Air conditioner fan coil pipe water receiving tray production method

A production method, air-conditioning fan technology, applied in the direction of coating, etc., can solve the problems of laborious transportation and replacement, high production cost, and easy desoldering, so as to avoid metal and non-metal impurities, simple processing and forming process, and conducive to production The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment specifically discloses a method for producing an air-conditioning fan coil water tray, including the following steps:

[0074] 1) Add the raw material components of the air-conditioning fan coil water tray into the mixer for preliminary mixing to obtain a premix; the initial mixing time is 12 hours, so that the preliminary mixing is uniform;

[0075] 2) The premix is added into a screw extruder through a feeder to extrude and granulate to obtain modified plastic particles; the screw speed of the feeder is 60r / min; the screw extruder is a three-stage single-screw Extruder, the first two-stage screw extruder is used for material transportation and compression melting mixing, and the last-stage screw extruder is used for uniform plasticization and melt transportation of the melt; the screw diameter of the first-stage screw extruder is 125mm, length-to-diameter ratio is 25; the screw speed of the first-stage screw extruder is 160r / min, and the heating temp...

Embodiment 2

[0085] This embodiment specifically discloses a method for producing an air-conditioning fan coil water tray, including the following steps:

[0086] 1) Add the raw material components of the air-conditioning fan coil water tray into the mixer for preliminary mixing to obtain a premix; the initial mixing time is 12 hours;

[0087] 2) The premix is added into a screw extruder through a feeder to extrude and granulate to obtain modified plastic particles; the screw speed of the feeder is 70r / min; the screw extruder is a three-stage single-screw Extruder, the first two-stage screw extruder is used for material transportation and compression melting mixing, and the last-stage screw extruder is used for uniform plasticization and melt transportation of the melt; the screw diameter of the first-stage screw extruder is 125mm, length-to-diameter ratio is 25; the screw speed of the first-stage screw extruder is 160r / min, and the heating temperature is 230-250°C; the discharge end of ...

Embodiment 3

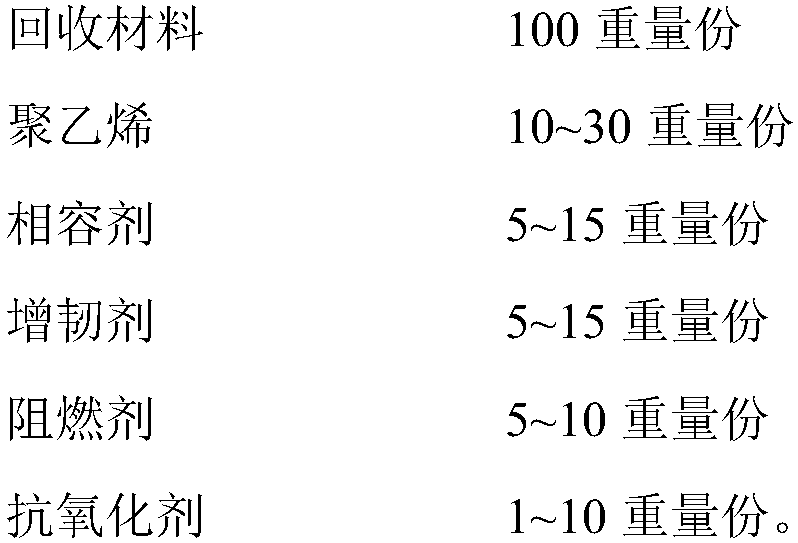

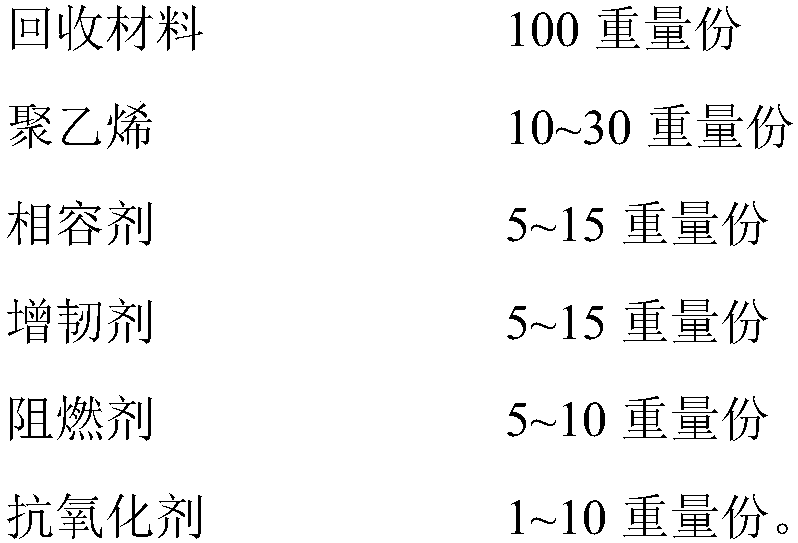

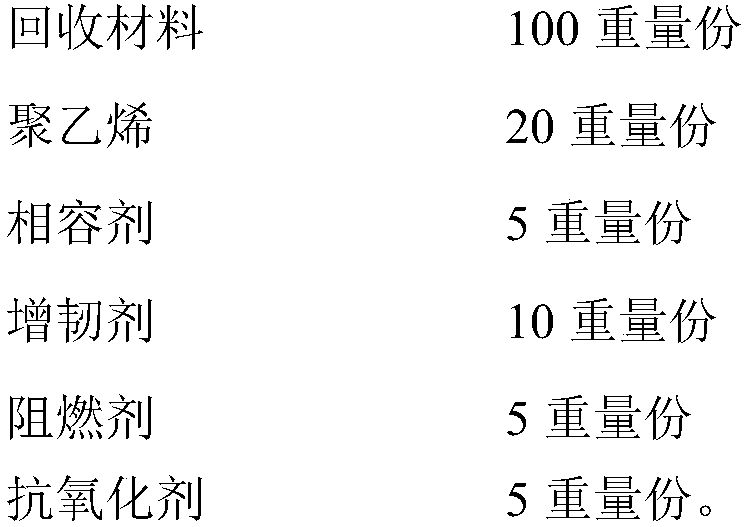

[0111] In this embodiment, the air-conditioning fan coil water receiving tray includes the following raw material components and parts by weight:

[0112]

[0113] Wherein, the polyethylene is high-density polyethylene, and the number-average molecular weight of the high-density polyethylene is 10,000-20,000.

[0114] The compatibilizer is maleic anhydride grafted polyethylene, and the graft ratio of the maleic anhydride grafted polyethylene is 0.5%-0.9%.

[0115] The toughening agent is methyl methacrylate-butadiene-styrene terpolymer.

[0116] The flame retardant is tris(2,4-dibromophenyl) phosphate.

[0117] The antioxidant is hindered phenolic antioxidant, specifically antioxidant 1024.

[0118] This embodiment specifically discloses a method for producing an air-conditioning fan coil water tray, including the following steps:

[0119] 1) Add the raw material components of the air-conditioning fan coil water tray into the mixer for preliminary mixing to obtain a prem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com