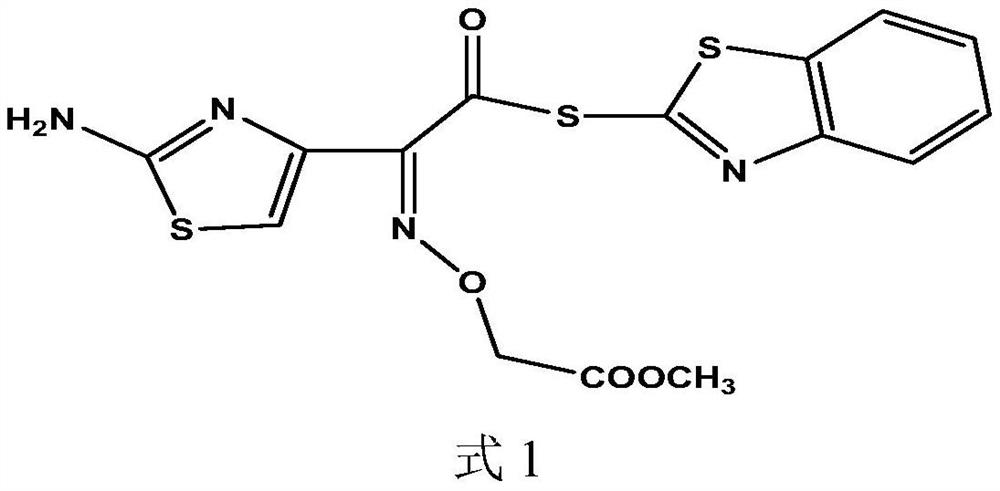

Method for continuously synthesizing cefixime side chain acid active ester

A technology of cefixime side chain acid and active ester, applied in the field of medicine, can solve the problems of long residence time of materials, poor product quality uniformity, poor energy utilization rate, etc., achieve stable heat release, easy temperature control, and reduce VOC The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

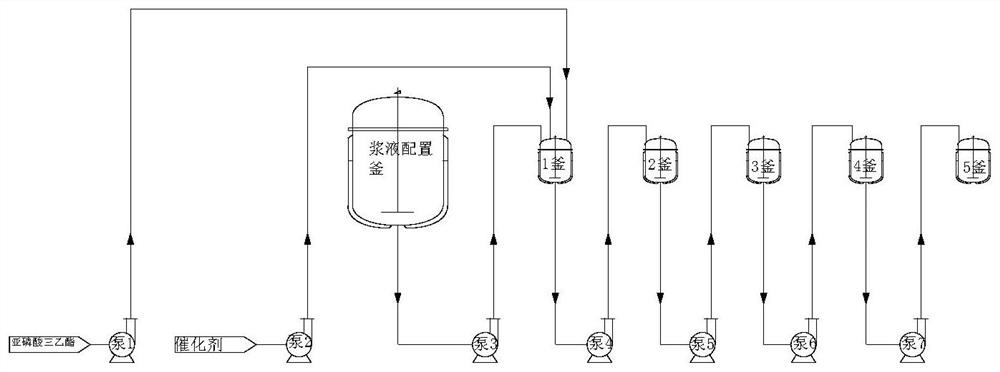

Embodiment 1

[0037] The side chain acid active ester of cefixime was synthesized by a three-stage serial tank reactor, each reactor had a volume of 5 L, and each reactor was connected in series by a metering pump. In the slurry configuration kettle of 50L, cefixime side chain acid: dithiodibenzothiazole: acetonitrile is added by weight ratio 1:1.4:8.0, starts to stir, presses 200g / min by metering pump, simultaneously catalyst (three The weight ratio of ethylamine: pyridine: dimethylaniline is 1:0.2:0.3) according to the weight ratio of 0.025:1 to the slurry, the catalyst is added through the metering pump at a speed of 5g / min, and then added to the first-stage reaction kettle. According to the weight ratio of triethyl phosphate to the slurry of 0.078:1, add triethyl phosphite through the metering pump at a speed of 15.5g / min, and then add it to the first-stage reaction kettle; The feed liquid of the first-stage reactor is added to the second-stage reactor, and after 40 minutes, the feed li...

Embodiment 2

[0039]The side chain acid active ester of cefixime was synthesized by a three-stage serial tank reactor, each reactor had a volume of 5 L, and each reactor was connected in series by a metering pump. In the slurry configuration kettle of 50L, cefixime side-chain acid: dithiodibenzothiazole: acetonitrile is added by weight ratio 1:1.4:8.0, starts to stir, presses 133g / min by metering pump, simultaneously catalyst (three The weight ratio of ethylamine:pyridine:dimethylaniline is 1:0.2:0.3) according to the weight ratio of the slurry to 0.025:1, the catalyst is added through the metering pump at a speed of 3.3g / min, and added to the first-stage reaction kettle, while According to the weight ratio of triethyl phosphite to the slurry of 0.078:1, add triethyl phosphite through the metering pump at a speed of 10.4g / min, and then add it to the first-stage reaction kettle; The feed liquid of the first-stage reactor is added to the second-stage reactor, and after 60 minutes, the feed li...

Embodiment 3

[0041] The side chain acid active ester of cefixime was synthesized by a three-stage serial tank reactor, each reactor had a volume of 5 L, and each reactor was connected in series by a metering pump. In the slurry configuration kettle of 50L, cefixime side chain acid: dithiodibenzothiazole: acetonitrile is added by weight ratio 1:1.4:8.0, starts to stir, presses 100g / min by metering pump, simultaneously catalyst (three The weight ratio of ethylamine: pyridine: dimethylaniline is 1:0.2:0.3) according to the weight ratio of the slurry to 0.025:1, the catalyst is added through the metering pump at a speed of 2.5g / min, and added to the first-stage reaction kettle, and at the same time According to the weight ratio of triethyl phosphite to the slurry of 0.078:1, add triethyl phosphite through the metering pump at a speed of 7.8g / min, and then add it to the first-stage reaction kettle; The feed liquid of the first-stage reactor is added to the second-stage reactor, and after 60 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com