Replaceable battery feeding and discharging waterwheel assembly

A technology of waterwheels and components, applied in the direction of transportation, packaging, conveyors, etc., can solve problems affecting product quality, affecting production efficiency, and cumbersome processes, and achieve the effects of facilitating production automation, improving production efficiency, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

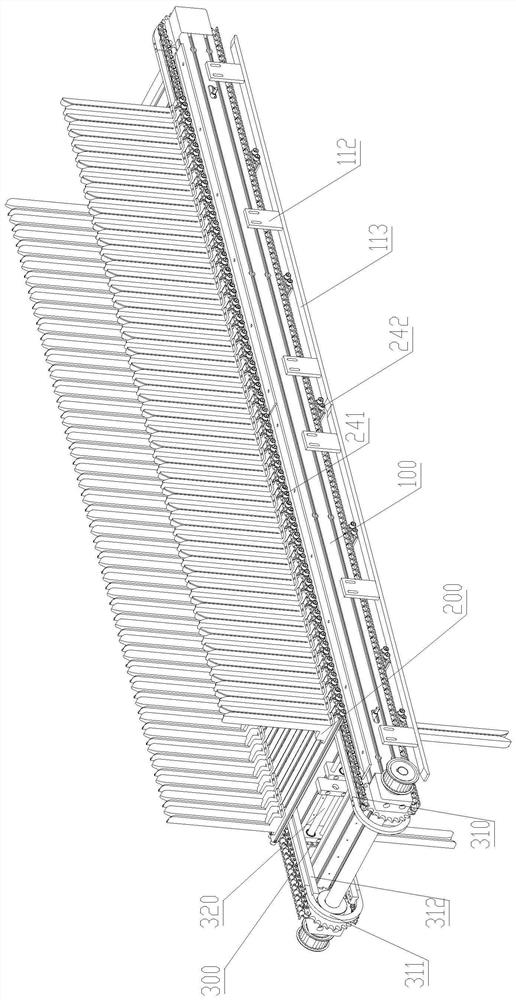

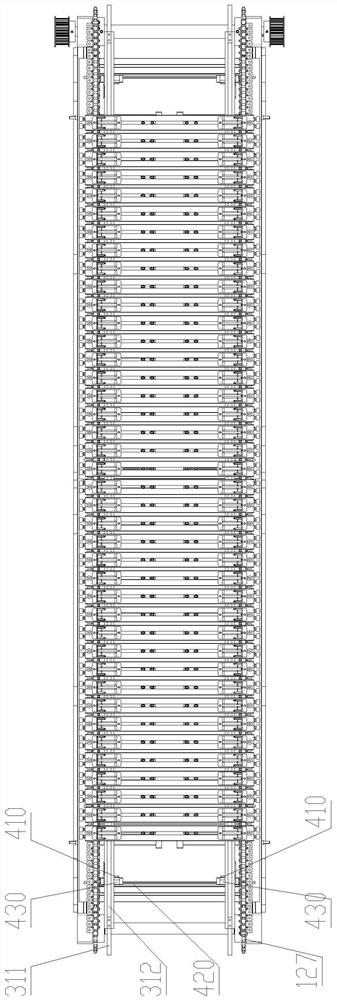

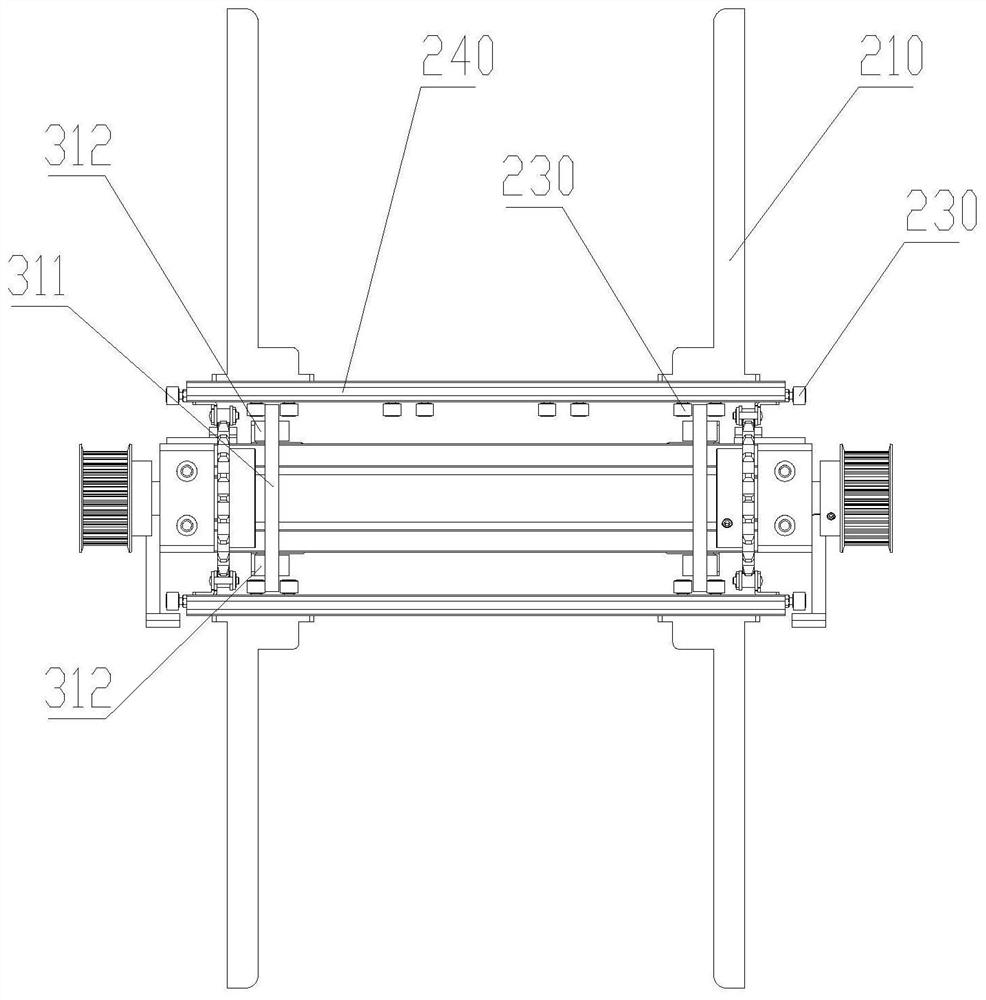

[0024] Embodiment 1 A replaceable battery loading and unloading water truck assembly described in the present invention includes:

[0025] The water wheel main body assembly 100 includes a support mechanism 110 and a double-speed chain conveying mechanism 120. The support mechanism 110 has two opposite and parallel support wire bodies for supporting the double-speed chain conveying mechanism and other components; to support the length of the wire body The direction is the longitudinal direction, and the width direction of the support mechanism is the transverse direction; the double-speed chain conveying mechanism 120 includes a driving conveying part, a driven conveying part and a double-speed chain 124, and the driving conveying part and the driven conveying part are rotatable respectively. It is arranged at both ends of the support line body in the longitudinal direction, and the double-speed chain 124 is arranged around the driving conveying part and the driven conveying pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com