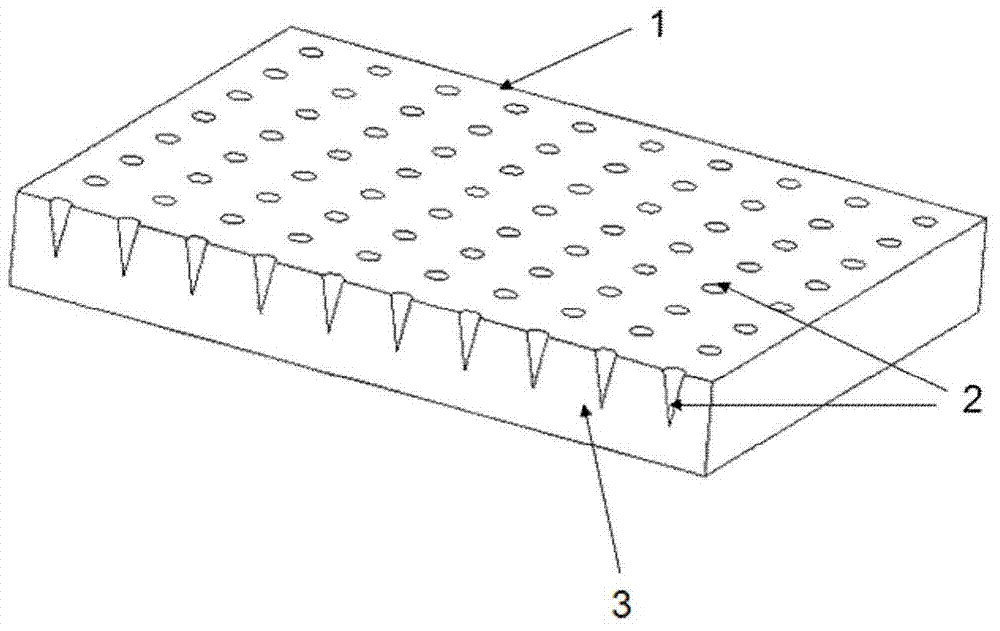

Microneedle template and preparation method thereof

A microneedle and template technology, applied in the directions of microneedles, needles, manufacturing tools, etc., can solve the problems of low preparation efficiency, complicated operation process, affecting the sharpness of the tip of the pinhole, etc., to achieve a simple and easy method, and the template is tough and durable. , good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

