Method for continuously synthesizing ethyl 2-(2-aminothiazole-4-yl)-2-methoxyiminoacetate

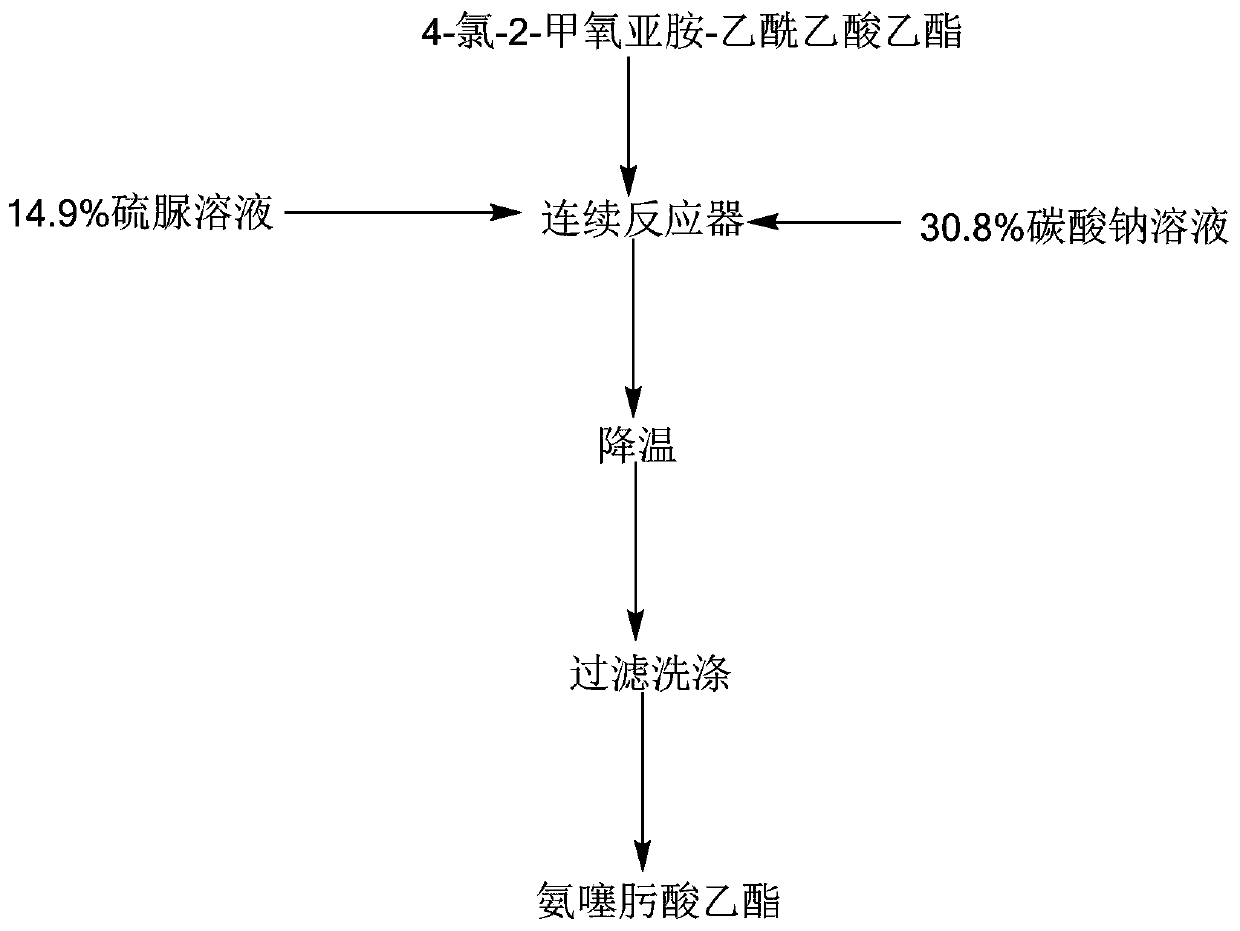

A technology of ethyl aminothiaxamate and ethyl methoxyiminoacetoacetate, which is applied in the field of drug synthesis, can solve the problems of unstable product quality, large amount of thiourea added, and large fluctuation of yield, and achieve easy production automation and continuous progress. The effect of easy feeding and discharging, temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

