Copper electrolyte decoppering method by utilizing copper electrolytic residual anodes as cathodes and device thereof

A technology of copper electrolysis and butt anode, applied in the field of copper electrolysis, can solve the problems of lead anode lug burning, increase of manpower, material and financial resources in copper electrolyte decopper process, starting electrode piece and cathode ear breaking, etc., so as to improve production efficiency , Reducing the rate of scrap anode returning to the furnace, and the effect of compact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method of the present invention will be further described below by means of the accompanying drawings and examples.

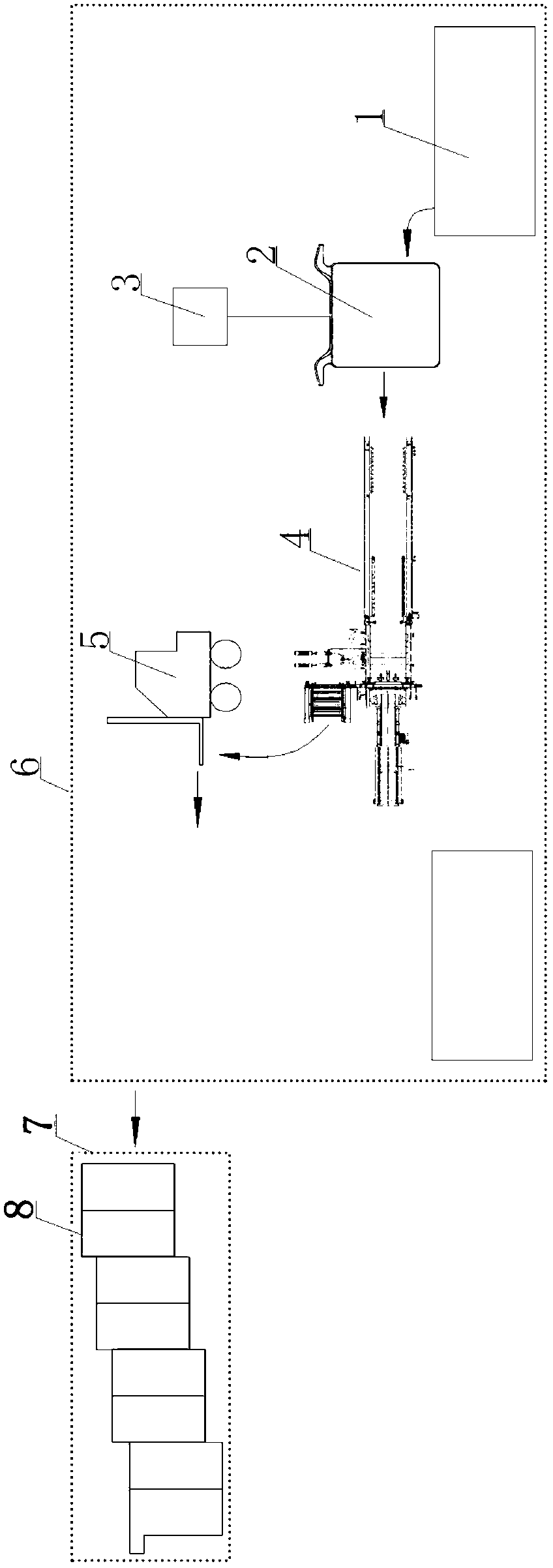

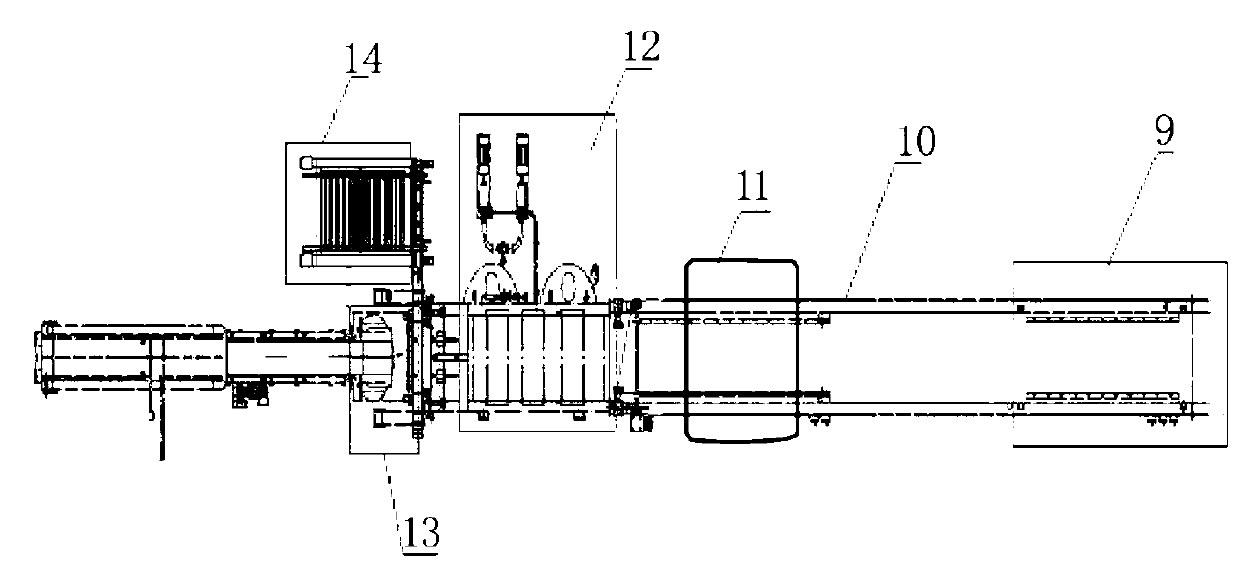

[0018] Such as figure 1 and figure 2 As shown, after the electrolysis of the copper anode plate in the copper electrolytic cell is completed, the copper electrolytic residual anode 2 is hoisted out from the electrolytic tank 1 in the electrolytic workshop 6 by the crane 3 and sent to the copper electrolytic residual anode washing unit 4 with the plate selection function The anode residue receiving station 9, the anode residue transfer trolley 11 running on the transfer vehicle track 10 transports the copper electrolysis anode residue 2 to the anode residue washing room 12 for cleaning, and the cleaned copper electrolysis anode residue 2 enters the anode residue transition device 13. The operator selects the residual anodes 2 of the copper electrolysis, and then transports them out by the running trolley 14 in a suspended and closely arranged manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com