Six-axis carrying mechanical arm for battery burn-in board

A technology of six-axis manipulator and burn-in plate, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency, easy to scratch the battery, and high defective rate of the battery, so as to improve production efficiency, optimize battery quality, and benefit The effect of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

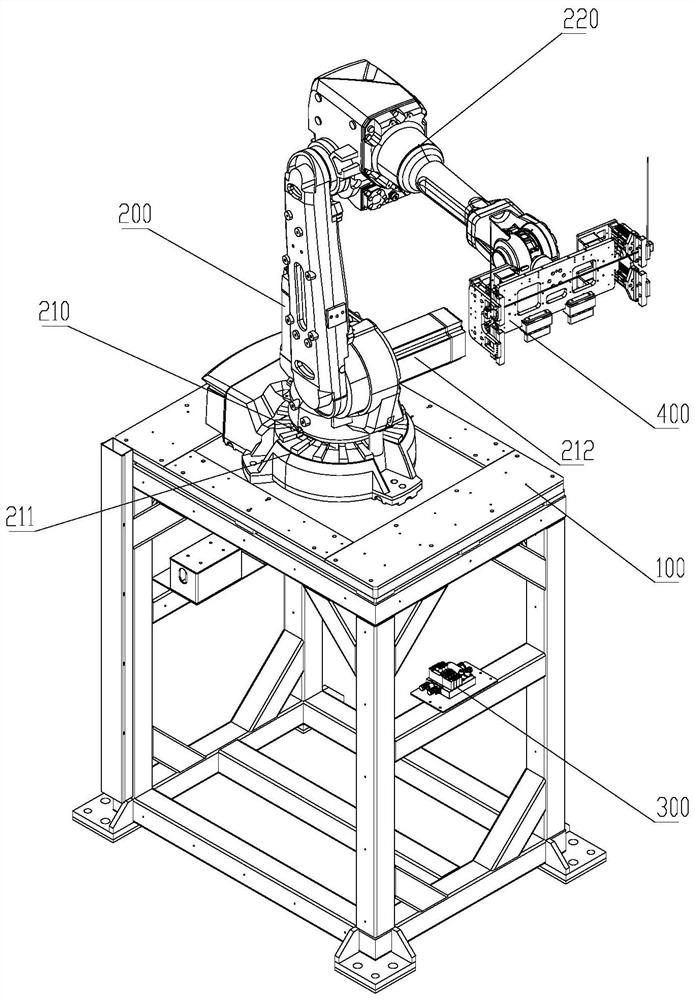

[0013] Embodiment 1 The present invention proposes a six-axis handling manipulator for battery aging boards, including a base 100, a six-axis manipulator 200, a control mechanism 300, and a clamping mechanism 400. The base 100 is a frame structure, and its bottom can be fixed on other installation surfaces; the six-axis manipulator 200 and the control mechanism 300 are installed on the base 100, and the signal output end of the control mechanism 300 is connected to the control end of the six-axis manipulator 200, the The control end of the clamping mechanism 400 is electrically connected to control the work of the six-axis manipulator and the clamping mechanism;

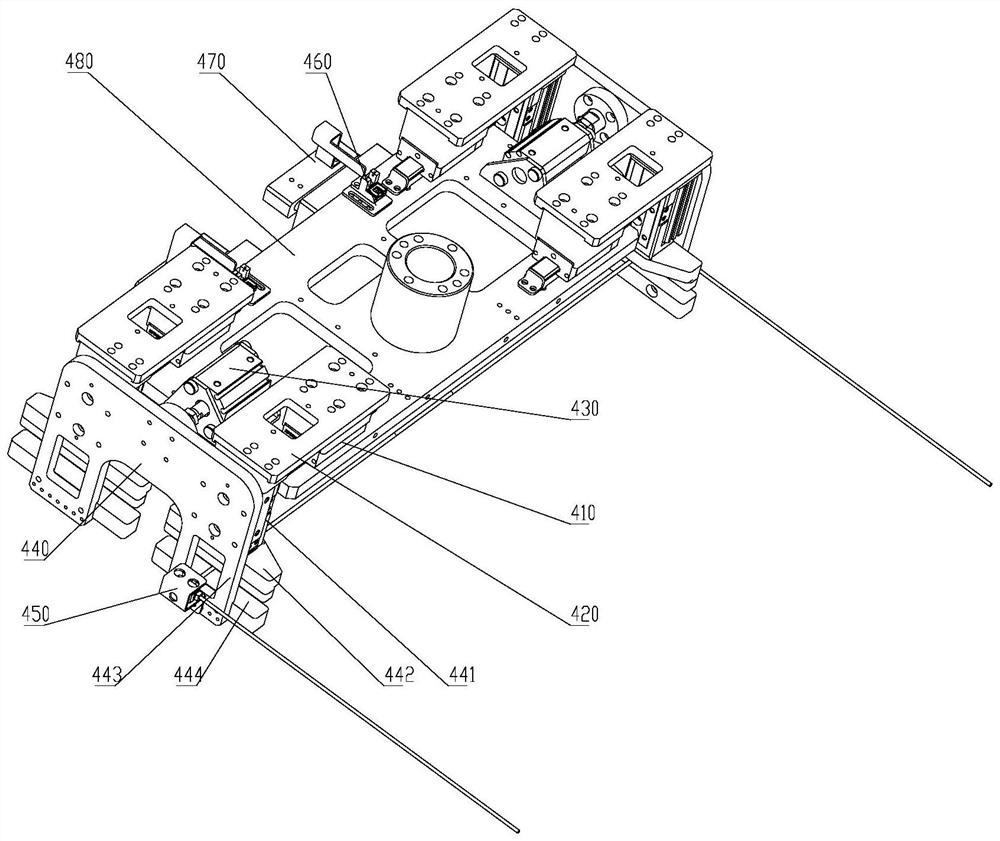

[0014] The clamping mechanism 400 is used to clamp or release the burn-in plate, and is installed on the movable end of the six-axis manipulator 200, including a main connecting plate 480, a transverse driving device 430 and a pair of clamping devices 440. The plate 480 is fixedly installed on the movable end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com