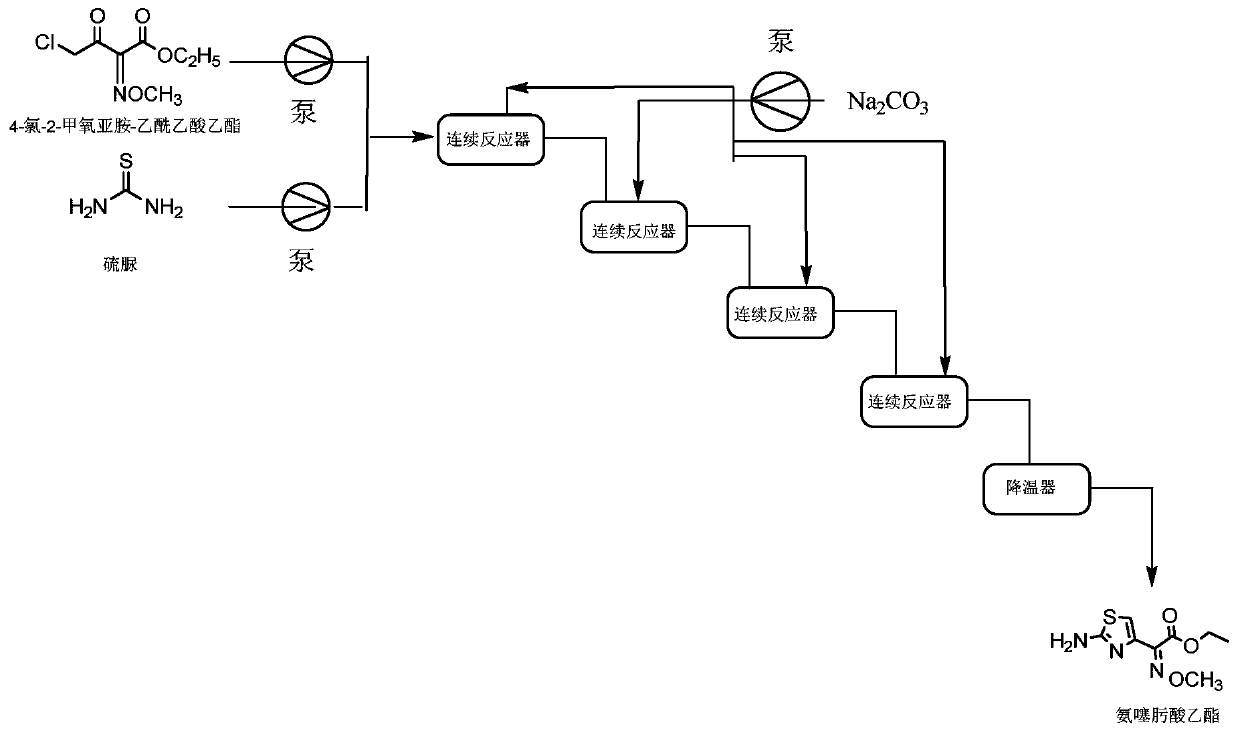

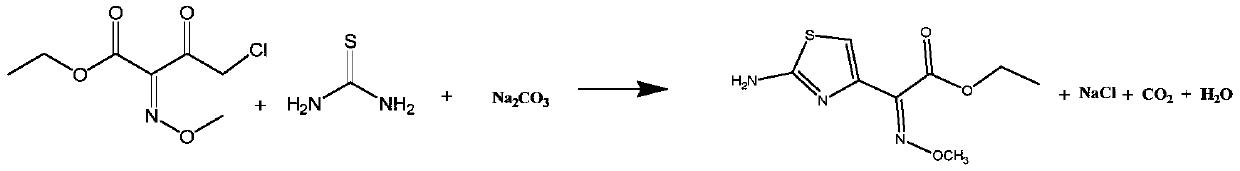

[0029] Set 4-chloro-2-hydroxyimine-ethyl acetoacetate (concentration 68%, see Table 1 for liquid phase purity, solvent is aqueous methanol, methanol: water mass ratio=1.45:1, dilute to 68% by liquid phase pump % use) flow rate 3.95g / min, thiourea solution (concentration 14.9%, solvent is methanol aqueous solution, methanol: water mass ratio=1.45:1) flow rate 6.70g / min, flow rate ratio is 1:1.7 and pumped into continuous reaction Reaction in the reactor, the continuous reactor is a 4-stage overflow device, each overflow device is a reaction bottle with a volume of 1000ml; the temperature is controlled at 35-40°C, and the soda ash solution is added dropwise to the reaction by using a peristaltic pump according to the pH change in the reaction bottle In the bottle, the pH is controlled at 4.5-6. After 4 hours of reaction, it overflows to the cooling device, cools down to 15-20°C, filters, washes with 80% methanol solution, and obtains ethyl aminothiaxate, and runs continuously for...

Embodiment 2

[0033] Set 4-chloro-2-hydroxyimine-ethyl acetoacetate (concentration 65%, liquid phase purity see Table 2, solvent is methanol aqueous solution, methanol: water mass ratio=1.45:1) reaction liquid 2.63 by liquid phase pump g / min, thiourea solution (concentration 14.9%, solvent is methanol aqueous solution, methanol: water mass ratio=1.45:1) flow rate 4.71g / min, flow rate ratio is 1:1.8 to pump together in the continuous reactor reaction, continuous The reactor is a 3-stage overflow device, and the temperature is controlled at 35-40°C. According to the pH change in the reaction bottle, the soda ash solution is added dropwise into the reaction bottle using a peristaltic pump, and the pH value is controlled at 4.5-6. After 5 hours of reaction, it enters the cooling device. Control the temperature at 15-20°C, filter, wash with methanol solution with a concentration of 80%, and obtain the pure product of ethyl thioxamate, and run continuously for 24 hours to obtain 2509.1g of pure pr...

Embodiment 3

[0037] Set 4-chloro-2-hydroxyimine-ethyl acetoacetate (concentration 65%, see Table 3 for liquid phase purity, solvent is methanol aqueous solution, methanol: water mass ratio=1.45:1) reaction liquid 3.95 g / min, thiourea solution (concentration 14.9%, solvent is aqueous methanol, methanol: water mass ratio=1.45:1) flow rate 5.93g / min, flow rate ratio is 1:1.5 pumped into the continuous reactor together to react, continuous The reactor is a three-stage overflow device, and the temperature is controlled at 35-40°C. According to the pH change in the reaction bottle, the soda ash solution is added dropwise into the reaction bottle with a peristaltic pump. The pH value is controlled at 4.5-6, and it enters the cooling device after 4.5 hours of reaction. , the temperature is controlled at 15-20°C, filtered, washed with methanol solution with a concentration of 80%, and the pure product of ethyl thioxamate is obtained. After continuous operation for 12 hours, 1875.8g of the pure produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com