Power pouch battery exhausting and sealing clamp and exhaust sealing method

A technology of soft-pack batteries and sealing clips, which is applied to electrical components, secondary batteries, battery assembly machines, etc. It can solve problems such as battery side sealing, air bag bulging, battery damage, etc., to improve performance parameters and improve production Efficiency, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 A power pouch battery exhaust sealing fixture according to the present invention includes:

[0041] The installation bracket 100 is provided with an installation space for installing the cylinder power mechanism, the exhaust fixture and the heating and sealing fixture;

[0042] The cylinder power mechanism 200 includes a cylinder assembly, a plug and a cylinder fixing block, the cylinder assembly is installed on the upper part of the bracket body through the cylinder fixing block, and the plug is installed on the telescopic part of the cylinder assembly, and is used to control the exhaust clamp and the heating and sealing clamp. clamp and open;

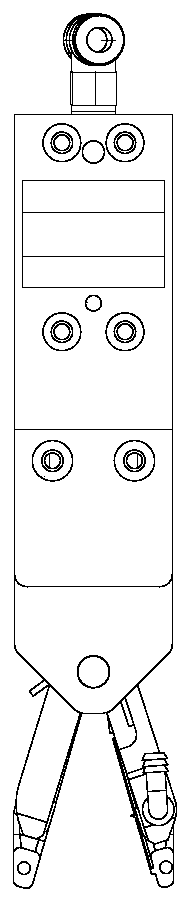

[0043] The exhaust clamp 300 includes an exhaust clamp body, a piercing part and a sealed exhaust part. The exhaust clamp body is hinged on the mounting bracket below the cylinder power mechanism. The upper part is the clamping degree adjustment end for plug insertion, and the lower part is The battery clamping end;...

