weight bisphenol A epoxy resin adhesive (A) and the amine curing agent adhesive (B) at a mass ratio of 2.5:1, stir until the glue is completely transparent without wire drawing, and cure at 50°C for 90 minutes , Make it enter the maturation stage.

[0029] 2) Place the prepared metal microneedles on the epoxy resin film in the curing stage, press uniformly, and place them at room temperature for 5 hours to obtain a microneedle template with uniform thickness.

[0030] 3) Measure the thickness of the microneedle template obtained, place it in a package at room temperature for storage, and mark the size parameters of the microneedle template. The parameters of the aforementioned microneedle template are 300±10μm in height, 300±10μm in bottom diameter, 1700μm in pitch, and 10×14 microneedles in the array.

Embodiment 2

[0032] The height is 500μm, the bottom diameter is 500μm, the spacing is 1800μm, and the 10×14 array microneedle template is made. Proceed as follows:

[0033] 1) Mix the low molecular weight bisphenol A epoxy resin adhesive (A) with the amine curing agent adhesive (B) at a mass ratio of 3:1, stir until the glue is completely transparent without drawing inside, and cure at 70℃ for 1h , Make it enter the maturation stage.

[0034] 2) Place the prepared metal microneedles on the epoxy resin film in the curing stage, press uniformly, and place them at room temperature for 3 hours to obtain a microneedle template with uniform thickness.

[0035] 3) Measure the thickness of the microneedle template obtained, place it in a package at room temperature for storage, and mark the size parameters of the microneedle template. The parameters of the aforementioned microneedle template are 500±10μm in height, 500±10μm in base diameter, 1800μm in pitch, and 10×14 microneedles in the array.

[0036]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com