Finished product steel strand bundle with fixable carding board

A steel strand harness and fixed comb technology, which is applied in the field of prestressed steel strand and finished steel strand harness, can solve the problems that steel strands are prone to entanglement or crossing, and achieve high construction efficiency and avoid entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

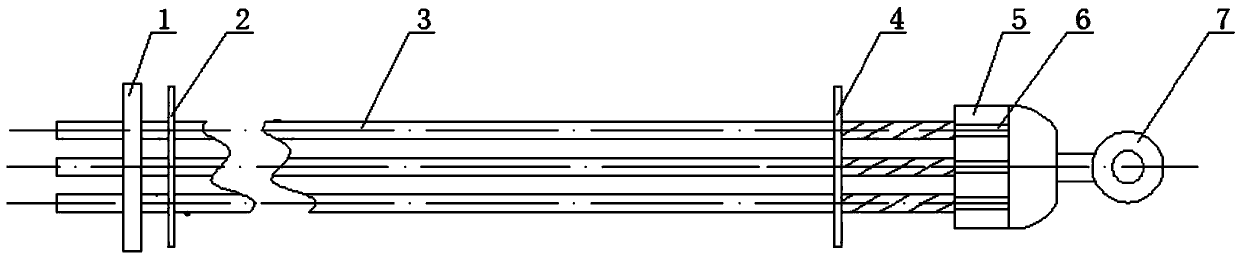

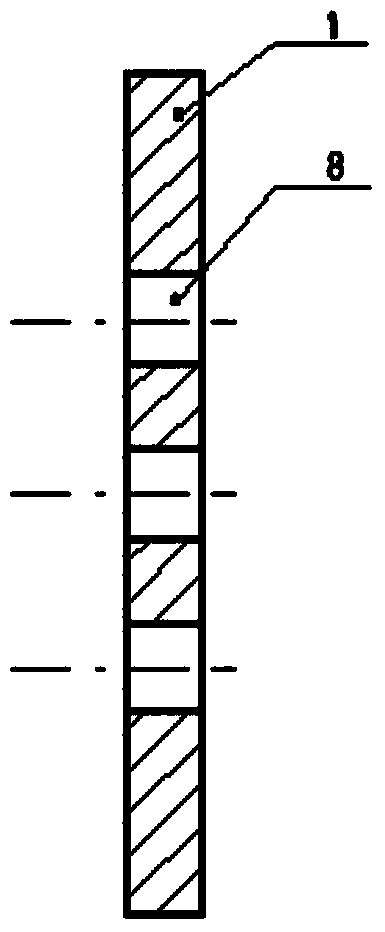

[0017] A finished steel strand bundle with a fixed combing plate, including a steel strand bundle 3, a fixed combing plate 1, a marking plate and a tightening ring 7, and a tightening ring is fixed on the pulling end of the front end of the steel strand bundle. ring, the tightening ring is fixed coaxially with the steel strand through the tightening sleeve 5; the front and rear ends of the steel strand bundle are respectively equipped with a front marking plate 4 and a rear marking plate 2, and the rear marking plate rear end The coaxial threading on the steel strand can fix the carding board.

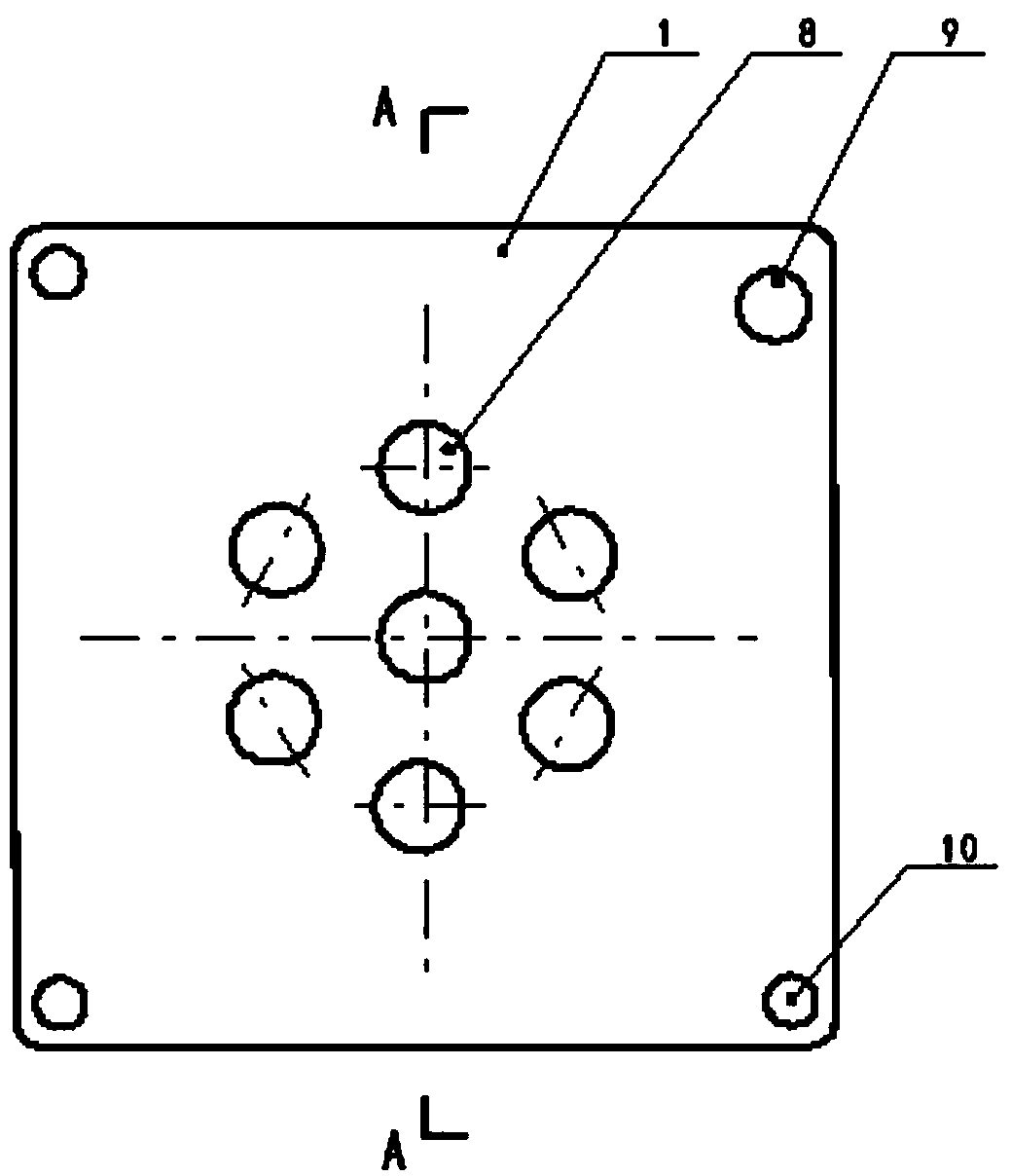

[0018] The fixed combing plate is a plate similar to the connection end face of the anchor backing plate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com