Plastic package stator runner-free mold

A plastic-encapsulated stator without runner technology, applied in the field of molds, can solve problems affecting the health of operators, affecting the quality of plastic sealing parts, affecting the appearance, etc., to achieve the effect of facilitating pressure transmission, solving the problem of dust treatment, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

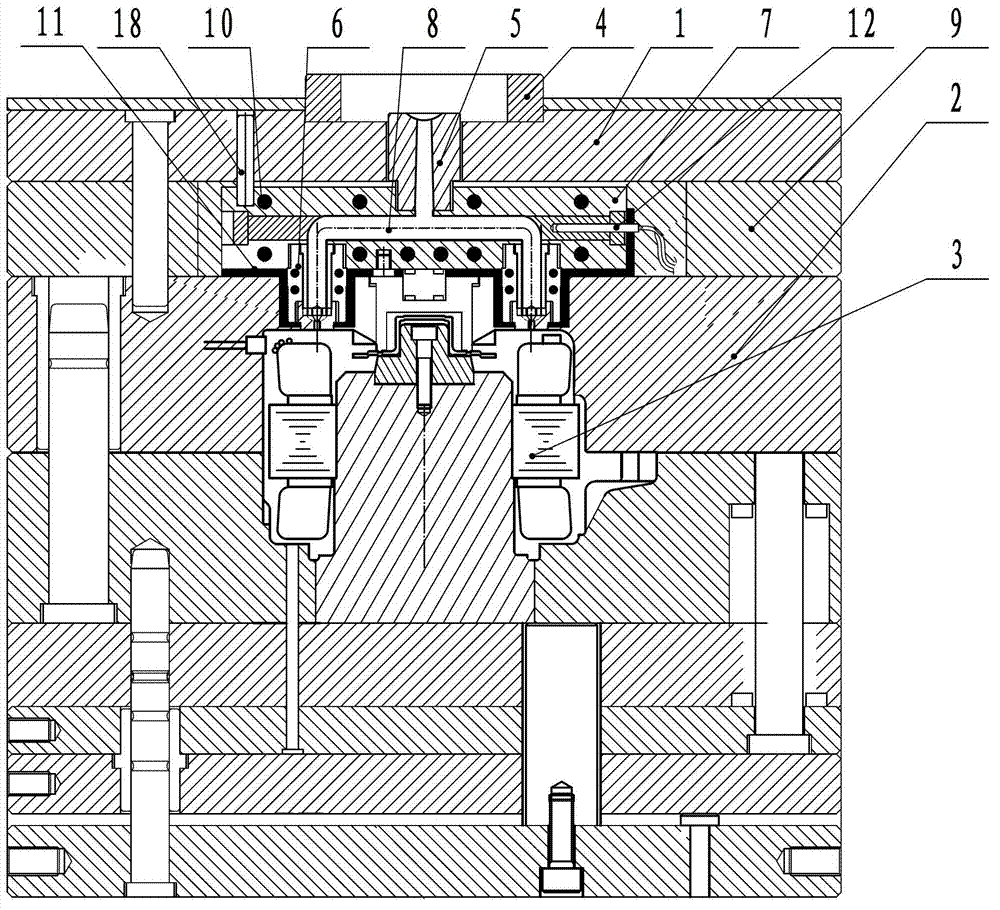

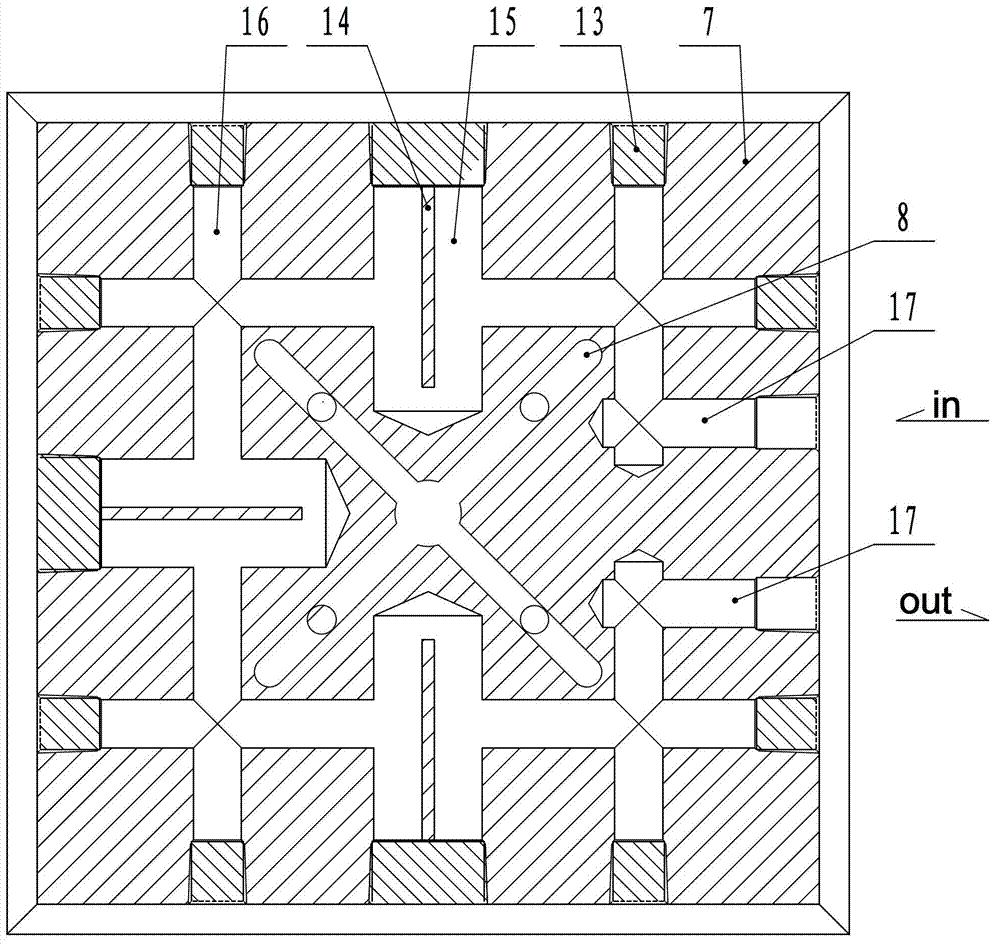

[0019] like figure 1 As shown, it includes a movable mold and a fixed mold. The fixed mold includes a fixed mold seat plate 1 and a fixed mold plate 2 for opening a stator cavity 3. It is characterized in that: the positioning ring 4 in the middle position of the fixed mold seat plate 1 and the positioning ring 4 Concentric main filling nozzle 5, fixed template 2 is provided with an upward feeding cavity, embedded in the feeding cavity is cold filling nozzle 6, a runner plate 7 is provided between the fixed mold seat plate 1 and the fixed template 2, and the flow channel The plate 7 is provided with a cold runner 8 passing through the main filling nozzle 5 and the cold filling nozzle 6, and the two sides of the runner plate 7 are provided with feet 9 higher than the runner plate 7; A cooling channel 10 is provided, and a heat insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com