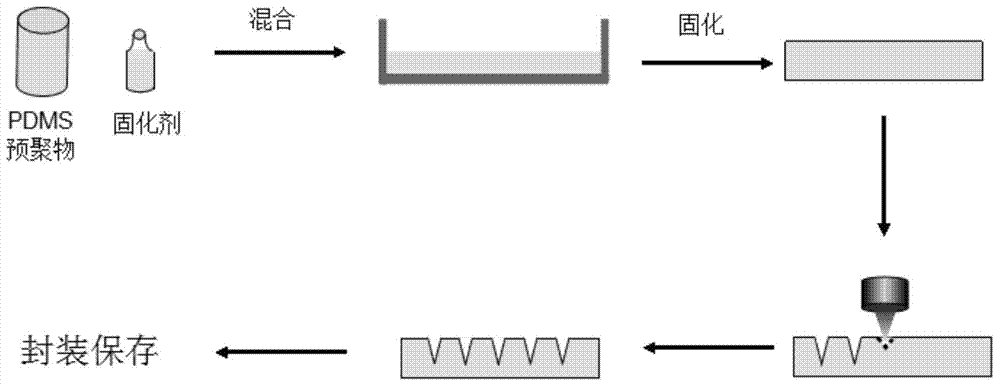

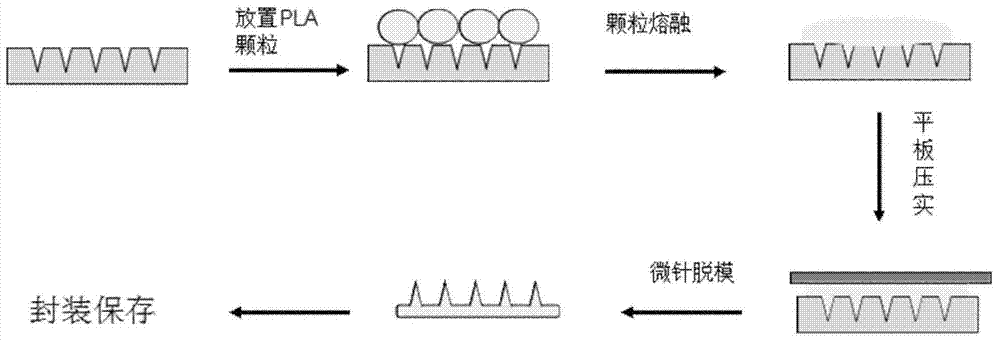

[0025] Preparation of microneedle templates with a height of 600 μm, a bottom diameter of 300 μm, a pitch of 0.5 mm, and a 10×10 array. The steps are as follows: 1) Preparation of polydimethylsiloxane film: weigh 150g of polydimethylsiloxane and 15g of aminoethylpiperazine curing agent to mix, stir evenly, remove air bubbles under vacuum conditions, and transfer to the bottom surface Put it in a smooth and flat container with a size of 40cm×20cm, place it horizontally, and cure it at 60°C for 6 hours to obtain a polydimethylsiloxane film with a thickness of 1.5mm and an area of 40cm×20cm as a template blank film, and package it for use; 2 ) Laser engraving: Cut the above-mentioned template blank film into a strip film with a width of 2cm and a length of 25cm, and put it into the laser engraving machine; turn on the laser engraving machine, and import a row of 12 red dot matrix with a distance of 150mm. The number of dots is 10×10, the distance between dots is 0.5mm, and the ...

Embodiment 2

[0027] Preparation of a microneedle template with a height of 400 μm, a bottom diameter of 200 μm, a microneedle spacing of 0.5 mm, and a 20×20 array. The steps are as follows: 1) Preparation of polydimethylsiloxane film: weigh 150g polydimethylsiloxane and 15g aminoethylpiperazine curing agent (this curing agent has added 1% dihydroconiferous cypress After adding base alcohol γ-O-α-L-rhamnoside, compared with no addition, its elasticity is improved and the service life is extended by 35%), mix well, remove air bubbles under vacuum conditions after stirring, and transfer to the bottom surface smooth and flat , in a container with a size of 40cm×20cm, placed horizontally, and cured at 60°C for 6 hours to obtain a polydimethylsiloxane film with a thickness of 1.5mm and an area of 40cm×20cm as a template blank film, which is packaged for use; 2) the Cut the above-mentioned polydimethylsiloxane film into a strip film with a width of 2 cm and a length of 25 cm, and put it into a ...

Embodiment 3

[0029] Preparation of a microneedle template with a height of 1000 μm, a bottom diameter of 280 μm, a microneedle spacing of 0.8 mm, and a 5×5 array.

[0030] The steps are as follows: 1) Preparation of polydimethylsiloxane film: Weigh 150g of polydimethylsiloxane and 15g of diaminodiphenyl sulfone curing agent to mix, stir evenly, remove air bubbles under vacuum conditions, transfer to the end Put it in a container with a smooth surface and a size of 40cm×20cm, place it horizontally, and cure it at 60°C for 6 hours to obtain a polydimethylsiloxane film with a thickness of 1.5mm and an area of 40cm×20cm as a template blank film, and package it for use; 2) Cut the above-mentioned polydimethylsiloxane film into a strip film with a width of 2 cm and a length of 25 cm, and put it into a laser engraving machine; turn on the laser engraving machine, and import a row of 12 red dots with a distance of 150 mm. The number of lattice points is 20 × 20, the point spacing is 0.8mm, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com