Three-point supporting method for pipe joint prefabricating and pushing construction according to factory method

A three-point support and jacking construction technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve difficult construction conditions, heavy and complex design of jacking mechanism and jacking beam reaction force Problems such as pipe joint construction at the seat and inconvenient turning sections, etc., to improve the efficiency of jacking construction, reduce the risk of jacking construction, and ensure the quality of jacking construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

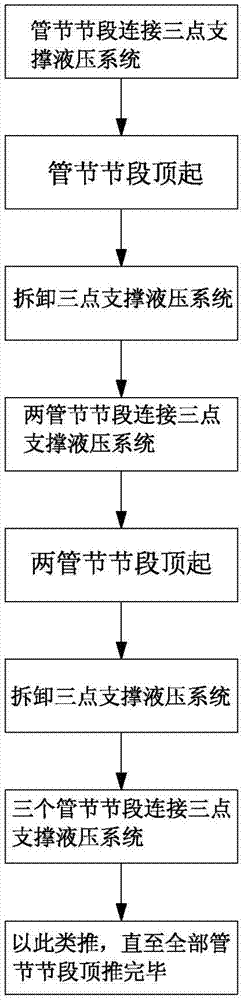

[0041] see figure 1 As shown, the three-point support method of the factory method pipe joint prefabricated jacking construction of the present embodiment comprises the following steps:

[0042] 1. Connect the three-point support hydraulic system to the support jack of the prefabricated pipe section;

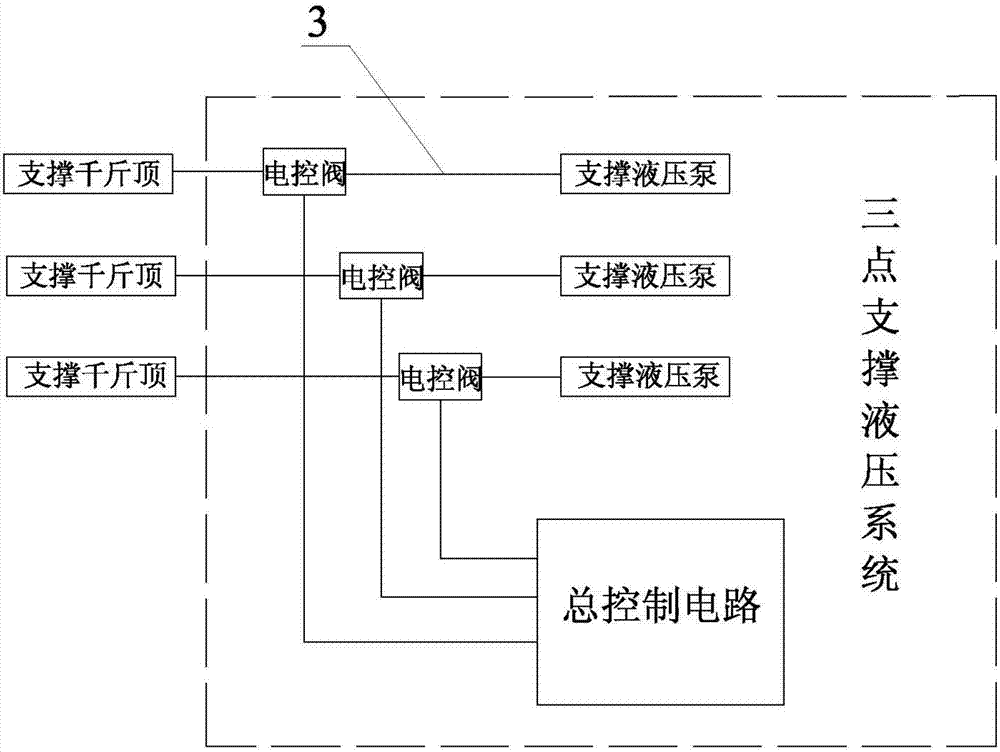

[0043] see figure 2 As shown, the three-point support hydraulic system described in this embodiment includes three support hydraulic pumps for providing support hydraulic pressure for each support jack, a plurality of support pipelines for connecting the support jacks and support hydraulic pumps, and is arranged on The electric control valve on the support pipeline is used to switch and control each support pipeline and the general control circuit for the overall control of the three-point support hydraulic pressure to perform three-point support construction on the pipe section; the electric control valve communicates with the The general control circuit is electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com