Low-hydroxyl opaque quartz glass and manufacturing method thereof

A technology of transparent quartz and manufacturing methods, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of lack of low-hydroxyl opaque quartz glass materials, etc., and achieve low metal impurity content and good micropore uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] 1) Prepare a green body.

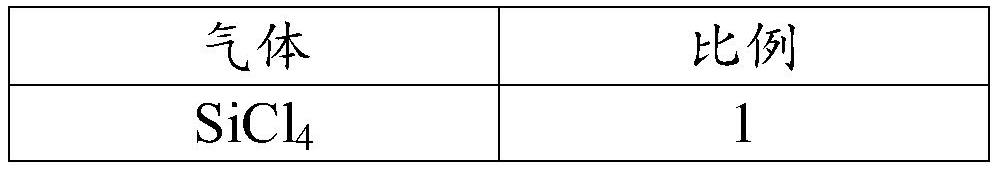

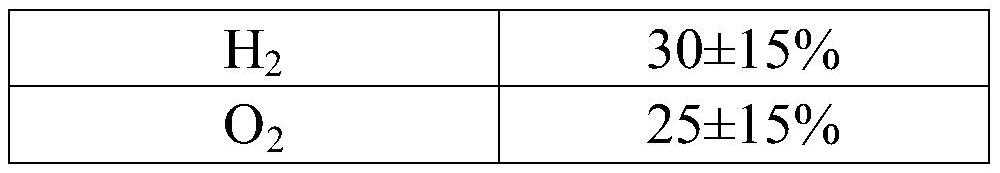

[0076] Choose SiCl 4 is the silicon source, H 2 for heat source.

[0077] The SiCl 4 The liquid is passed into the evaporative gasification device, which does not belong to the content of the present invention and is purchased from outside. Set the gasification temperature to 95°C, use a constant temperature pipeline to connect the gasification device to the reactor, and set the pipeline temperature to 95°C to avoid SiCl 4 liquefaction. SiCl 4 The inflow is accurately measured by a mass flow meter to control the reaction process and improve the utilization of Si source.

[0078] Hydrogen and oxygen were fed into the reactor, and a mass flow meter was used to accurately measure the incoming amount.

[0079] The above three gases react chemically in the reactor to generate SiO 2 , the reaction principle is as follows:

[0080] SiCl 4 +2H 2 +O 2 =SiO 2 +4HCl

[0081] In the present embodiment, the reaction volume ratios of the three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com