Embodiment 2

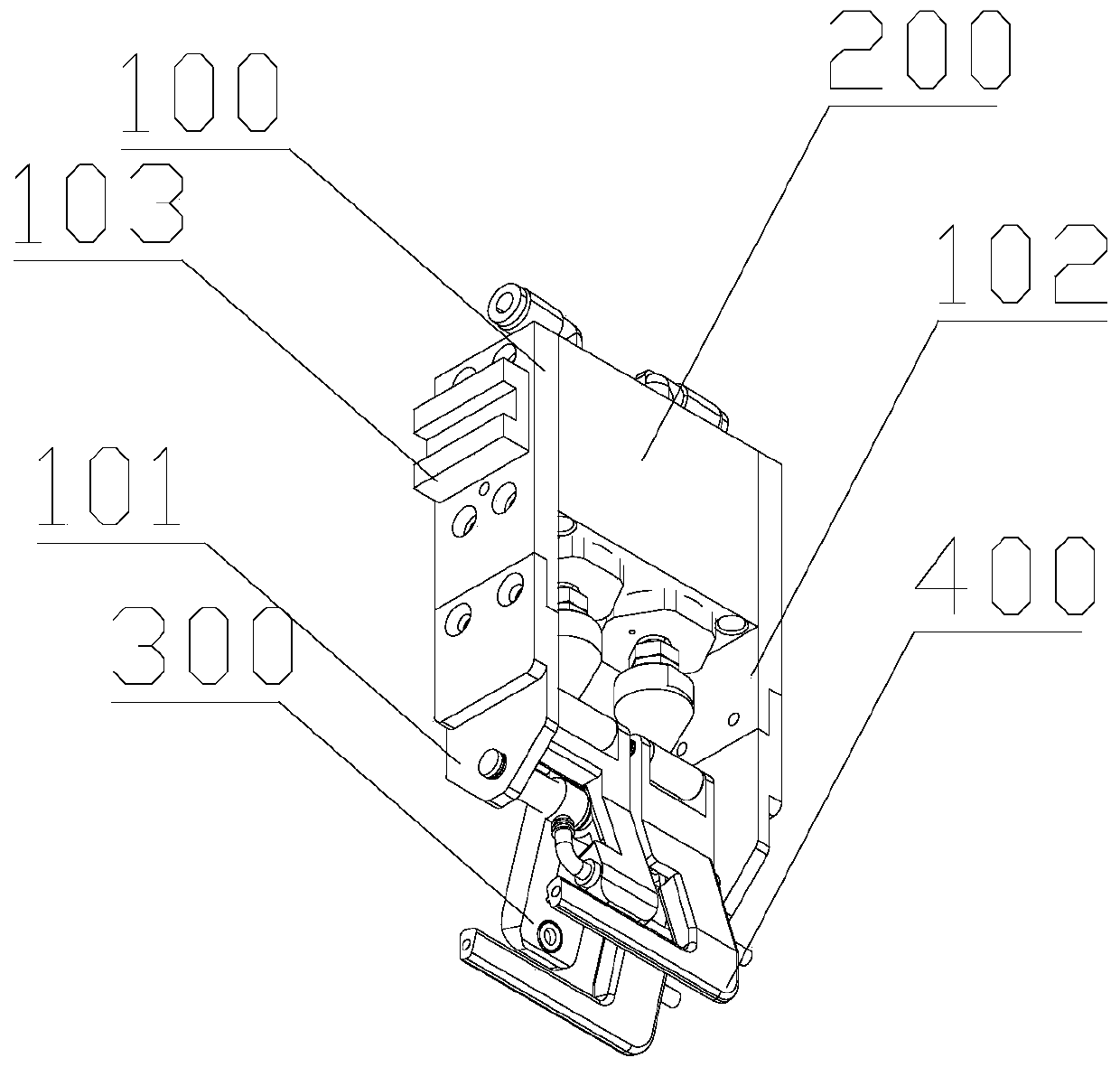

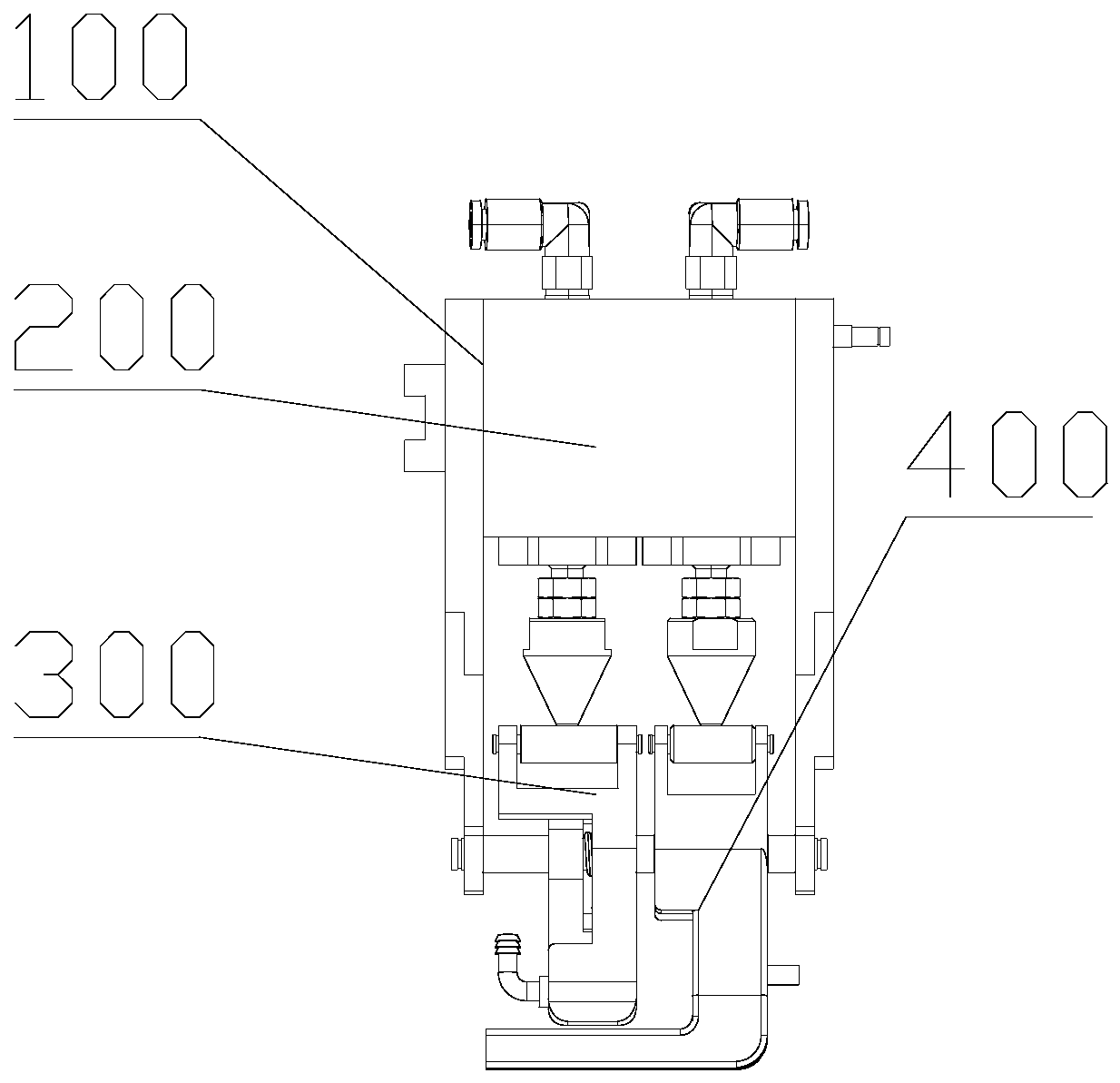

[0055] Example 2 as Figure 1a-1c The illustrated power pouch battery exhaust sealing fixture includes a mounting bracket 100 , a cylinder power mechanism 200 , an exhaust fixture 300 and a heating sealing fixture 400 . The cylinder power mechanism 200, the exhaust fixture 300 and the heating and sealing fixture 400 are fixed on the mounting bracket 100, and the exhaust fixture 300 and the heating and sealing fixture 400 are arranged on the telescopic end movement track of the cylinder power mechanism 200 superior.

[0056] As shown in FIGS. 1 and 2 , the cylinder power mechanism 200 includes a cylinder assembly 201 , a plug 202 and a cylinder fixing block 203 . The air cylinder power mechanism 200 controls the clamping and opening of the exhaust clamp 300 and the heating and sealing clamp 400 .

[0057] Such as Figures 3a-3c The exhaust clamp 300 shown includes a exhaust clamp body, a piercing part and a sealing exhaust part, and the exhaust clamp body includes a pair of ...

Embodiment 3

[0063] Embodiment 3 The method for performing exhaust sealing by using the exhaust sealing fixture of a power pouch battery described in Embodiment 1 includes the following steps:

[0064] 1) Adjust the position of the exhaust sealing fixture so that the battery air bag is placed at the opening of the exhaust fixture and the sealing fixture;

[0065] 2) Exhaust: Start the first set of cylinder assembly, so that the plug is gradually inserted into the exhaust clamping degree adjustment device at the end of the exhaust clamp body, so that the exhaust clamp body clamps the battery air bag, and then use the piercing needle 303 Puncture and exhaust the battery air bag; adjust the exhaust speed by adjusting the size of the negative pressure;

[0066] 3) Sealing: After the exhaust is completed, the second set of cylinder components starts to work, so that the corresponding plug is gradually inserted into the sealing clamping degree adjustment device at the end of the sealing clamp bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com